Production and producer for nanometer carbon liquid

A nano-carbon and equipment technology, applied in mixing methods, chemical instruments and methods, dissolution and other directions, can solve the problems of complex equipment, cumbersome process, unable to guarantee quality agglomeration, etc., and achieve long service life, simple preparation method, and improved conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

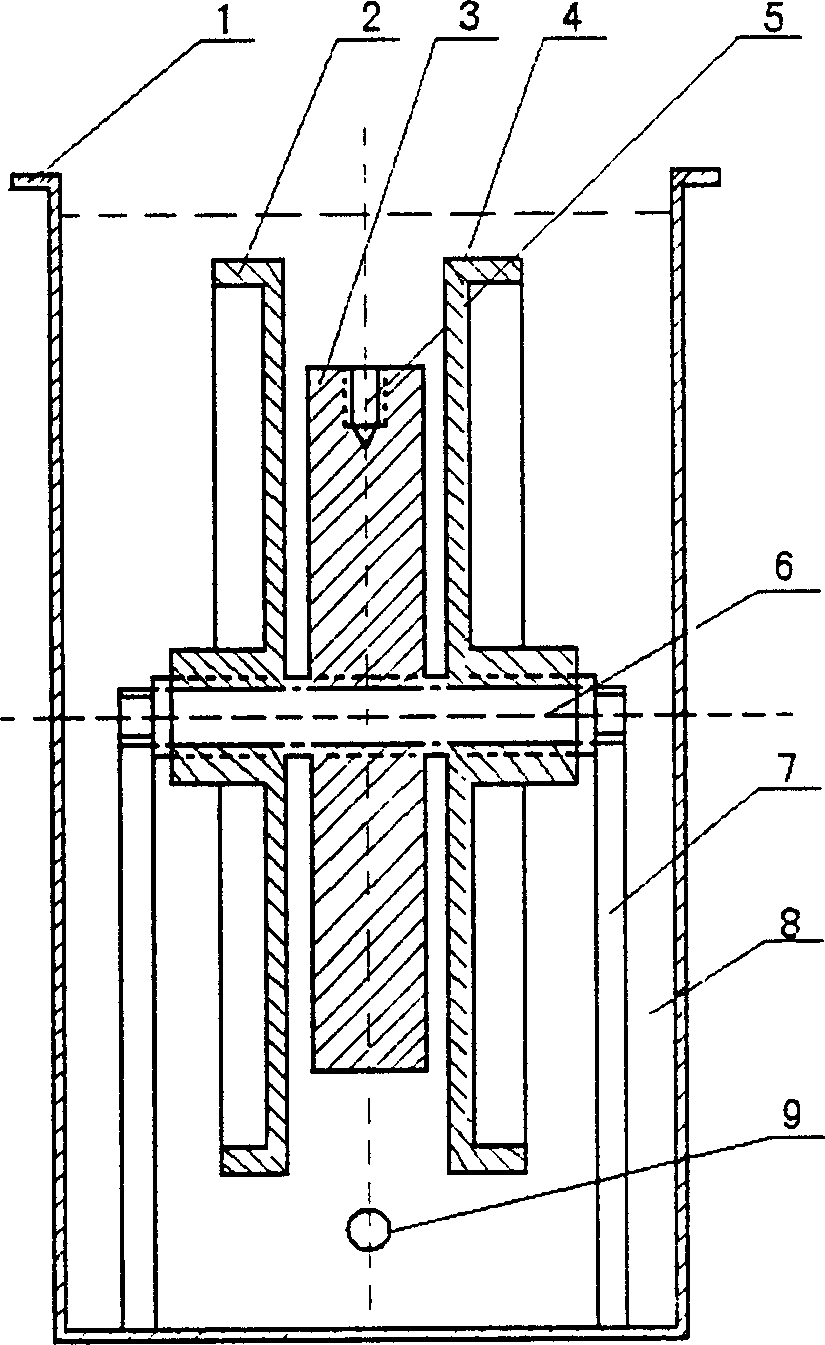

[0006] see figure 1 , the preparation method of the nano-carbon liquid of the present invention, comprising:

[0007] The first step of material preparation: (1) Purify the water, and purify the water in the water production workshop to obtain deionized pure water with a pH value of 6.5-7.2 and a resistance value of 1MΩ-50MΩ. The resistance value is 18MΩ or more. (2) prepare the pole plate, select graphite carbon, require the purity of graphite carbon to be 99.99%, the ash content to be less than 100PPM, the fineness to be above 300 mesh, and the strength to be above 58mpa, and processed according to the requirements of the pole plate geometry;

[0008] Trial run before the second step of processing: use the processed graphite carbon plate as the positive plate, set metal negative plates on both sides, keep a certain gap between the positive plate and the two negative plates, and then put the prepared deionized Soak in pure water for 24 hours, turn on electricity, test whethe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com