Light- and/or heat-stabilized composition

A composition and compound technology, applied in the field of fibers, filaments and/or products, and yarns, can solve problems such as loss of mechanical properties, discoloration, unevenness, etc., and achieve good mechanical properties, excellent dyeing durability, and good dyeing uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Polyamide 66 composition of the invention

[0065] A copolymer based on polyamide 66 was prepared from 1115 kg of a 52% by weight aqueous concentrated solution of hexammonium adipate, to which was added:

[0066] -58g manganese acetate tetrahydrate (label Aldrich: 22,100-7);

[0067] - 20 g of Rhodorsil 411 antifoam;

[0068] - 12.9 kg of caprolactam;

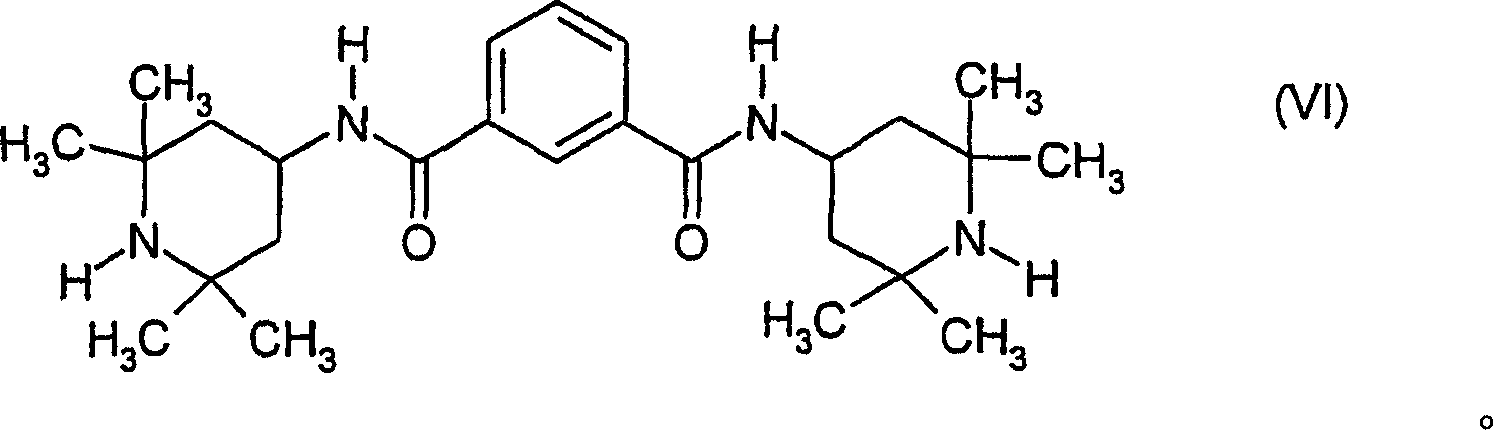

[0069] - 780 g of Nylostab S-EED by Clariant;

[0070] - 257g of adipic acid; and

[0071] -8.8kg uncoated TiO 2 (Hombitan LWS in Sachtleben).

[0072] The polyamide is produced according to a standard method comprising a solution concentration step in an evaporator and a polycondensation step in a stirred autoclave reactor with a static pressure of 18.5 bar at a static pressure of about 100 minutes and a final temperature of 267°C. Distillation stage, depressurization stage from 18.5 bar to 1 bar of about 25 minutes and final temperature of 269°C, and finishing stage of about 26 minutes and final temper...

Embodiment 4

[0090] Example 4: Polyamide 66 composition

[0091] A comparative polyamide 4C was obtained in the same manner from the following base material: A copolymer based on polyamide 66 was prepared from 1115 kg of a 52% by weight aqueous concentrated solution of hexamethylene diammonium adipate, to which was added:

[0092]- 20 g of Rhodorsil 411 antifoam;

[0093] - 12.9 kg of caprolactam;

[0094] - 780g of Clariant's Nylostab S-EED

[0095] - 257g of adipic acid; and

[0096] -8.8kg TiO coated with silica and alumina 2 (Hombitan LOCR-SM from Sachtleben).

[0097] A copolymer based on polyamide 66 containing 2.5% by weight of polyamide 6 units and 1.7% by weight of titanium dioxide is obtained.

Embodiment 5

[0098] Example 5: Spinning and knitting of polyamide compositions

[0099] The polyamide composition obtained in the preceding examples was spun at a take-up speed of 4200 m / min, followed by drawing at a take-up speed of 1070 m / min. The count of the yarn obtained was 101 dtex per 68 filaments before drawing and 82 dtex after drawing.

[0100] For Polyamide 1: The tenacity of the POY yarn before stretching was 34.8 cN / tex and the elongation at break was 75.9%. The tenacity of the drawn yarn was 43.9 cN / tex, and the elongation at break was 43.3%.

[0101] For comparative polyamide 2C: The tenacity of the POY yarn before stretching was 34.5 cN / tex and the elongation at break was 74.2%. The tenacity of the drawn yarn was 43.3 cN / tex, and the elongation at break was 43.9%.

[0102] For comparative polyamide 3C: The tenacity of the POY yarn before stretching was 33.9 cN / tex and the elongation at break was 77%. The tenacity of the drawn yarn was 42.1 cN / tex, and the elongation at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com