Method for preventing clearance generation between different materials in semiconductor device

A semiconductor and device technology, applied in the field of preventing gaps between different materials in semiconductor devices, can solve the problems of incomplete corrosion of the W layer and inability to form memory unit contacts, etc., to eliminate the reduction in yield and stabilize the source and drain The effect of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

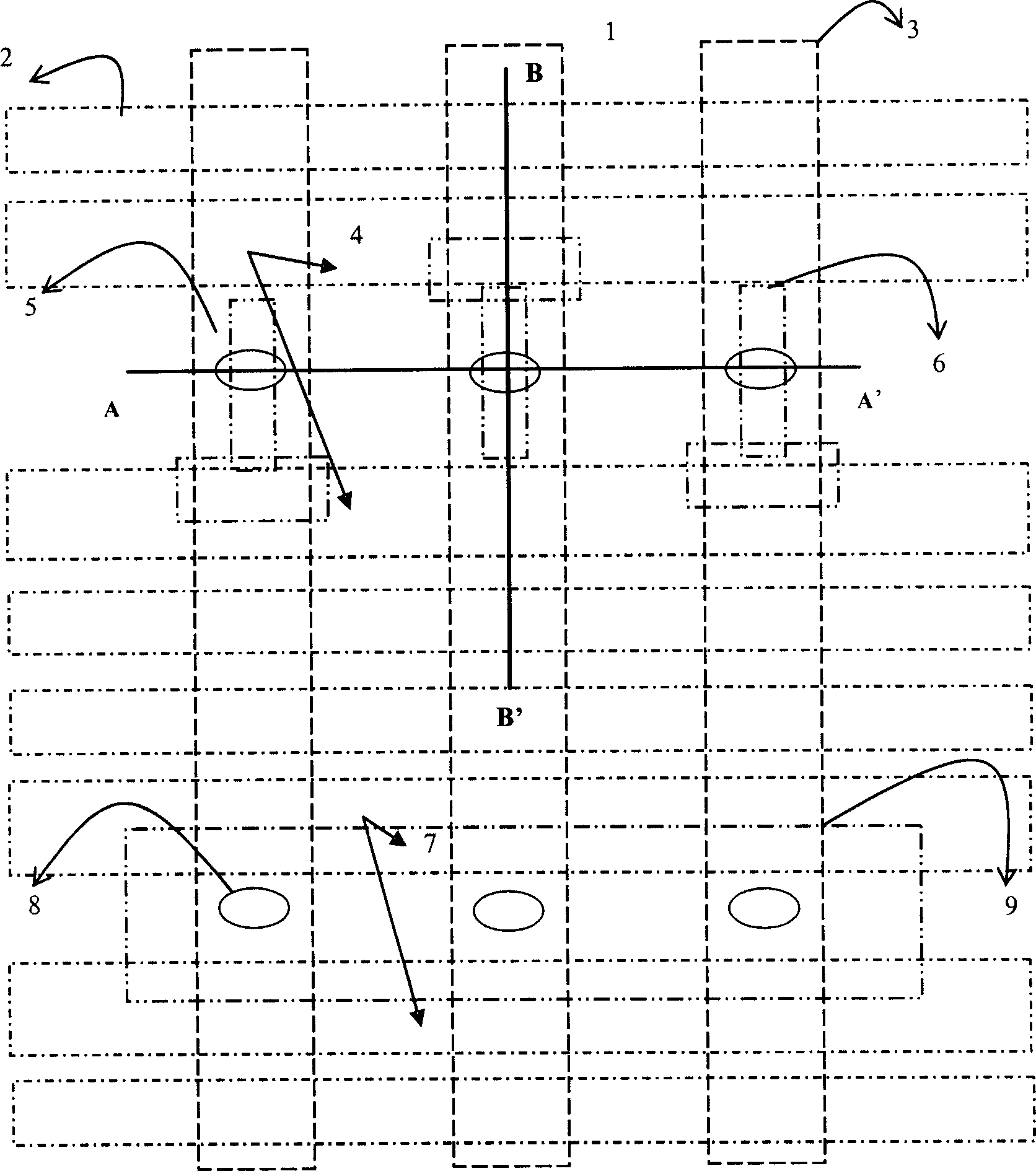

[0066] see below Figure 10 to Figure 17 The method of the present invention is described in detail, taking the manufacturing method of the memory unit contacts in the 0.18 μm NAND flash memory as an example to describe the present invention in detail.

[0067] Figure 10 After determining the gate in the 0.18 μm “NAND” flash memory, the 0.18 μm “NAND” flash memory structure after depositing and reflowing phosphoborosilicate glass (BPSG) for the first time by the manufacturing method of the present invention figure 1 The schematic diagram of the cross-sectional structure cut by the B-B' line in the middle, and Figure 4 same;

[0068] Figure 11 It is the 0.18 μm "NAND" flash memory structure after the first photolithographic etching of the memory cell contact (CCT) according to the method of the present invention. figure 1 The cross-sectional schematic diagram cut by the line B-B′ in the middle, and Figure 5 same;

[0069] Figure 12 It is the 0.18 μm "NAND" flash mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com