CdS/Ti-MCM-41 loaded platinum photo catalyst and its preparation method

A photocatalyst and catalyst technology, used in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of poor antioxidant capacity, increased photocorrosion, poor crystallinity, etc. The effect of improving photocorrosion ability and improving hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

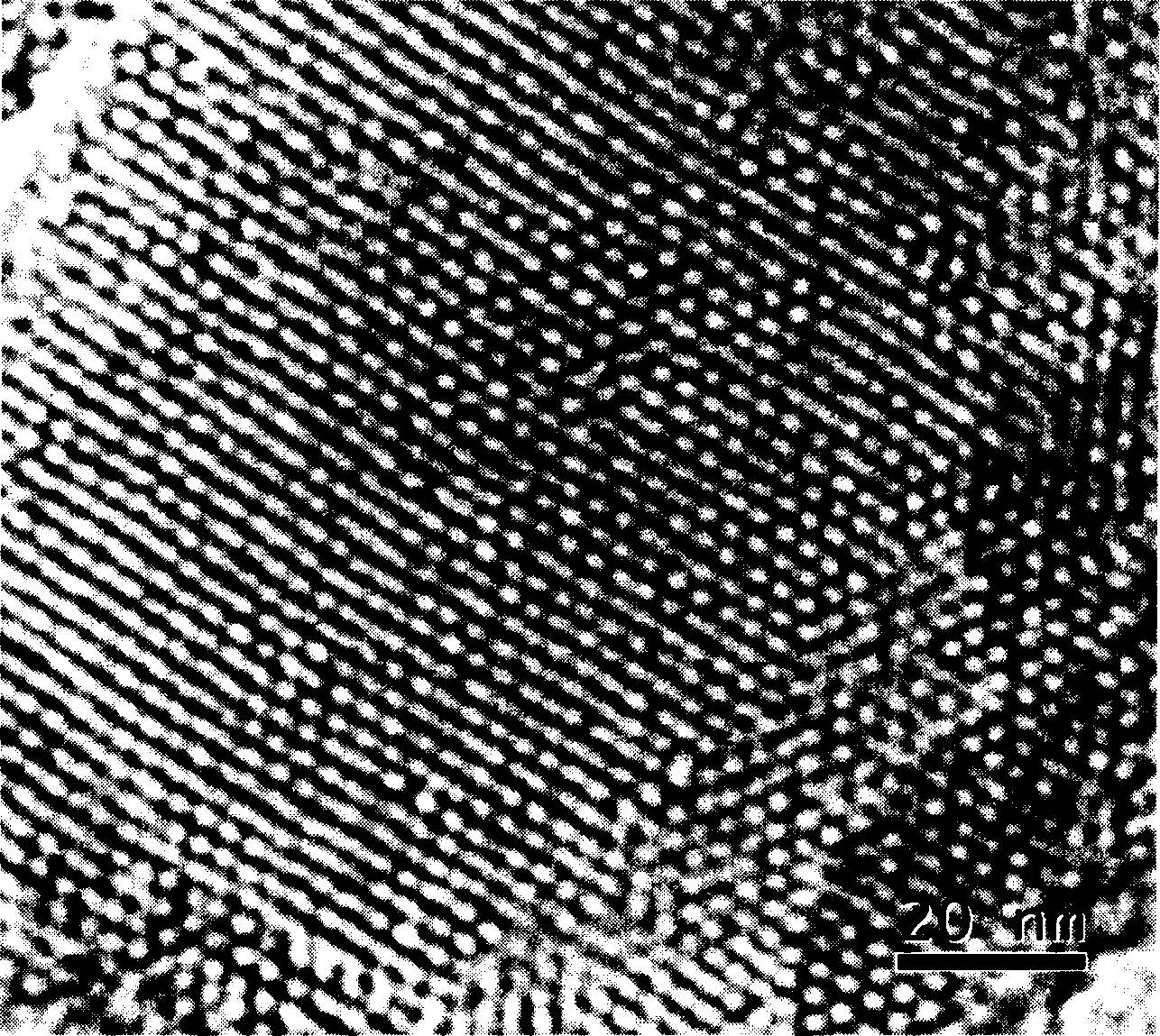

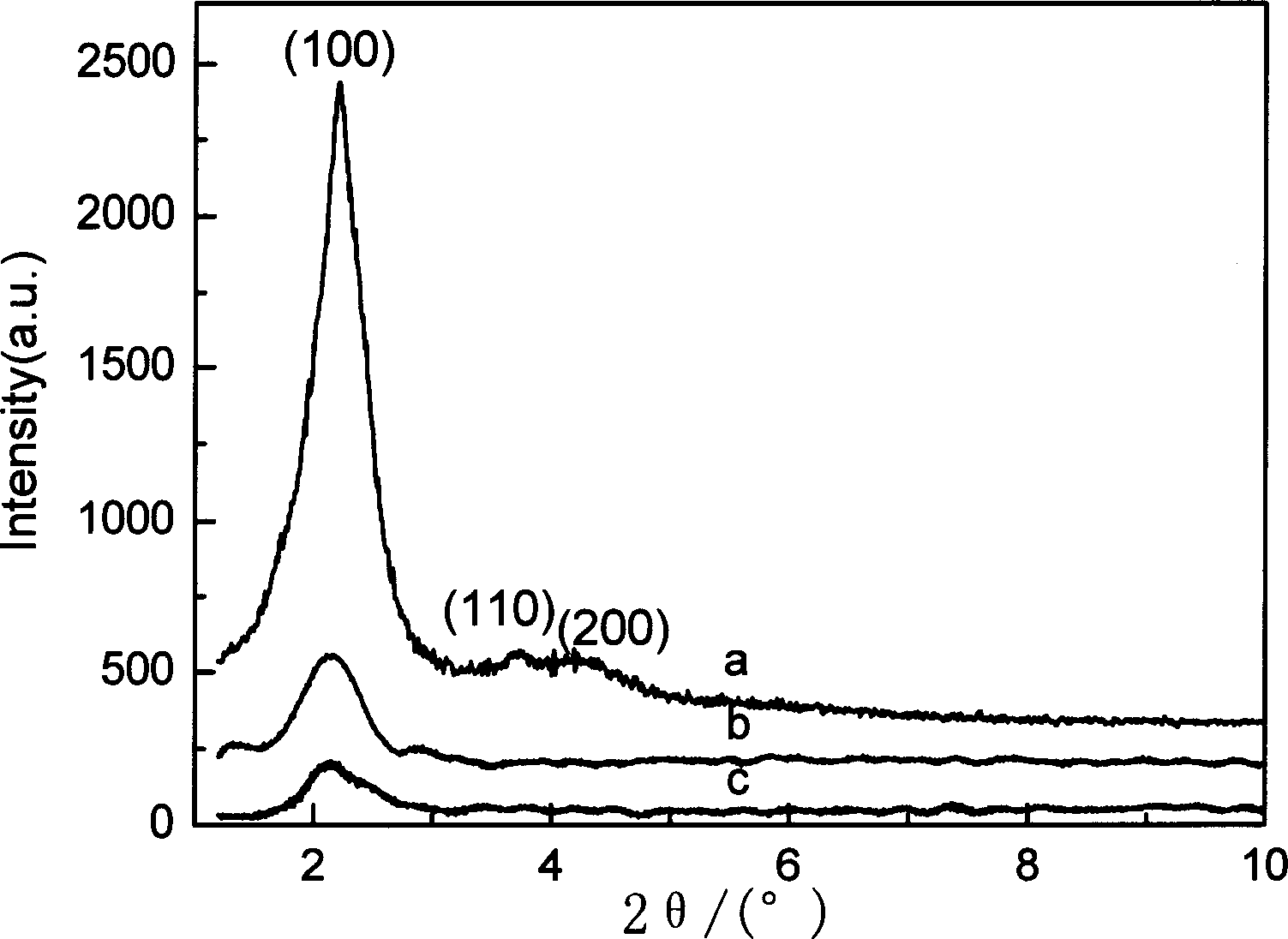

[0049] 1) In a water bath at 40°C, dissolve 0.36g of sodium hydroxide NaOH and 1.82g of cetyltrimethylammonium bromide CTAB in 45mL of deionized water, and slowly drop into 8.21mL of tetraethylorthosilicate with a pipette Ester TEOS, stirred at a speed of 800rpm to facilitate the hydrolysis of TEOS; 0.25g of tetrabutyl titanate TBOT was added dropwise after 0.5h, and the solution was transferred to a hydrothermal kettle with a Teflon liner after continuing to stir for 1h. Crystallized at 100°C for 72h. After the hydrothermal kettle was lowered to room temperature, the solution was filtered, repeatedly washed with deionized water and dried to obtain white raw powder CTAB / Ti-MCM-41;

[0050] 2) Calcining 2g of white raw powder CTAB / Ti-MCM-41 in air atmosphere at 500°C for 10h to remove template agent CTAB to obtain mesoporous matrix Ti-MCM-41;

