Wet-method etching liquid for making phase change storage and its wet-method etching process

A technology of wet etching and storage, which is applied in the field of microelectronics technology, and can solve problems such as high cost and complex manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Configure 50 grams of wet etchant:

[0031] Take 10 grams of hydrochloric acid solution, add 3 grams of 30% H 2 o 2 solution, add 1 gram of ethylenediaminetetraacetic acid (EDTA), 0.5 gram of fatty alcohol polyoxyethylene ether (JFC), and add deionized water to the rest.

[0032] (2) Prepare samples for wet etching:

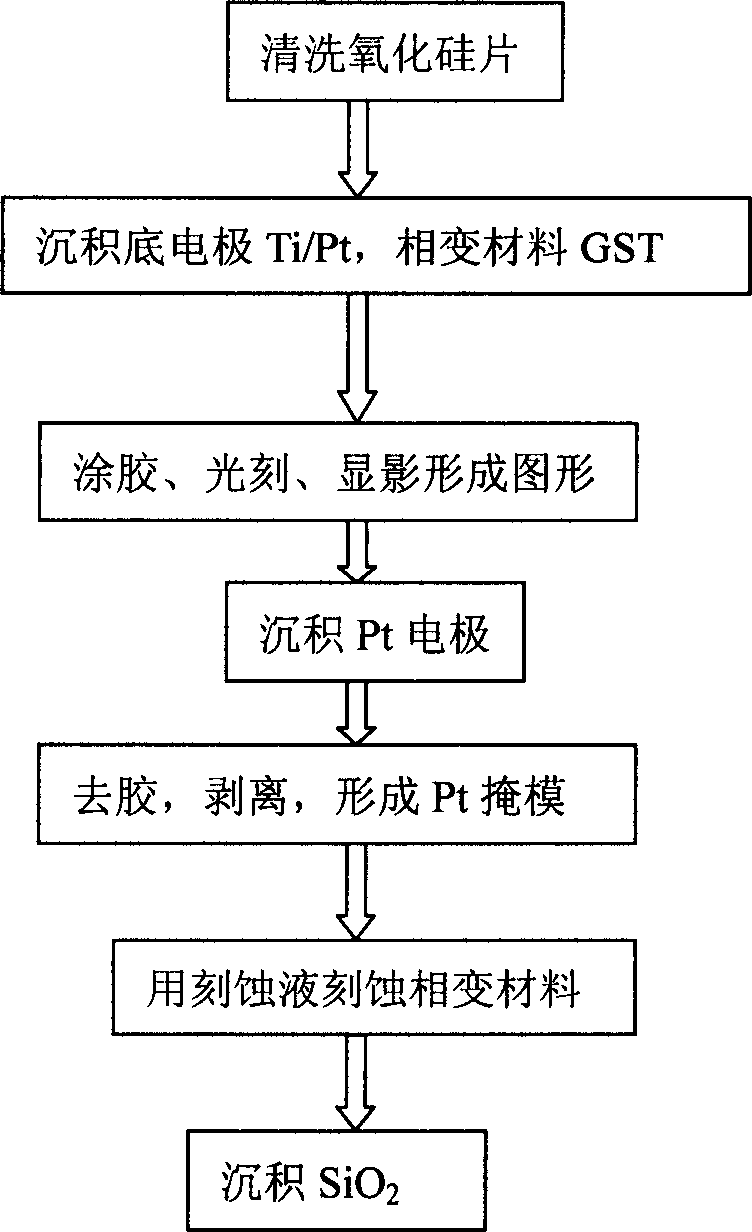

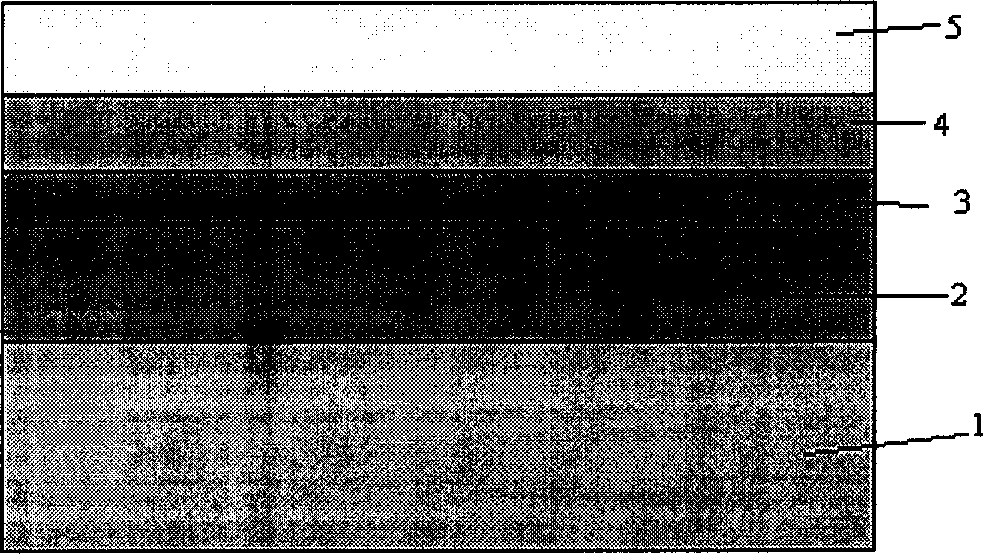

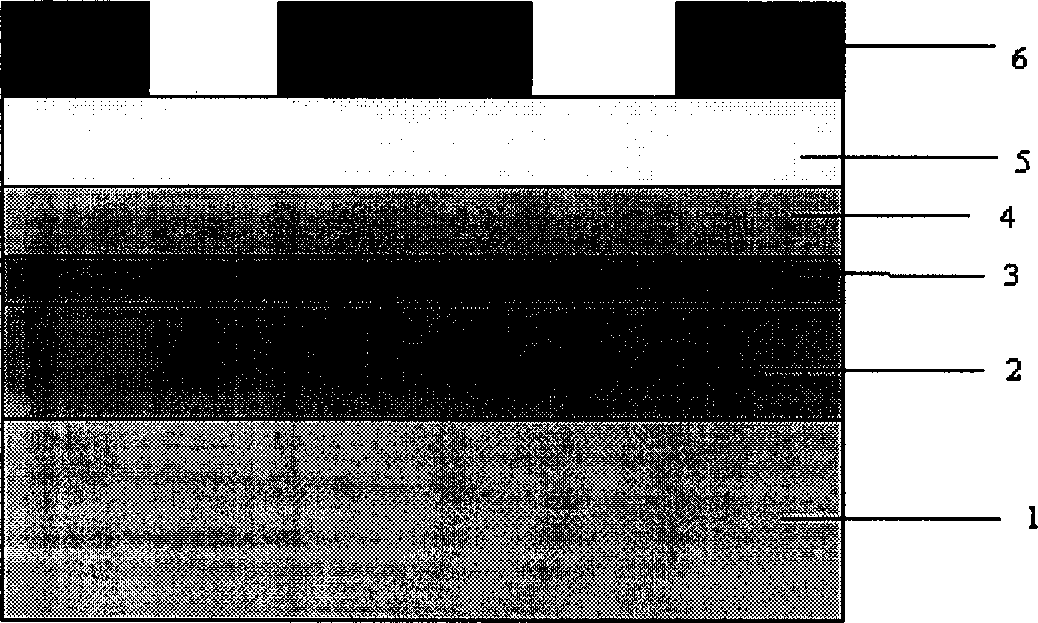

[0033] The silicon oxide wafer is ultrasonically cleaned with acetone, cleaned in the cleaning solution of ammonia water plus hydrogen peroxide, hydrochloric acid plus hydrogen peroxide, respectively, and blown dry with nitrogen after cleaning. Sputter a 30nm metal thin film Ti on a clean silicon oxide wafer with a magnetron sputtering table, then sputter a 100nm metal thin film Pt as the bottom electrode, and finally sputter a 200nm phase change material Ge 2 Sb 2 Te 5 . Coat the sputtered sample with photoresist, place it in a constant temperature box for 35 minutes, then expose it with a photolithography machine for 7 seconds, soak it in chlor...

Embodiment 2

[0038] (1) Configure 50 grams of etchant

[0039] Take 10 grams of tartaric acid, dissolve it in 30 grams of deionized water, add 1 gram of H 2 o 2 , add 1 gram of ethylenediaminetetraacetic acid (EDTA), add 1 gram of fatty alcohol polyoxyethylene ether (JFC), and add deionized water to the rest.

[0040] (2) Prepare etching samples.

[0041] Ultrasonic the silicon oxide sheet with acetone, wash it in ammonia water plus hydrogen peroxide, hydrochloric acid plus hydrogen peroxide cleaning solution, respectively, and dry it with nitrogen after cleaning. Sputter a 50nm metal thin film Ti on a clean silicon oxide wafer with a magnetron sputtering table, then sputter a 100nm metal thin film Pt as the bottom electrode, and finally sputter a 300nm phase change material Ge 2 Sb 2 Te 5 . Coat the sputtered sample with photoresist, place it in a constant temperature box for 30 minutes, then expose it with a photolithography machine for 7 seconds, soak it in chlorobenzene for 5 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com