High temperature alloy product material regenerative cycle utilizing method

A high-temperature alloy and product technology, applied in the field of high-temperature alloy product material regeneration and recycling, can solve the problems of waste material depreciation, high use cost, waste of resources, etc., achieve the effects of reducing oxygen index, improving firing performance, and improving creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

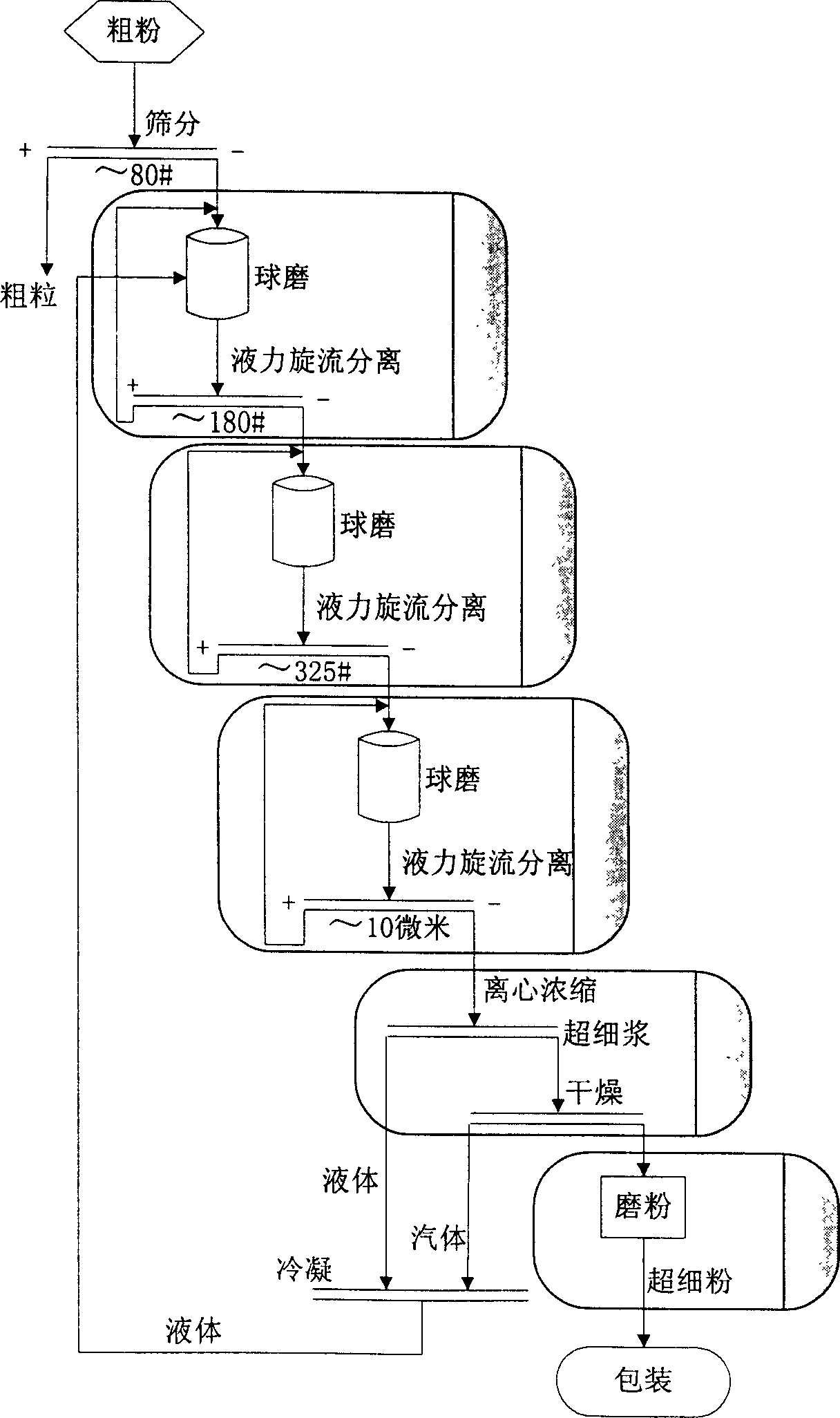

[0023] Such as figure 1 , image 3 As shown, the difference between this example and Example 1 is that the granulation in this example adopts the pre-alloying atomization method for granulation, that is, pre-alloying is remelted first, and then atomization is used to make powder. The ultra-fine powder can be produced by circulating swirling ball milling process, that is, the coarse powder is first sieved by 80#, then separated by 180# ball mill hydrocyclone, and then separated by 325# ball mill hydrocyclone to obtain 10 microns The powder is then centrifugally concentrated, dried and pulverized to obtain superfine powder, and the particle size of the superfine powder is less than or equal to 10 microns. The invention adopts the mixed liquid of oil and alcohol as the hydraulic medium of the circulating swirl ball milling production process, which can not only reduce the oxidation degree of superfine superalloy powder, but also promote the separation effect of the circulating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com