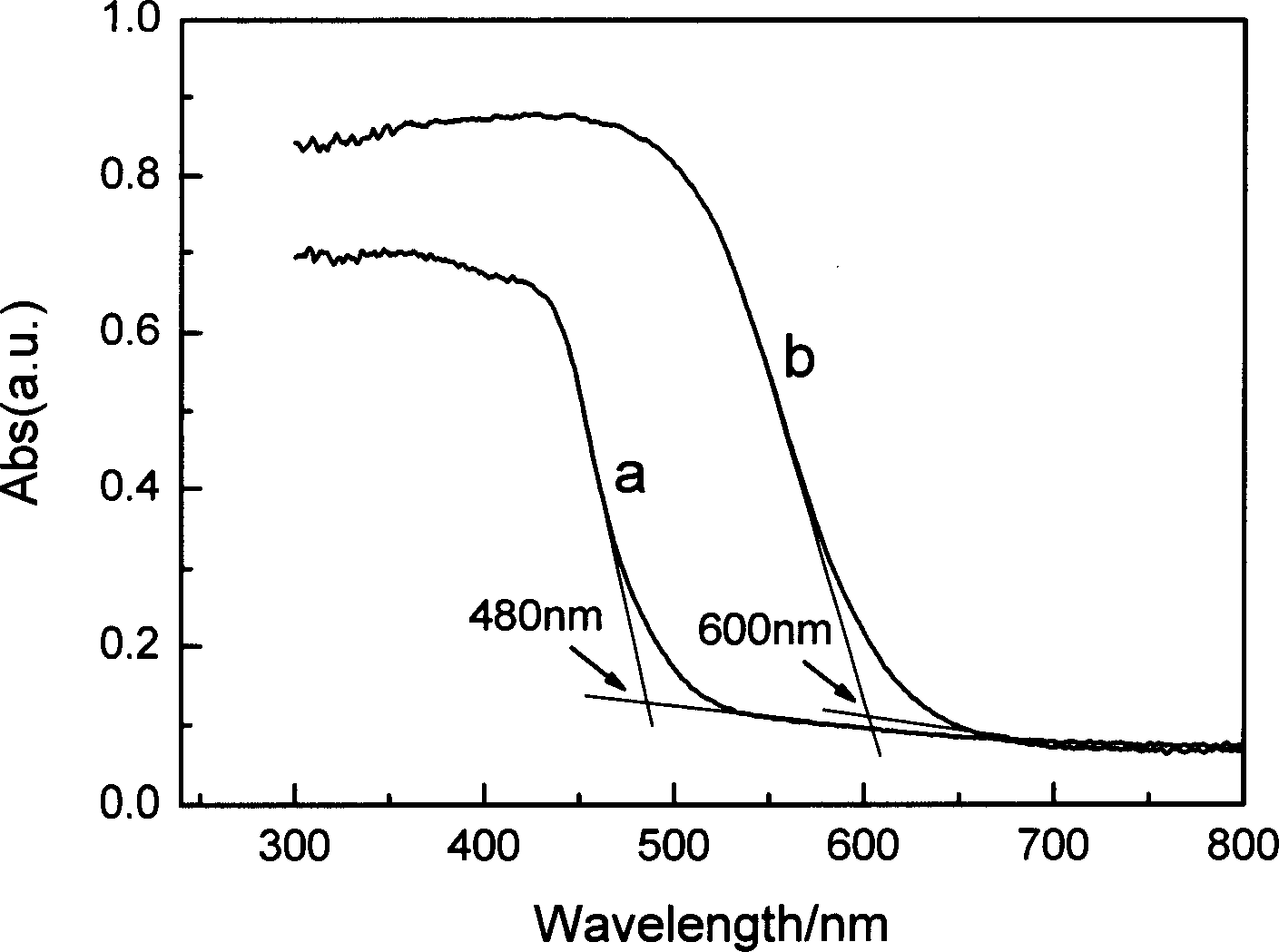

[0051] 3) 1.25g cadmium acetate CdAc 2 Dissolve in 100mL methanol MeOH, add 1.0g CTAB / Ti-MCM-41 raw powder, and reflux at the boiling...

Embodiment 2

[0061] 1) In a water bath at 60°C, dissolve 0.72g of sodium hydroxide NaOH and 3.64g of cetyltrimethylammonium bromide CTAB in 90mL of deionized water, and slowly drop into 16.4mL of tetraethylorthosilicate with a pipette Ester TEOS, stirred at a speed of 500rpm to facilitate the hydrolysis of TEOS; 0.25g of tetrabutyl titanate TBOT was added dropwise after 1h, and after stirring for 1h, the solution was transferred to a hydrothermal kettle with a polytetrafluoroethylene liner and placed in Crystallized at 100°C for 72h. After the hydrothermal kettle was lowered to room temperature, the solution was filtered, repeatedly washed with deionized water and dried to obtain white raw powder CTAB / Ti-MCM-41;

[0062] 2) Calcining 2g of white raw powder CTAB / Ti-MCM-41 in air atmosphere at 500°C for 5h to remove template agent CTAB to obtain mesoporous matrix Ti-MCM-41;

