Manufacturing method of organic compound particulate

A technology of organic compounds and manufacturing methods, applied in the direction of mixing methods, chemical instruments and methods, medical preparations of non-active ingredients, etc., can solve the problems of drug pollution, yield reduction, noise generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

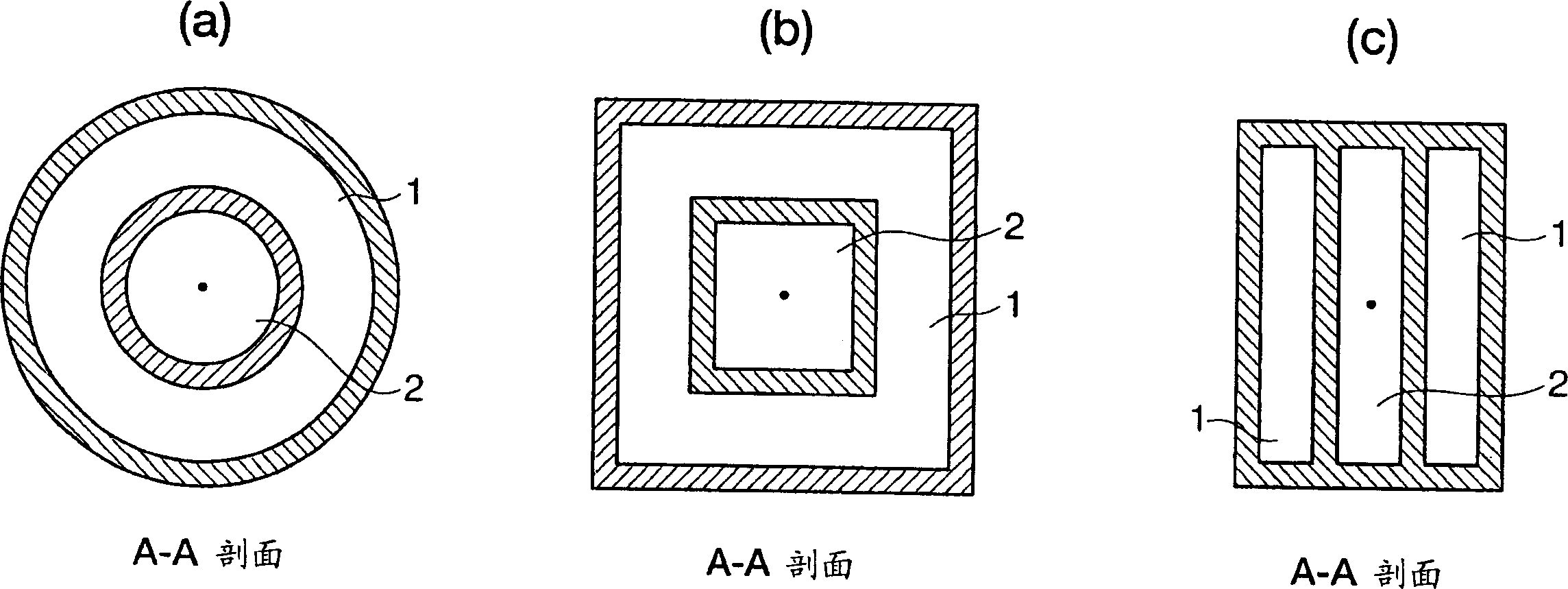

[0077] In the mixing and precipitation step (A), use figure 2 The coaxial mixer with the structure shown in (a) continuously mixes the poor solvent and the organic compound solution to generate a particle suspension. The coaxial mixer is composed of a stainless steel cylindrical tube (7mm inner diameter) that constitutes the main flow path (1), and a stainless steel cylindrical tube (1.6mm outer diameter, inner diameter 0.8mm) that constitutes the introduction flow inside the main flow path (1). (2), and an ultrasonic vibrator (4a) (ultrasonic radiator with a diameter of 20mm ) is inserted into the large-diameter mixing chamber (3) so that it is located 5 mm directly above the overflow port of the introduction flow path (2), so that the poor solvent supplied to the main flow path (1) and the poor solvent supplied to the introduction flow path ( 2) The organic compound solution is contacted and mixed in the mixing chamber (3) under ultrasonic irradiation, thereby generating f...

Embodiment 6

[0089] Indomethacin (water solubility of 1 mg / mL or less) which is a poorly water-soluble organic compound was dissolved in ethanol (purity: 99.5%) as a good solvent to obtain a drug concentration of 10 mg / mL drug solution. Desalted water was used as a poor solvent, and sodium lauryl sulfate as a dispersion stabilizer was dissolved in desalted water (0.625 mg / mL). Using a coaxial mixer with the same double tube structure as in Examples 1 to 5, the poor solvent was supplied to the main flow path (1) at 76mL / min, and the drug solution was supplied to the introduction flow path (2) at 2mL / min. Ultrasonic waves (20kHz, 150W) are irradiated to the contact area of the two liquids to generate a particle suspension at room temperature (about 25°C). Immediately measure the generated particle suspension with a dynamic light scattering particle size distribution meter ("HPP5001" (trade name) manufactured by Malvern Co., Ltd.), and the volume average particle diameter is 0.81 μm. In ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com