2-substituted cubic-phase zirconium tungstate solid solution temperature-sensitive dispersion compensation porcelain body and preparing method therefor

A technology of dispersion compensation and ceramic body, which is applied in the fields of double-substituted zirconium tungstate ceramic body and its preparation, heat-shrinkable ceramic body and its preparation, and can solve the problem of component deviation from stoichiometric ratio, complex process, and poor compactness of ceramic body and other problems to achieve the effect of reducing the pressure and simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

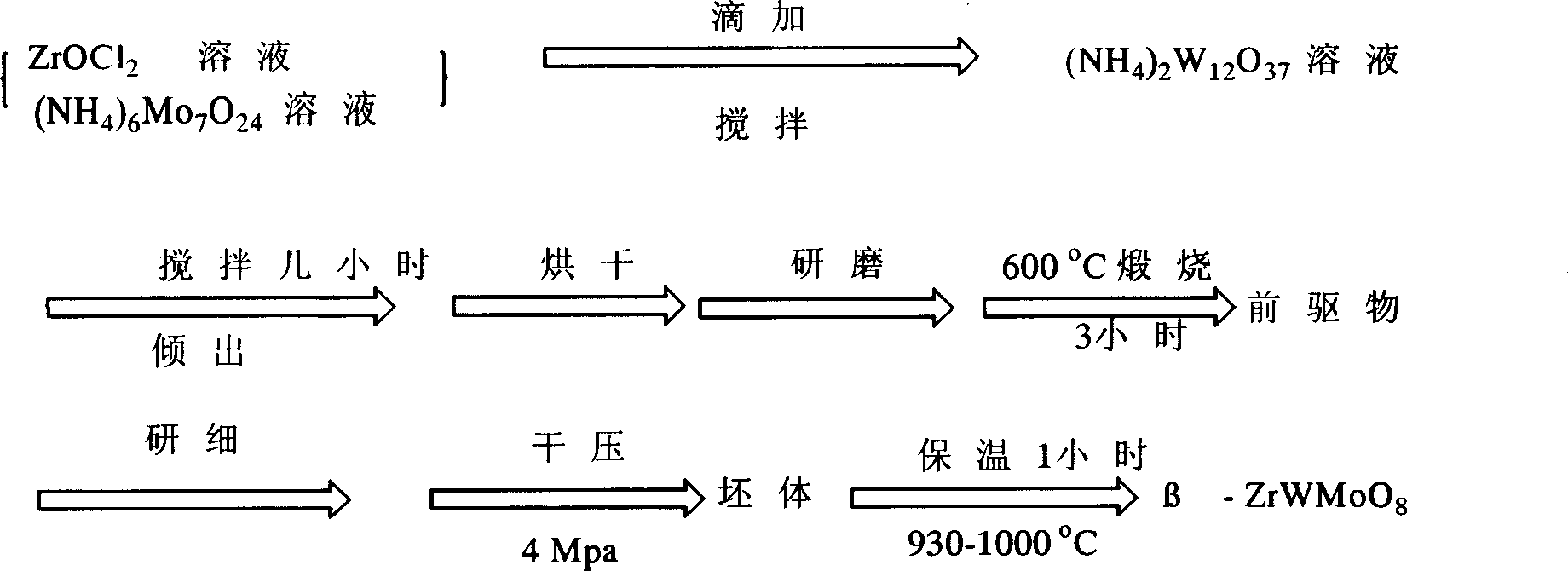

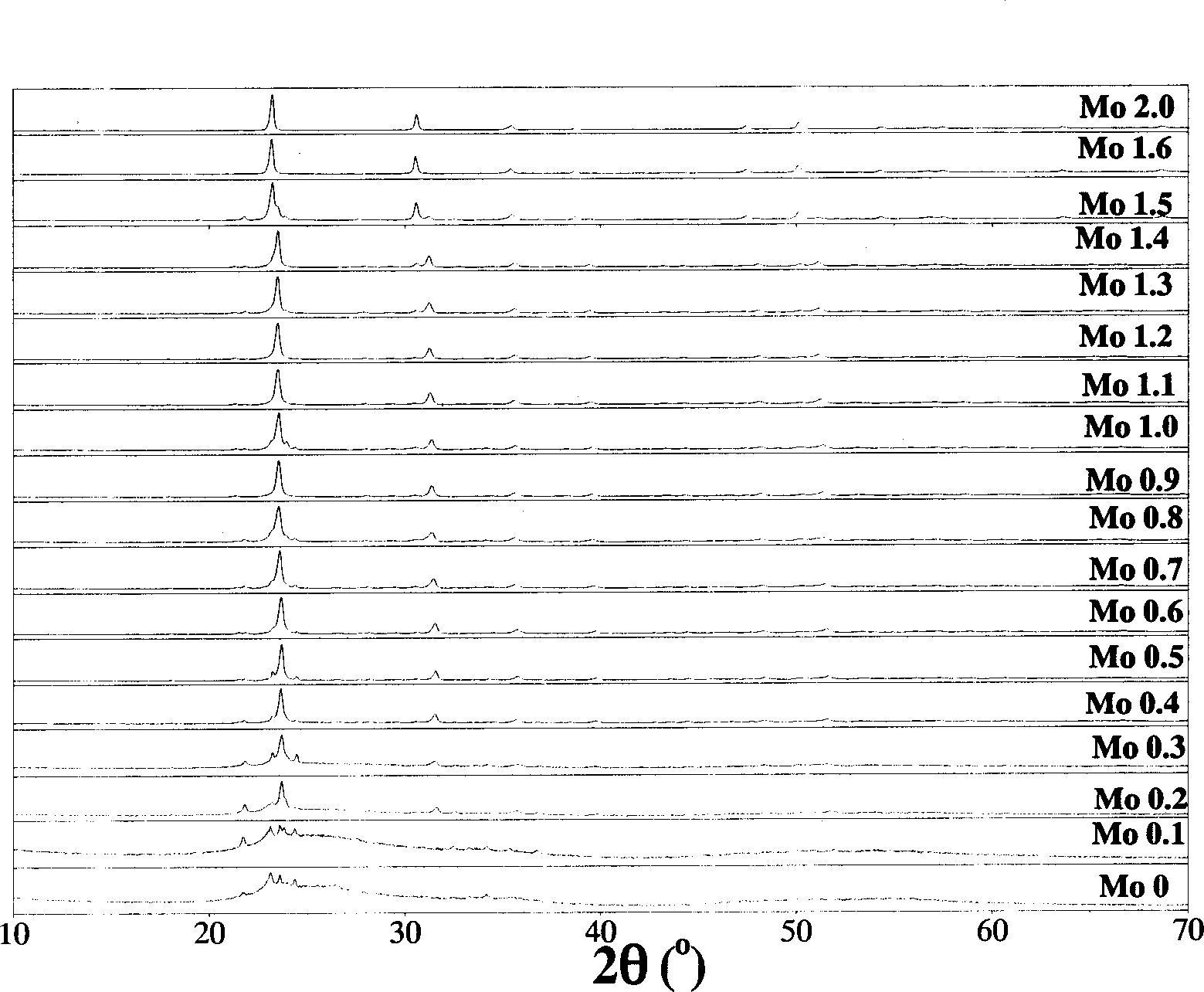

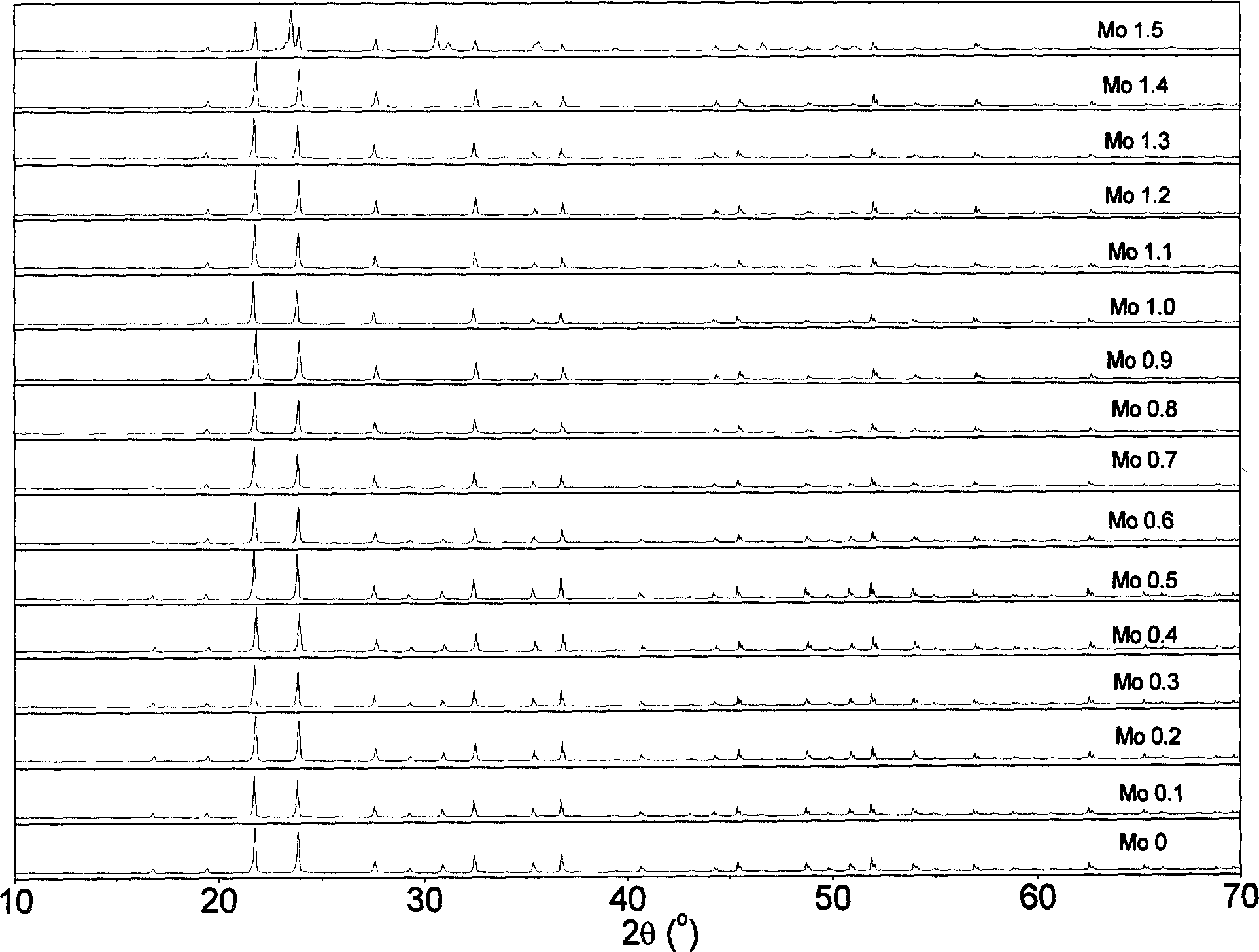

[0046] Example 1 Zirconium tungstomolybdate ZrW 2-y Mo y o 8 (y=0-1.3) preparation of ceramic body

[0047] According to the stoichiometric ratio of the molecular formula, add ammonium paratungstate to a three-necked bottle filled with 20ml of deionized water, and stir; dissolve zirconium oxychloride and ammonium molybdate in 30ml of deionized water, and add it dropwise to ammonium paratungstate at the same time with a constant pressure funnel The solution was stirred for several