Lamp for vehicle

A technology for lamps and vehicles, which is applied in household appliances, vehicle parts, vehicle lighting systems, etc., can solve the problems of high manufacturing cost, high cost, and complex formation process of light reflection film, and achieve low cost and high welding strength , The effect of simplifying the film forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

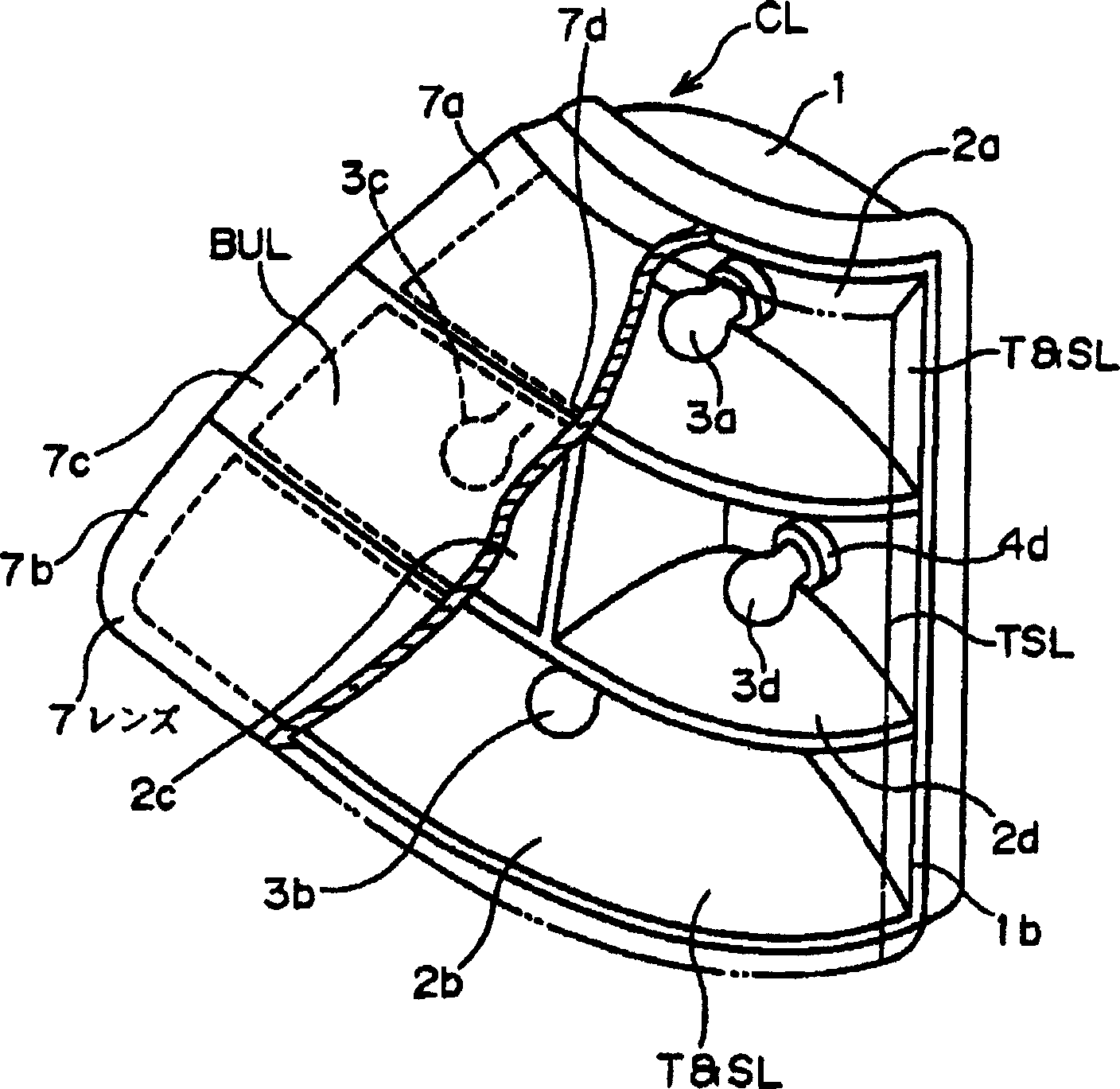

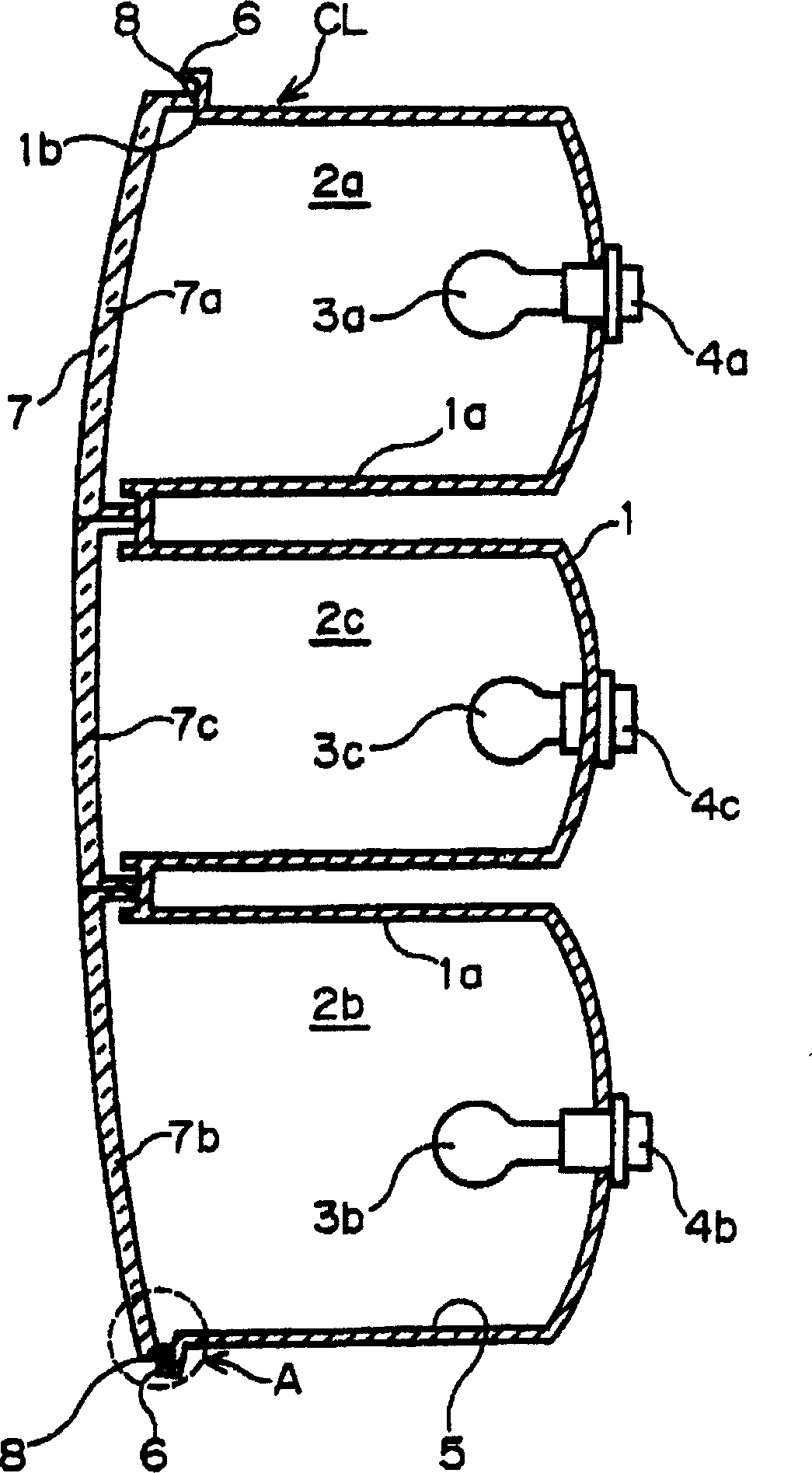

