Electrolytic emulsifying method for grain size controllable copper, silver and etc. ultrafine metal powder

A technology of metal powder and ultrafine powder, which is applied in the field of ultrafine metal powder materials, can solve the problems of collision probability of microemulsion particles, negative impact of nanoparticle uniformity, harm to human body and natural environment, etc., to reduce impurities and oxide content, suitable for industrial production, and resistant to storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

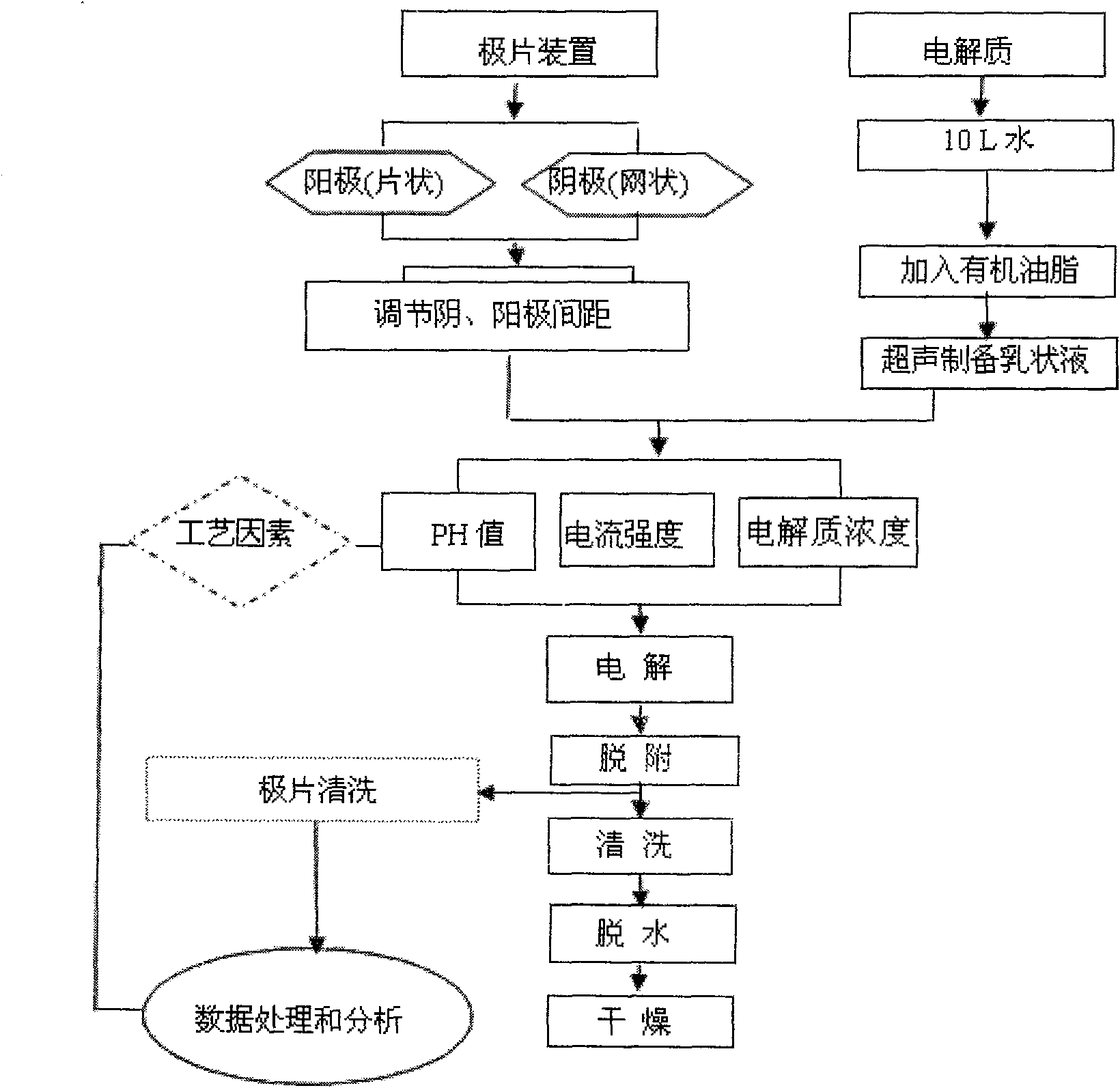

Method used

Image

Examples

example 1

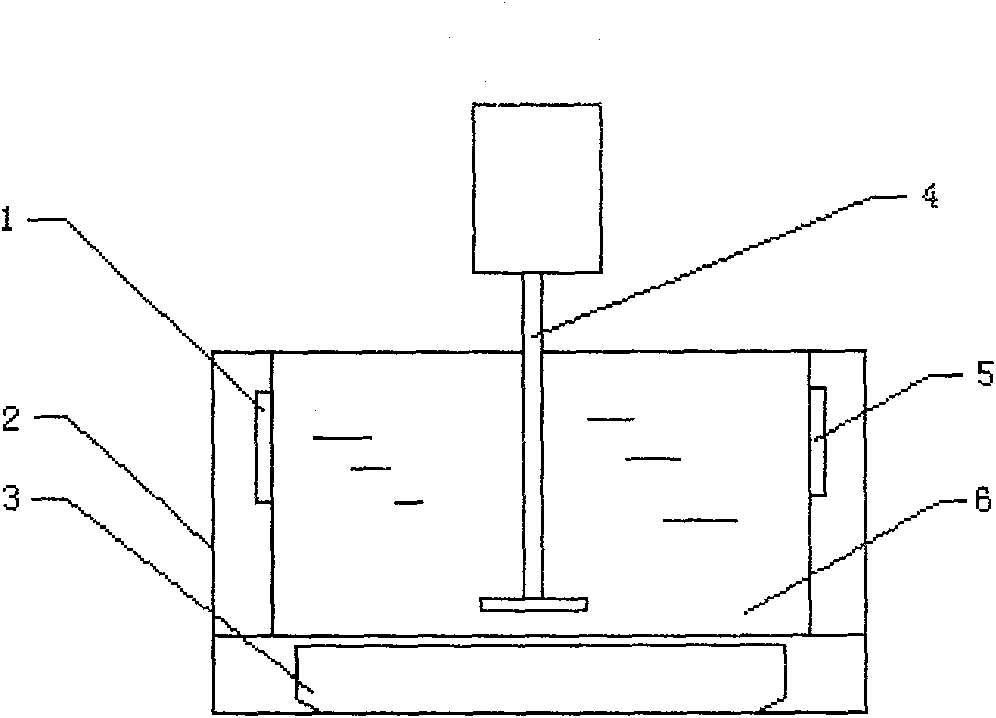

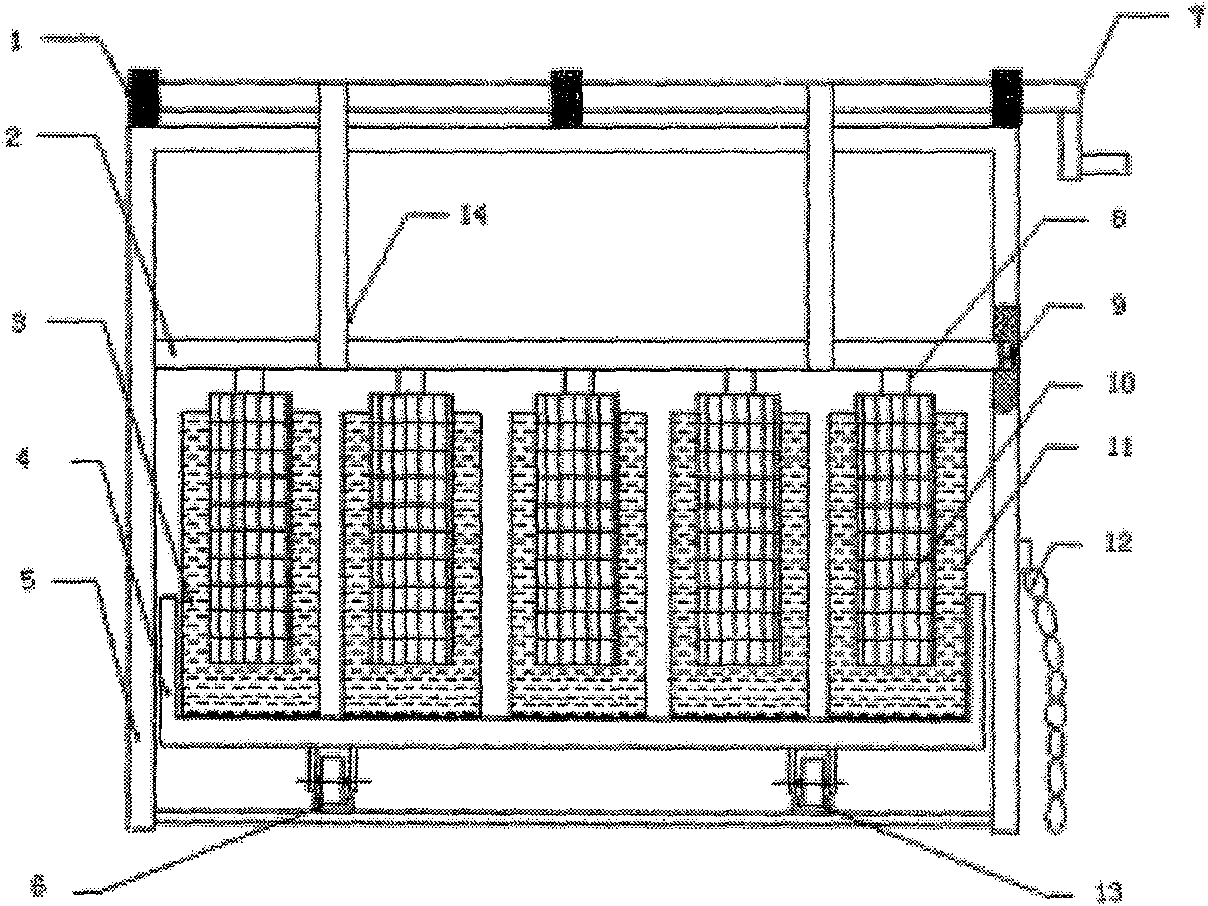

[0016] Example 1. Electrolytic emulsification method to prepare ultrafine copper powder with controllable particle size.

[0017] Weigh 160g of anhydrous copper sulfate, dissolve it in 10L of deionized water, and prepare it to a concentration of 0.1mol L -1 Inject the copper sulfate solution into the "electromagnetic stirring ultrasonic mixing tank", turn on the electromagnetic stirrer, and stir at room temperature for 10 minutes to completely dissolve the anhydrous copper sulfate in water; add 7 mL of organic oil dropwise, the introduction