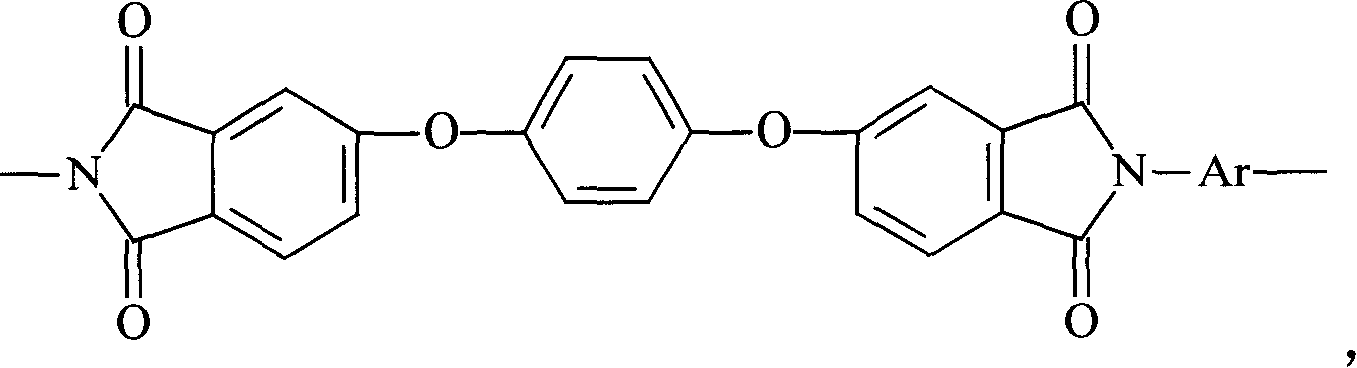

Polyimide semi-interpenetrating network resin and its prepn. method

A technology of semi-interpenetrating network and polyimide, which is applied in the field of engineering plastics, polyimide semi-interpenetrating network resin and its preparation, can solve the problem of high service temperature, achieve wide application fields, high mechanical properties, high The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

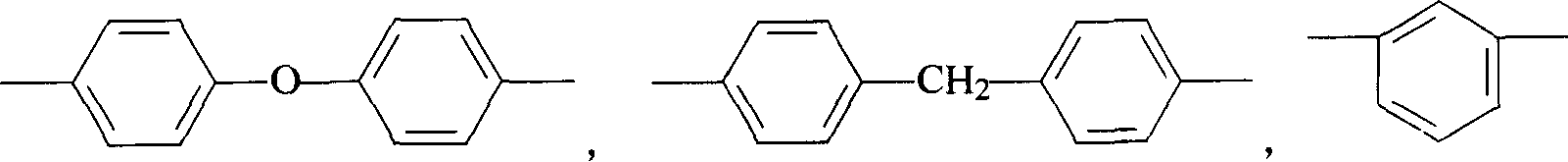

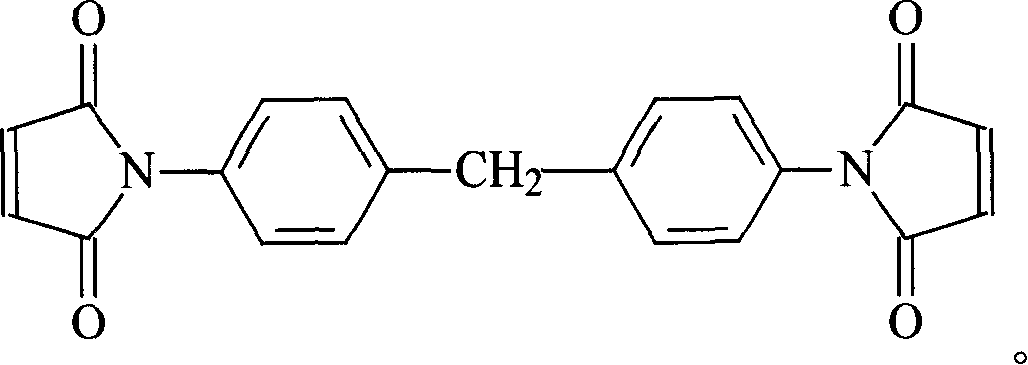

Method used

Image

Examples

Embodiment 1

[0020] Mix 70g of thermoplastic polyimide powder with 30g of bismaleimide powder and 10g of graphite in a high-speed mixer for 2min, and the resulting mixture (hereinafter referred to as the mixture) that can form a semi-interpenetrating network is packed into a mold at Press at 380° C. and 20 MPa to obtain a plate with a thickness of 5 mm.

Embodiment 2

[0022] Mix a solution of 70g thermoplastic polyimide in 600ml cresol with 30g bismaleimide powder and 10g carbon fiber at 120°C for 30min, pour it into 2000ml ethanol, wash the obtained precipitate with cold ethanol 3 times, 70 °C and dried under vacuum to obtain the mixture.

Embodiment 3

[0024] Melt 30g of bismaleimide in a constant temperature bath at 150°C, add 30g of thermoplastic polyimide and 5g of polytetrafluoroethylene powder under stirring, stir for 2 minutes, cool and pulverize to obtain a mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com