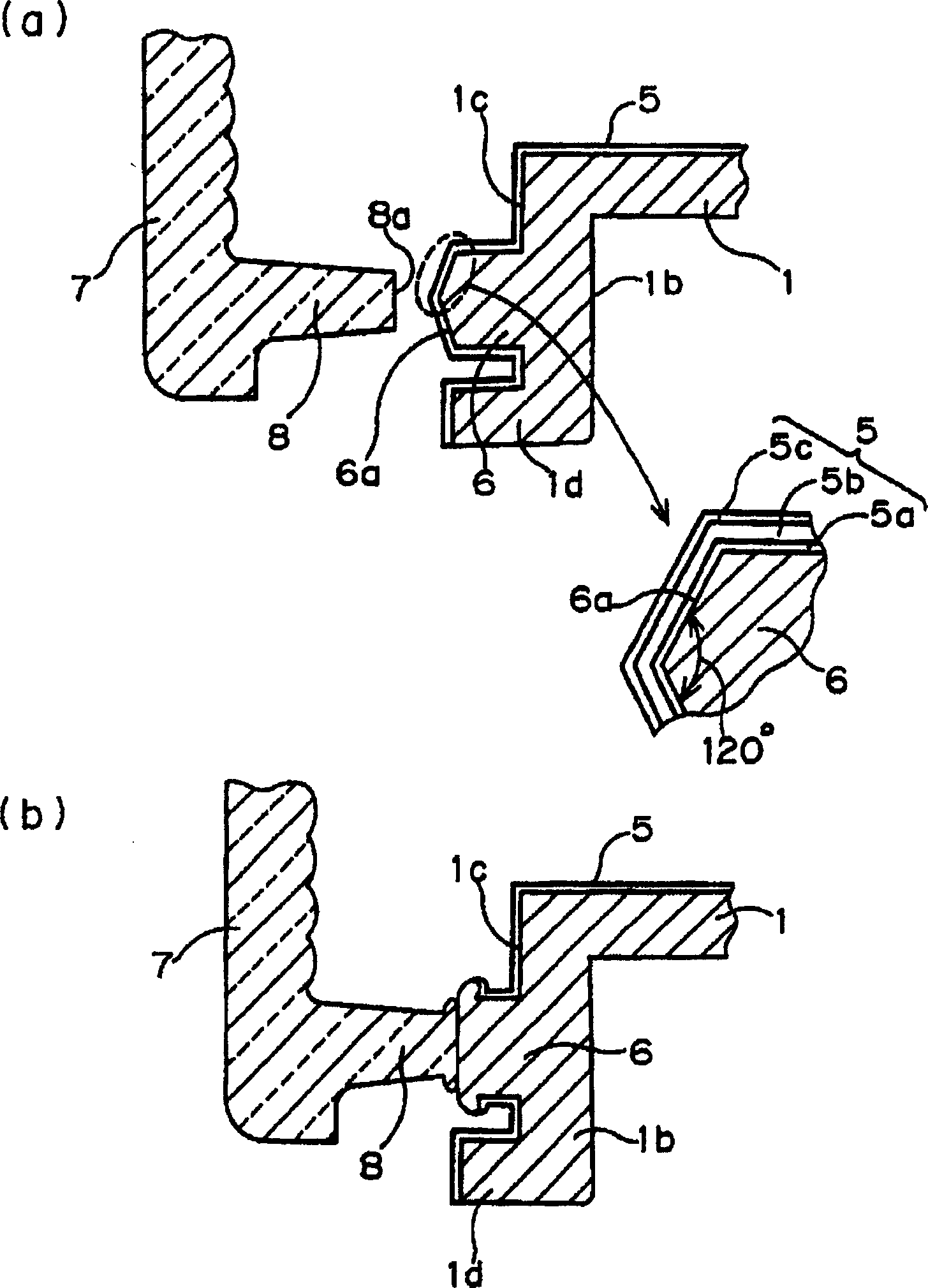

[0015] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a partial sectional perspective view showing an embodiment of a composite lamp CL which applies the present invention to an automobile tail lamp and a rear combination lamp which integrates a tail lamp, a parking lamp, a reverse lamp, and a turn signal lamp here, figure 2 is its longitudinal section. The above-mentioned composite lamp CL divides the inside of the lamp body 1 integrally molded with thermoplastic resin into four lamp chambers 2a-2d by means of the partition wall 1a, and at the same time installs bulbs in each lamp chamber 2a-2d through the bulb sockets 4a-4d, respectively. 3a to 3d constitute the above-mentioned tail light and stop light T&SL, back light BUL, and turn signal light TSL, respectively. Among them, the lamp body 1 is divided into upper, middle and lower sections, and taillights and parking lights T&SL are arranged in the upper and lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com