Hardened and toughened nut

A screw and super-tough technology, applied in the direction of screws, nuts, bolts, etc., can solve the problems of insufficient bearing capacity, easy to break, low hardness, etc., and achieve the effect of significant social benefits, low cost, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

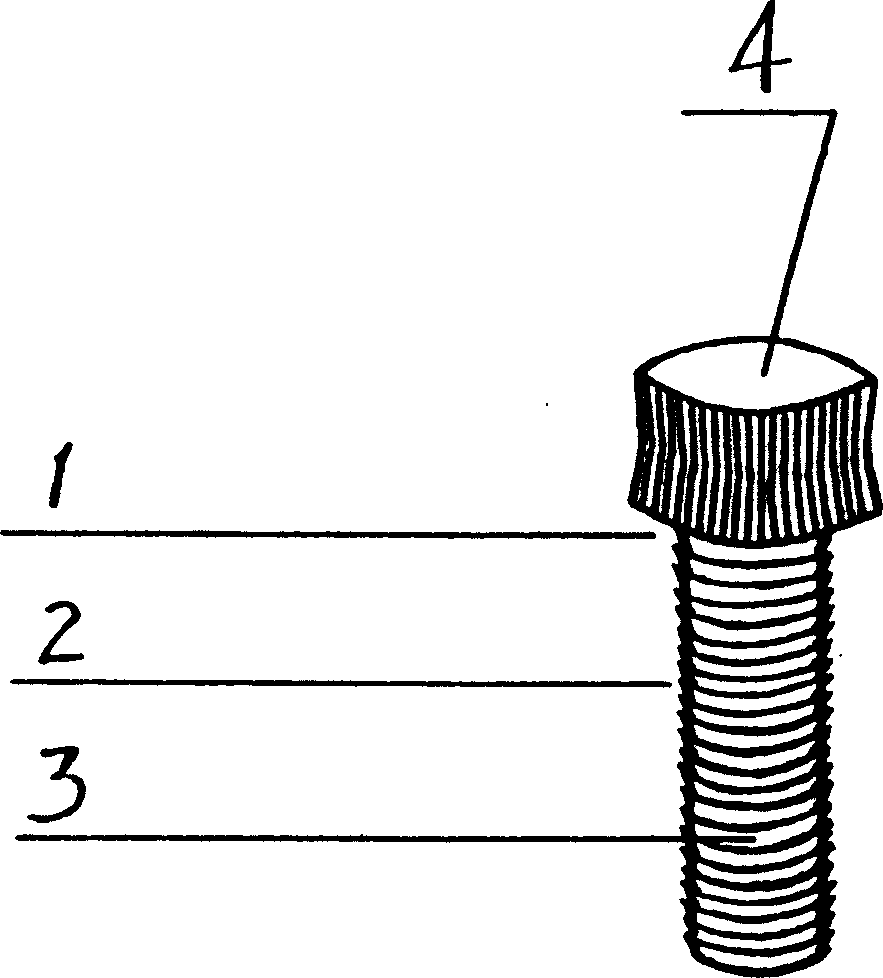

[0014] exist figure 1 The screw body 1 of the non-standard screw is respectively provided with a screw shank 2 , a screw shank thread 3 and a nail top 4 of a conjoined structure.

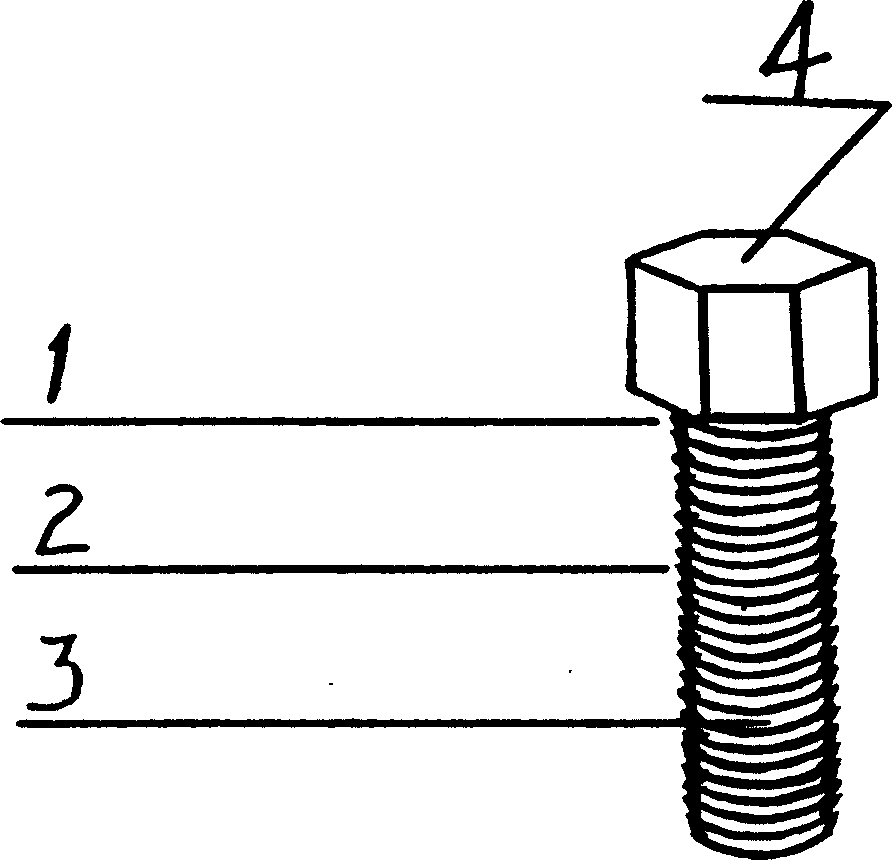

[0015] exist figure 2 The body 1 of the national standard screw is also provided with a screw shank 2 , a screw shank thread 3 and a nail top 4 with a conjoined structure.

[0016] Whether it is a non-standard screw or a national standard screw, it can be made of 20 chromium steel, 40 chromium steel or 20 chromium manganese titanium steel, or it can be made of 10 chromium manganese titanium steel with a carbon content of about 1‰; Hard on the outside and tough on the inside, no matter what kind of steel is used in the present invention, it can be quenched by heat treatment and quenching process or carburizing and quenching process in heat treatment.

[0017] The hardness and depth of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com