Method for preparing 4,4'-diaminodiphenyl ether

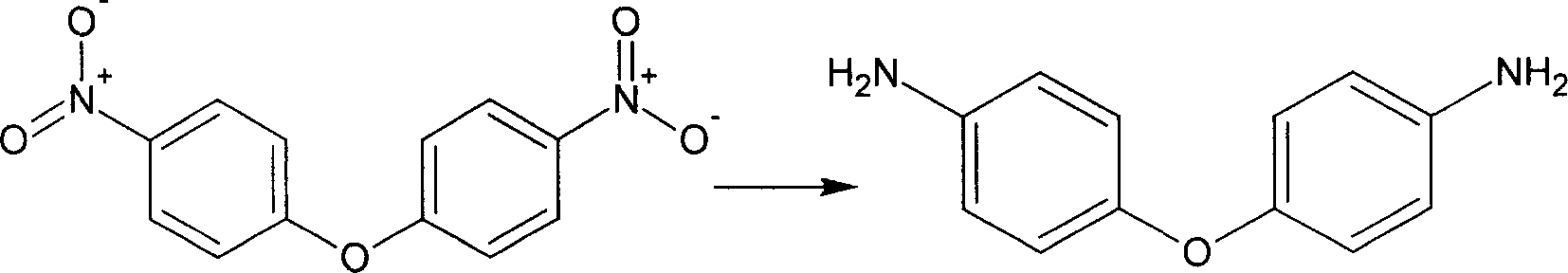

A technology of diaminodiphenyl ether and dinitrodiphenyl ether, applied in the field of preparation 4, can solve the problems of high price, strong corrosion and high cost of hydrazine hydrate, and achieve easy industrial promotion and application, good quality and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

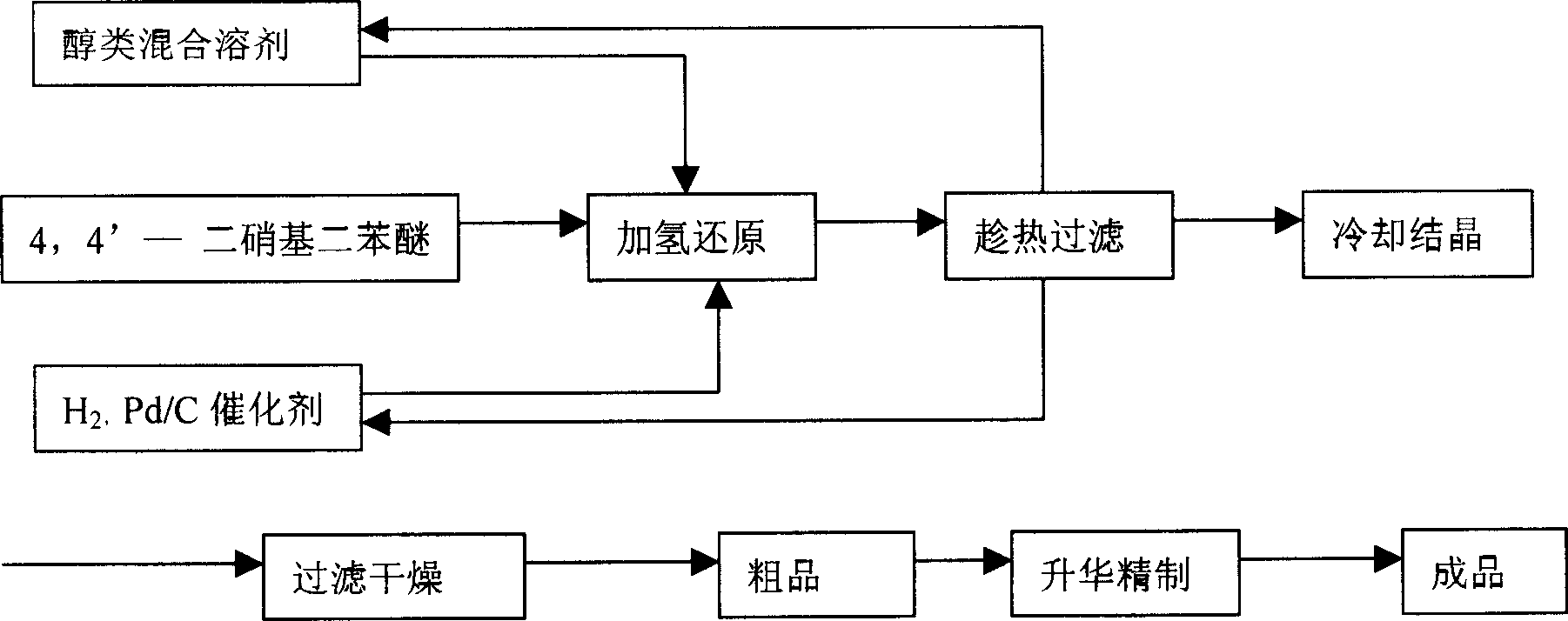

Method used

Image

Examples

Embodiment 1

[0024] Into the autoclave of 50L band stirrer, drop into 4Kg 4,4'-dinitrodiphenyl ether, 20g Pd content is the mixed solvent that the Pd / c catalyst of 3%, 25L methyl alcohol and 5L dimethylformamide form, Steam is passed into the interlayer of the high-pressure reactor to heat up the temperature. The high-pressure reactor is first replaced with nitrogen three times, and then replaced with hydrogen three times respectively, and the catalytic hydrogenation reduction reaction is carried out under the conditions of 95-100°C and 0.4Mpa. After the hydrogenation reaction is completed, filter while it is hot to separate the Pd / C catalyst, and then recycle the separated Pd / C catalyst after cleaning and activation. The crude 4,4'-diaminodiphenyl ether is 2.78Kg, the melting point is 190.0~190.4℃, the molar yield is 90.4%, the mixed solvent can also be recycled, and the crude 4,4'-diaminodiphenyl ether is vacuum sublimated 2.77 kg of white crystals of polymer grade 4,4'-diaminodiphenyl e...

Embodiment 2

[0026] Other conditions are the same as in Example 1, except that the Pd / c catalyst adopts a Pd / c catalyst with a Pd content of 5%. 2.83Kg of crude 4,4'-diaminodiphenyl ether was obtained, with a melting point of 190.1-190.5°C and a molar yield of 91.8%. The crude 4,4'-diaminodiphenyl ether was sublimated under reduced pressure to obtain 2.80 kg of white crystals of polymerization-grade crude 4,4'-diaminodiphenyl ether, with a melting point of 191.0-191.5°C and a molar yield of 91.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com