Resin composition for laser welding and molded article

A technology of resin composition and laser welding, which is applied in the field of polybutylene terephthalate resin composition, can solve problems such as inability to weld, time loss and environmental burden, and achieve high uniformity of welding and laser welding Excellent depositability and high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

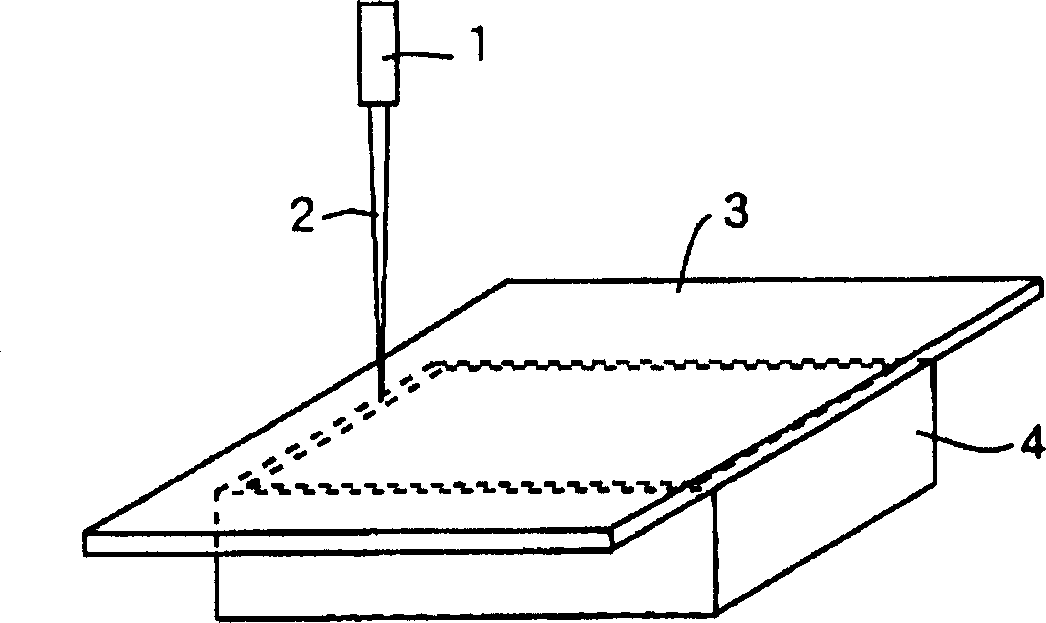

Image

Examples

Embodiment 1-10 and comparative example 1-2

[0098] In the examples and comparative examples, the following PBT resin (A), elastomer (B), polycarbonate resin (C), plasticizer (D), filler or reinforcing agent (E), Nucleating agent (F) and coloring agent.

[0099] PBT resin (A)

[0100] (A-1) Dimethyl isophthalate (DMI) modified PBT resin

[0101] In the reaction of terephthalic acid and 1,4-butanediol, 12.5 mol% of DMI was used as a copolymer component instead of a part of terephthalic acid (12.5 mol%) to prepare modified polybutylene terephthalate Diester.

[0102] Elastomer (B)

[0103] (B-1) Epoxy-containing polystyrene thermoplastic elastomer ESBS ["EPOFRIEND AT504" manufactured by Daicel Chemical Industry Co., Ltd.]

[0104] (B-2) Polyester thermoplastic elastomer ["GP200" manufactured by Toyobo Co., Ltd.]

[0105](B-3) Polystyrene-based thermoplastic elastomer [Kuraray Co., Ltd. product "Septon 4055"]

[0106] Polycarbonate resin (C)

[0107] (C-1) Polycarbonate resin ("PANLITE L-1225" manufactured by Teijin Chemical Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com