Optical fiber output laser and uses thereof

A laser and optical fiber technology, applied in lasers, laser parts, laser parts and other directions, can solve the problems of high-quality product processing affecting the performance of parallel machine tools, inaccurate processing points, large resistance, etc., to achieve compact structure and small system volume. , The effect of processing the reaction force is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Describe the present invention in detail below in conjunction with embodiment and accompanying drawing thereof, but the present invention is not limited by embodiment:

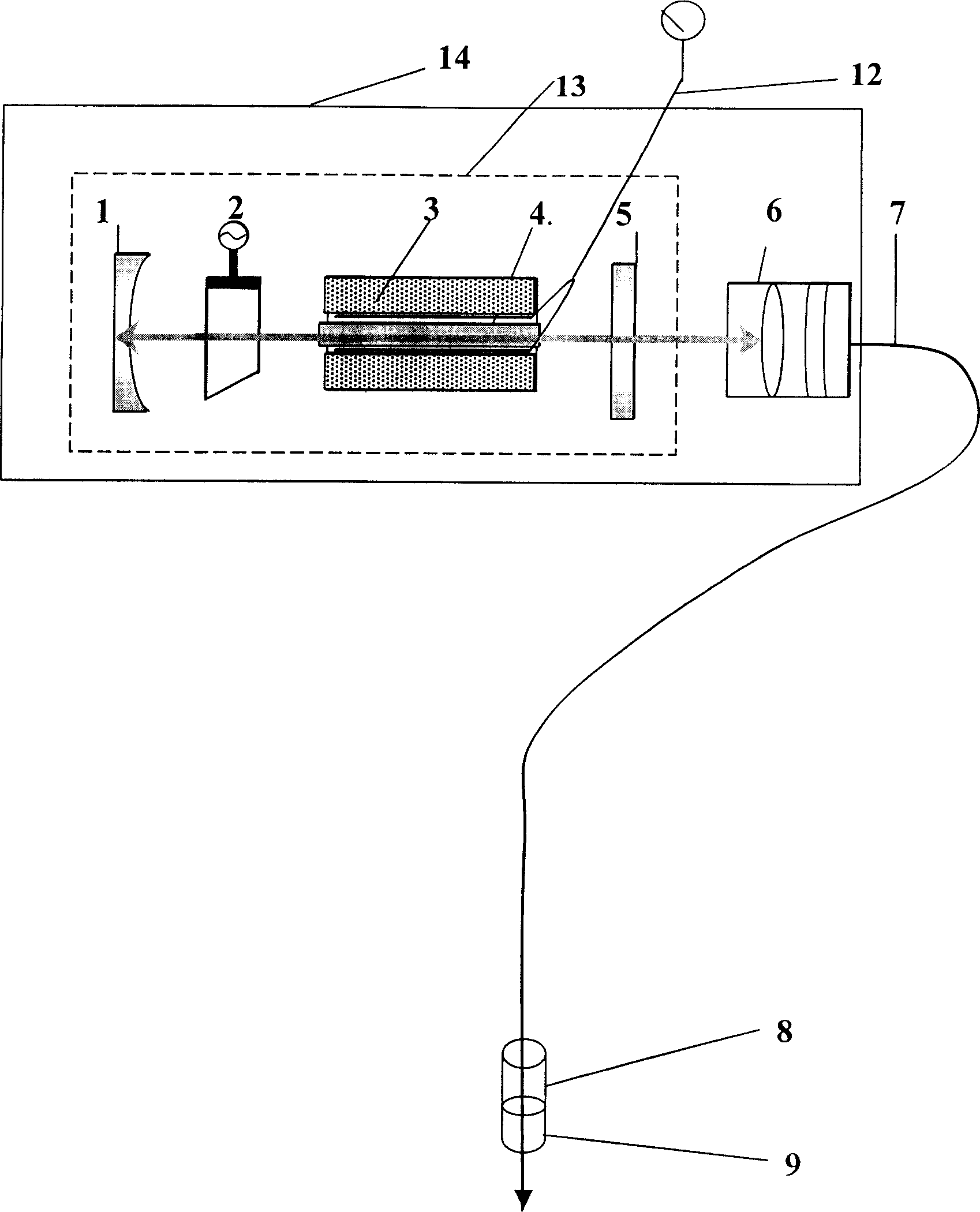

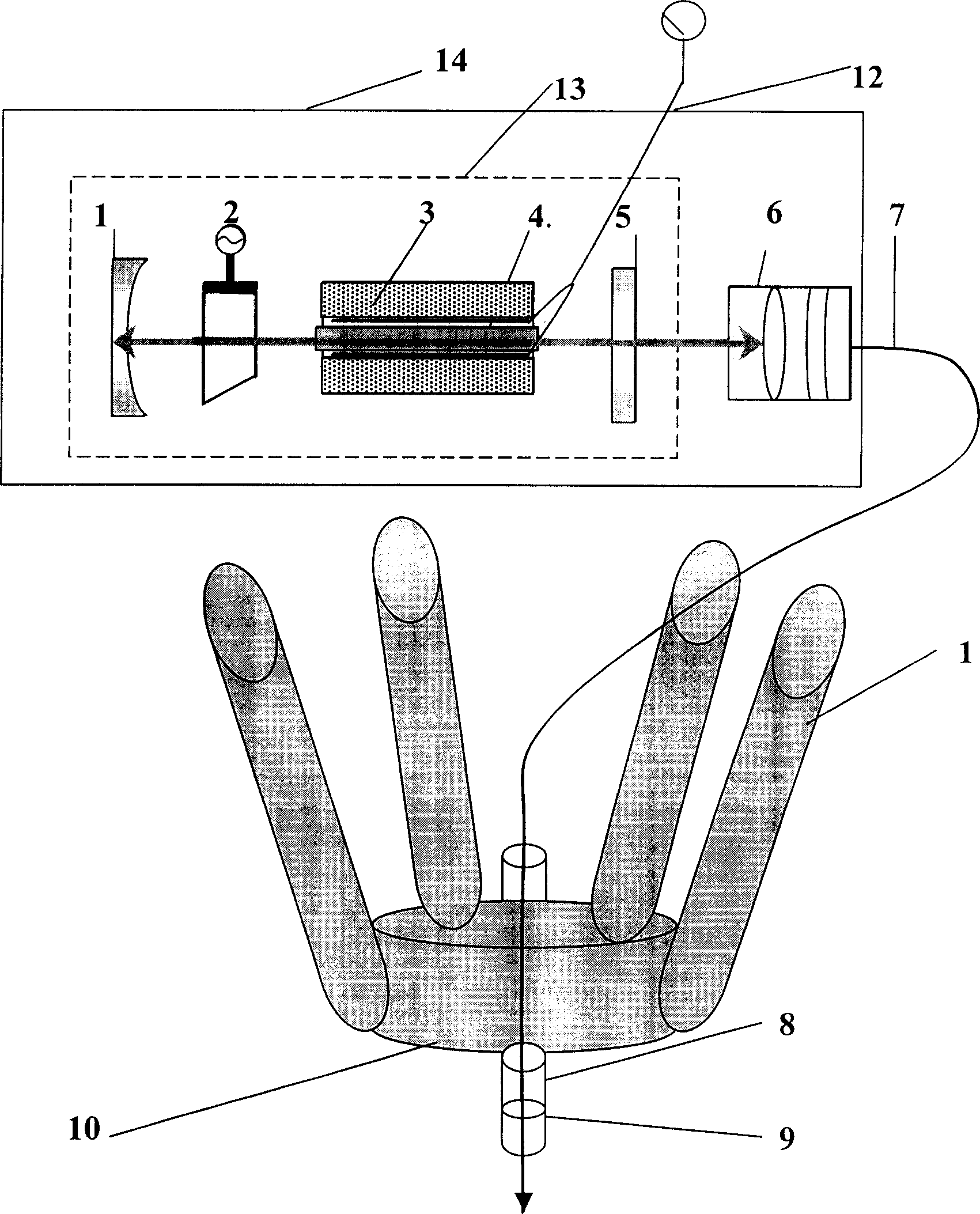

[0014] Optical fiber output laser of the present invention (hereinafter referred to as laser, see figure 1 ), characterized in that the laser includes a box body 14 and a laser resonant cavity 13 and a fiber coupling device 6 installed therein, the length of the laser resonant cavity 13 is adjustable within the range of 385-580 mm, and the middle of it is installed with Nd:YAG laser rod 4, pump laser power supply 3 and water-cooled thermostat 12 components, the output side of the component is installed with a flat output mirror 5; the non-output side of the component is sequentially installed with an acousto-optic Q switch 2 and a concave full reflection mirror 1; the installation or adjustable position of the concave total reflection mirror 1, the acousto-optic Q switch 2, Nd:YAG laser rod 4, the plane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com