frequency is 60%, and the power is Use 260W ultrasonic wave to ultrasonicate the solution for 4 minutes, so that the organic oil can be fully dissolved in deionized water to form an emulsion. Utilize the "Ultrafine Powder Preparation Workstation" to make powder. Inject the prepared emulsified precursor solution into five electrolytic cells on average, adjust the pH value of each electrolytic cell to 2.0 with sulfuric acid, use pure copper ...

example 2

[0019] Example 2. The electrolytic emulsification method prepares ultra-fine silver powder with controllable particle size.

[0020] Weigh 17g of silver nitrate, dissolve it in 10L deionized water, and prepare 0.01mol L -1 Silver nitrate solution, 7mL of organic oil was added dropwise, and an emulsion was prepared in the "electromagnetic stirring ultrasonic mixing box". Inject the prepared emulsified precursor solution into the five electrolytic cells in the "Ultrafine Powder Preparation Workstation", adjust the pH value of each electrolytic cell to 3.0 with nitric acid, use pure silver as the anode and platinum as the cathode, and connect the external equipment Power supply, when the current intensity is 0.5A, the current density is about 0.15A·cm -2Under the conditions of electrolysis for 15 minutes, stop electrolysis, it can be seen that a large amount of powder is adsorbed on the surface of the cathode. Put the generated powder in ethanol (industrial grade) for desorptio...

example 3

[0022] Example 3. Preparation of superfine zinc powder with controllable particle size by electrolytic emulsification method.

[0023] Weigh 100g of zinc chloride, dissolve it in 10L deionized water, and prepare 0.1mol·L -1 Add 6mL of organic oil dropwise to the zinc chloride solution, and prepare an emulsion in the "electromagnetic stirring ultrasonic mixing box". Use the "ultrafine powder preparation workstation" to make powder, adjust the pH value of each electrolytic cell to 3.0 with hydrochloric acid, use pure zinc as the anode, and the mesh nickel-based electrode piece as the cathode, apply an external electric field, at a current intensity of 20A, Current density about 0.2A·cm -2 Under the conditions of electrolysis for 15 minutes, stop electrolysis, it can be seen that a large amount of powder is adsorbed on the surface of the cathode. Put the powder adsorbed on the surface of the cathode in ethanol (industrial grade) for desorption, rinse twice with deionized water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com