hours. Dry the co-precipitation, grind it finely, and calcinate at 600°C for 3 hours to obtain the precursor, take out the precursor and grind it, the characteristic X-ray diffraction of the obtained precursor is as follows: figure 2 shown. Weigh about 0.6g of the precursor and put it into a stainless steel mold coated with lubricant, first use a pressure of 2MPa, and then use a pressure of 4MPa for a few minutes to uniaxially dry press it into a green body. First put the green body in a platinum...

Embodiment 2

[0048] Example 2 Zr 0.96 Yb 0.04 wxya 7.98 Preparation of Ceramic Body

[0049] Add 5.2095g of ammonium paratungstate into a three-necked bottle filled with 20ml of deionized water, stir; weigh 0.1576g of Yb 2 o 3 Put into 5ml of concentrated nitric acid and heat to dissolve; 6.1273g of zirconium oxychloride and 3.5466g of ammonium molybdate were dissolved in 30ml of deionized water respectively, and were added dropwise to the ammonium paratungstate solution at the same time with a constant pressure funnel, and then the prepared Yb(NO 3 ) 3 Add dropwise to the coprecipitate and continue stirring for several hours. The co-precipitation was dried, ground into fine powder, and calcined at 600° C. for 3 hours to obtain the precursor. Take out the precursor and grind it, weigh about 0.6g and put it into a stainless steel mold coated with lubricant, first use a pressure of 2MPa, and then use a pressure of 4MPa for a few minutes to uniaxially dry press it into a green body. Fi...

Embodiment 3

[0050] Example 3 moisture resistance

[0051] Soak the three ceramic bodies prepared in Example 2 in deionized water for 120 hours, take them out, dry the water with paper, and calculate the water absorption rate of the ceramic bodies to be 2.8% according to the mass before and after soaking. After immersion, no microcracks appeared in the ceramic body, indicating that the ceramic body had good moisture resistance. Use TMA to raise the temperature from 25°C to 300°C at a rate of 3°C / min and then drop it to 50°C at the same rate to measure the thermal expansion and thermal hysteresis of the ceramic body before and after immersion ( Figure 8 a, b are the thermal expansion and thermal hysteresis curves of the ceramic body before and after soaking respectively), and the expansion coefficients are -4.2×10 -6 / °C and -4.5×10 -6 / °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of expansion | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com