Method for purifying salvianolic acid B

A technology of salvianolic acid and salvia miltiorrhiza, applied in the field of extraction and separation and purification of natural products, can solve the problems of difficulty in ensuring drug safety, many separation process steps, and long extraction time with water, so as to avoid degradation and bacterial contamination, and reduce process steps , the effect of reducing the dissolution of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

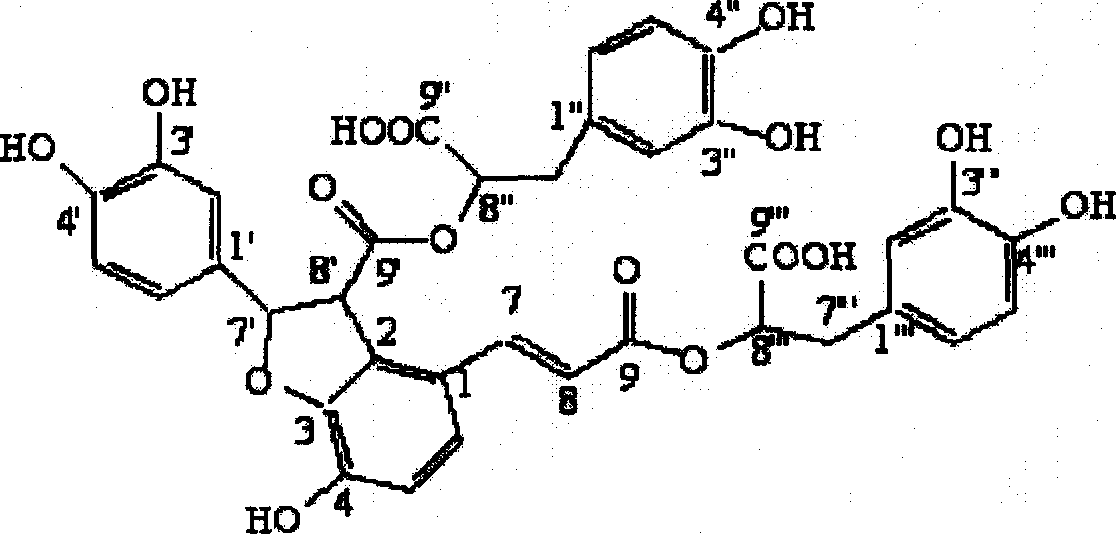

Image

Examples

Embodiment 1

[0021] Take 150g of fresh medicinal materials of Salvia miltiorrhiza (with a slice length of about 3cm) and treat them with medium heat for 8 minutes in a microwave field with a frequency of 2450 Hz. 80g of Salvia miltiorrhiza is sun-dried and extracted with 800ml of water. The extract is filtered with gauze and centrifuged at 3000rpm to remove impurities. The centrifugal fluid is placed on a polyamide column (25×600mm). The resin bed volume is 250ml. First use 750ml of water and 250ml. 20% ethanol and 375ml 50% ethanol were eluted to remove impurities, and then salvianolic acid B was eluted with 375ml 70% ethanol. The eluate containing salvianolic acid B was collected and concentrated under reduced pressure and freeze-dried. Salvianolic acid B with a purity of 98.5% was obtained.

Embodiment 2

[0023] Salvia medicinal materials are crushed and passed through a 40 mesh sieve. Take 30g of Salvia miltiorrhiza powder, add 300ml of water, and treat it in a microwave field with a frequency of 2450 Hz for 3 minutes. After filtering with gauze, it is centrifuged at 3000 rpm to remove impurities, and the centrifugal liquid is placed on a polyamide column (25× 600mm), the resin bed volume is 100ml, first use 300ml water, 100ml 20% ethanol and 150ml 50% ethanol to elute and remove impurities, and then use 400ml 70% ethanol to elute the salvianolic acid B, and collect the salvianolic acid The eluate of B is concentrated under reduced pressure and freeze-dried to obtain salvianolic acid B with a purity of 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com