Surface activator with double-ether bisbensulfosalt and double molecule

A bisbenzenesulfonate and surfactant technology, applied in the field of anionic sulfonate surfactant and its preparation, can solve the problem that the performance of the surfactant cannot meet the engineering requirements, it is easy to be adsorbed by the clay surface, and it is difficult to achieve ultra-low Surface tension and other problems, to achieve the effect of excellent surface activity, cheap raw materials, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The synthesis of embodiment 1 DEDS-10

[0042] Add 4.5658g (0.02mol) of bisphenol A and 17.6g (containing NaOH0.044mol) of bisphenol A into a 250ml three-necked flask equipped with a stirrer and a thermometer, fully react at 50-70°C for 30min, and then add 60ml of Add 10.1798 g (0.046 mol) of decanyl bromide to water and ethanol, and react in a constant temperature water bath at 70°C for 24 hours. After the reaction was completed, the absolute ethanol was evaporated, the product was washed twice with water, then left to separate the liquids, and the upper layer solid was recrystallized with a mixed solvent of ethyl acetate and acetone to obtain white crystals, which were 2,2-bis(4-deca alkoxyphenyl)-propane. The lower liquid uses AgNO 3 After titration, the yield of 2,2-bis(4-decyloxyphenyl)-propane was 98.5%, and the crystallization melting point was 35.7-36.1°C.

[0043]Take 5.1029g (0.01mol) of 2,2-bis(4-decyloxyphenyl)-propane into a three-necked flask, dissolve ...

Embodiment 2

[0044] The synthesis of embodiment 2 DEDS-12

[0045] Add 4.5658g (0.02mol) of bisphenol A and 17.6g (containing NaOH0.044mol) of bisphenol A into a 250ml three-necked flask equipped with a stirrer and a thermometer, fully react at 50-70°C for 30min, and then add 60ml of Add 11.4678 g (0.046 mol) of dodecyl bromide to water and ethanol, and react in a constant temperature water bath at 60°C for 24 hours. After the reaction was completed, the absolute ethanol was evaporated, the product was washed twice with water, then left to separate the liquids, and the upper layer solid was recrystallized with a mixed solvent of ethyl acetate and acetone to obtain white crystals, which were 2,2-bis(4-deca dialkoxyphenyl)-propane. The lower liquid uses AgNO 3 Titration was carried out, and the yield of 2,2-di(4-dodecyloxyphenyl)-propane was measured to be 89.3%, and the crystallization melting point was 45.7-46.4°C.

[0046] Take 5.6629g (0.01mol) of 2,2-bis(4-dodecyloxyphenyl)-propane i...

Embodiment 3

[0047] The surface activity measurement of embodiment 3 DEDS series surfactants

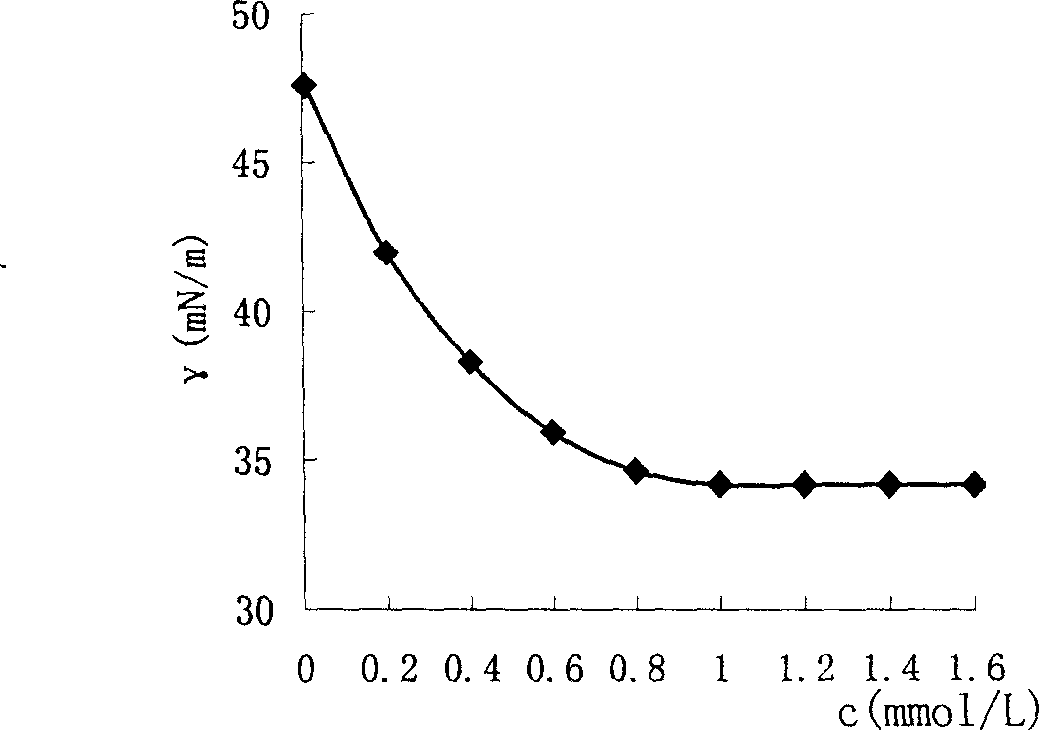

[0048] Prepare the DEDS-10 aqueous solution of concentration 1.6mmol / L, measure surface tension with JZhy1-180 interfacial tensiometer, then dilute this solution successively, measure surface tension several times every dilution, obtain the relation of DEDS-10 aqueous solution surface tension and concentration ( See figure 1 ). Depend on figure 1 The surface tension (γcmc) at the critical micelle concentration of DEDS-10 can be found to be 34.5mN / m, and its critical micelle concentration is 0.47mmol / L. Compared with ordinary surfactants, its surface activity is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal melting point | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com