Metal oxide semiconductor field-effect transistor with isolating structure and its production

一种氧化物半导体、场效晶体管的技术,应用在金属氧化物半导体场效晶体管领域,能够解决制造过程复杂、高制作成本等问题,达到高击穿电压、低导通阻抗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

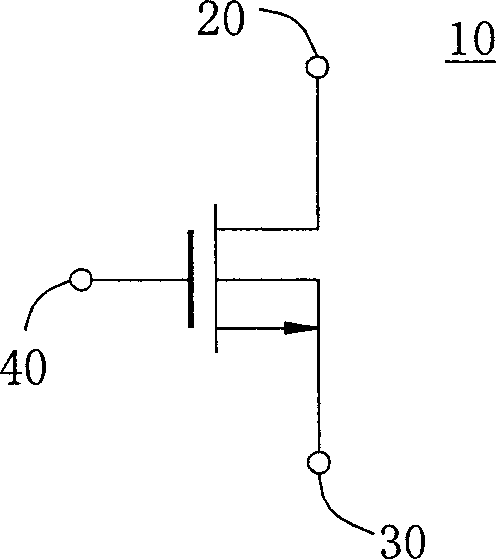

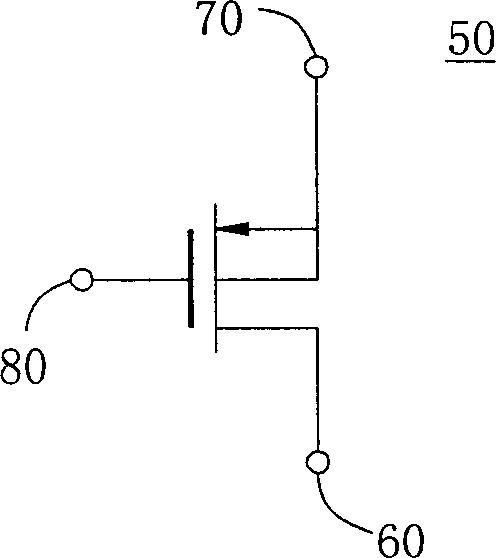

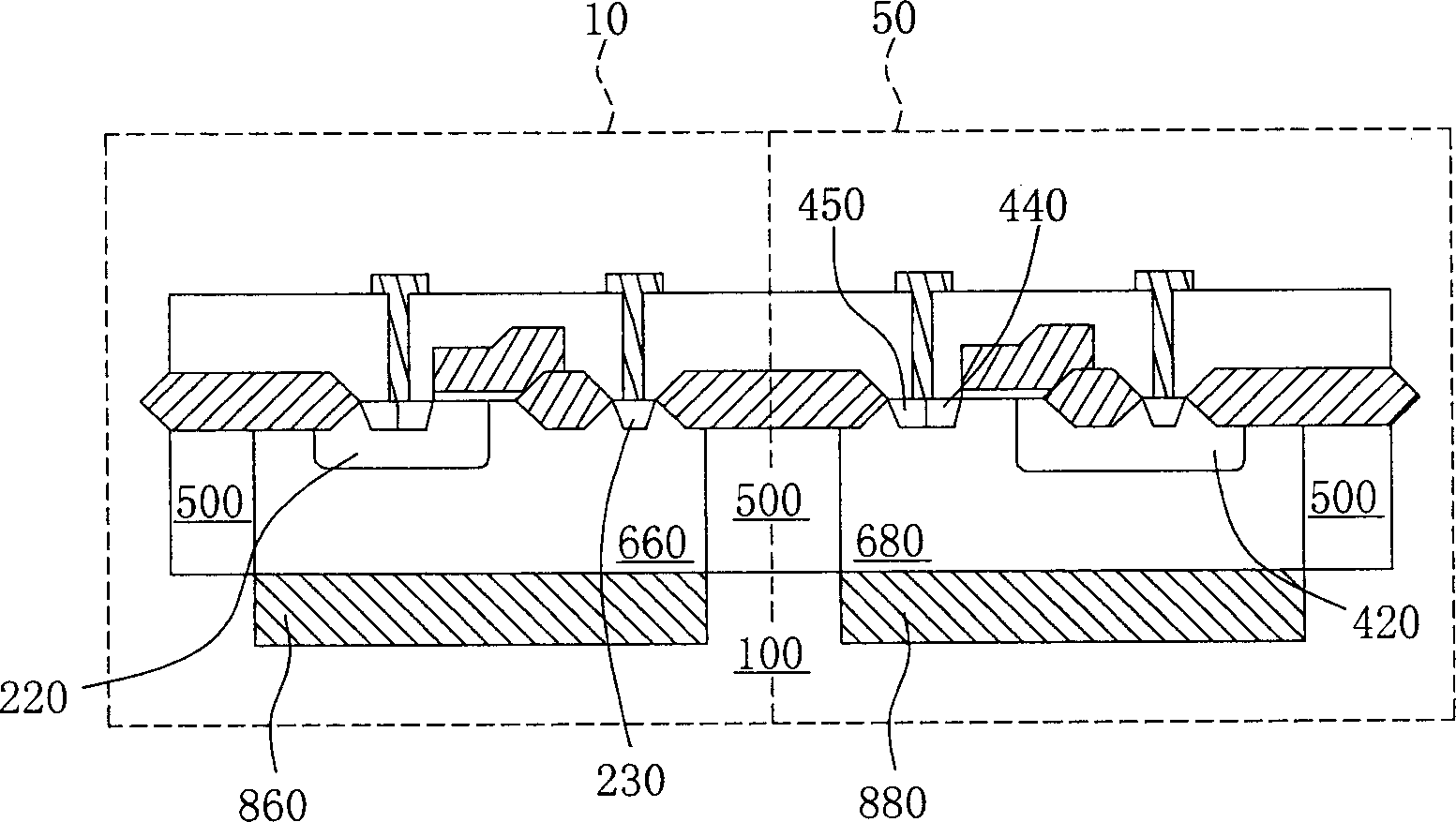

[0087] see Figure 4 and Figure 5 As shown, it is a schematic top view of the area and a schematic cross-sectional view of the structure of the metal oxide semiconductor field effect transistor of the present invention. As can be seen from the figure, the present invention provides an N-type metal oxide semiconductor field effect transistor 10, which at least includes: a P-type substrate 100, a first N-type embedded layer (buried layer) 101 and a P-type epitaxial layer (epitaxial layer) 90 is placed in the P-type substrate 100, a first N-type diffusion region 21 with N-type conductive ions forms a first N-type well 210 in the first N-type embedded layer 101, a first N-type well 210 with The first P-type diffusion region 22 of P-type conductive ions forms a first P-type region 220 in the first N-type well 210, and a first drain diffusion region 23 with N+ type conductive ions forms in the first N-type well 210. A first drain region 230 is formed in the diffusion region 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com