[0063] 3) 1.25g cadmium acetate CdAc 2 Dissolve in 100mL methanol MeOH, add 1.0g CTAB / Ti-MCM-41 raw powder, and ref...

Embodiment 3

[0073] 1) In a water bath at 40°C, dissolve 0.72g of sodium hydroxide NaOH and 3.64g of cetyltrimethylammonium bromide CTAB in 90mL of deionized water, and slowly drop into 16.4mL of tetraethylorthosilicate with a pipette Ester TEOS, stirred at a speed of 800rpm to facilitate the hydrolysis of TEOS; 0.25g of tetrabutyl titanate TBOT was added dropwise after 1h, and after stirring for 1h, the solution was transferred to a hydrothermal kettle with a polytetrafluoroethylene liner and placed in Crystallized at 110°C for 48h. After the hydrothermal kettle was lowered to room temperature, the solution was filtered, repeatedly washed with deionized water and dried to obtain white raw powder CTAB / Ti-MCM-41;

[0074]2) Calcining 2g of white raw powder CTAB / Ti-MCM-41 in air atmosphere at 600°C for 5h to remove template agent CTAB to obtain mesoporous matrix Ti-MCM-41;

[0075] 3) 2.5g cadmium acetate CdAc 2 Dissolve in 200mL methanol MeOH, add 2.0g CTAB / Ti-MCM-41 raw powder, and reflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com