Production process of no-carbon copy paper

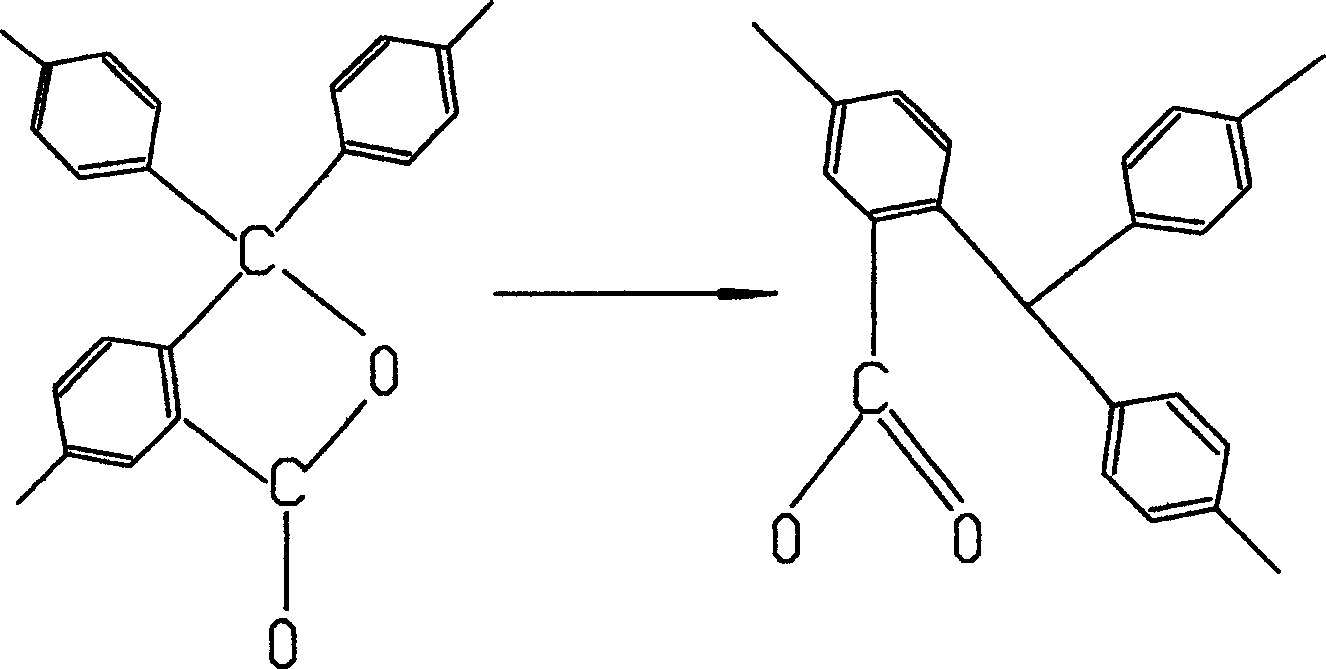

A technology of carbonless copy paper and processing method, which is applied in the directions of paper, papermaking, paper coating, etc., can solve the problems of poor light resistance, single component, easy oxidation, fading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

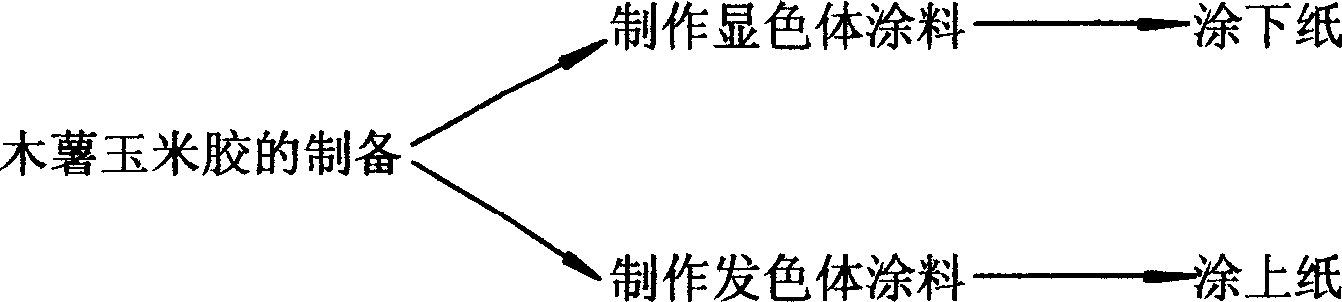

[0020] Embodiment 1, the preparation of cassava corn gum, pour appropriate amount of water into the jar, then pour appropriate amount of tapioca starch and cornstarch into the jar, stir evenly after 10 minutes, then add water, the total weight of tapioca starch and cornstarch The weight ratio to water is 1:8, heat with steam, slowly heat up to 80°C, heat up for 1 hour, keep warm for 25 minutes, then cool to room temperature; make chromogenic paint, pour cassava corn gum into the preparation tank , while stirring, the mixture of activated clay, calcium carbonate and china clay inorganic compound is added to the preparation tank, and the resin is added to the preparation tank after 25 minutes, and after mixing evenly for 30 minutes, the latex is continuously stirred at a slow speed. Ratio: 30 parts of inorganic compound mixture, 15 parts of resin, 35 parts of latex and cassava corn gum, and finally add an appropriate amount of defoamer; make color body paint, mix microcapsules, s...

Embodiment 2

[0021] Embodiment 2, the preparation of cassava corn gum, pour appropriate amount of water into the jar, then pour appropriate amount of tapioca starch and cornstarch into the jar, after stirring for 15 minutes, add water, the total weight of tapioca starch and cornstarch The weight ratio of water to water is 1:10, heat with steam, slowly heat up to 90°C, heat up for 2 hours, keep warm for 30 minutes, then cool to room temperature; make chromogenic paint, pour cassava corn gum into the preparation tank , while stirring, the mixture of activated clay, calcium carbonate and china clay inorganic compound is added to the preparation tank, and the resin is added to the preparation tank after 30 minutes. After mixing evenly for 30 minutes, the latex is continuously stirred at a slow speed. Ratio: 39.5 parts of inorganic compound mixture, 17.5 parts of resin, 44.5 parts of latex and tapioca corn gum, and finally add an appropriate amount of defoamer; make color body paint, mix microca...

Embodiment 3

[0022] Embodiment 3, the preparation of cassava corn gum, pour appropriate amount of water into the jar, then pour appropriate amount of tapioca starch and cornstarch into the jar, after stirring for 20 minutes, add water, the total weight of tapioca starch and cornstarch The weight ratio to water is 1:12, heat with steam, slowly raise the temperature to 100°C, the heating time is 3 hours, keep warm for 35 minutes and then cool to room temperature; make chromogenic paint, pour cassava corn gum into the preparation tank , while stirring, the mixture of activated clay, calcium carbonate and china clay inorganic compound is added to the preparation tank, and the resin is added to the preparation tank after 35 minutes. After mixing evenly for 30 minutes, the latex is continuously stirred at a slow speed. Ratio: 49 parts of inorganic compound mixture, 20 parts of resin, 54 parts of latex and cassava corn gum, and finally add an appropriate amount of defoamer; make color body paint, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com