Chemical vapor deposition film formed by plasma cvd process and method for forming same

A plasma and evaporation film technology, applied in gaseous chemical plating, devices and containers for coating liquid on surfaces, etc., can solve the problems of reduced gas isolation and high moisture permeability

Inactive Publication Date: 2010-09-08

TOYO SEIKAN KAISHA LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Furthermore, although the traditional evaporated film formed according to the above-mentioned method has excellent barrier properties to various gases (such as oxygen), due to its high moisture permeability, moisture can penetrate into the evaporated film, thereby reducing its gas barrier properties. This is also its shortcoming, especially in the field of packaging materials, people are asking for improvement of this performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

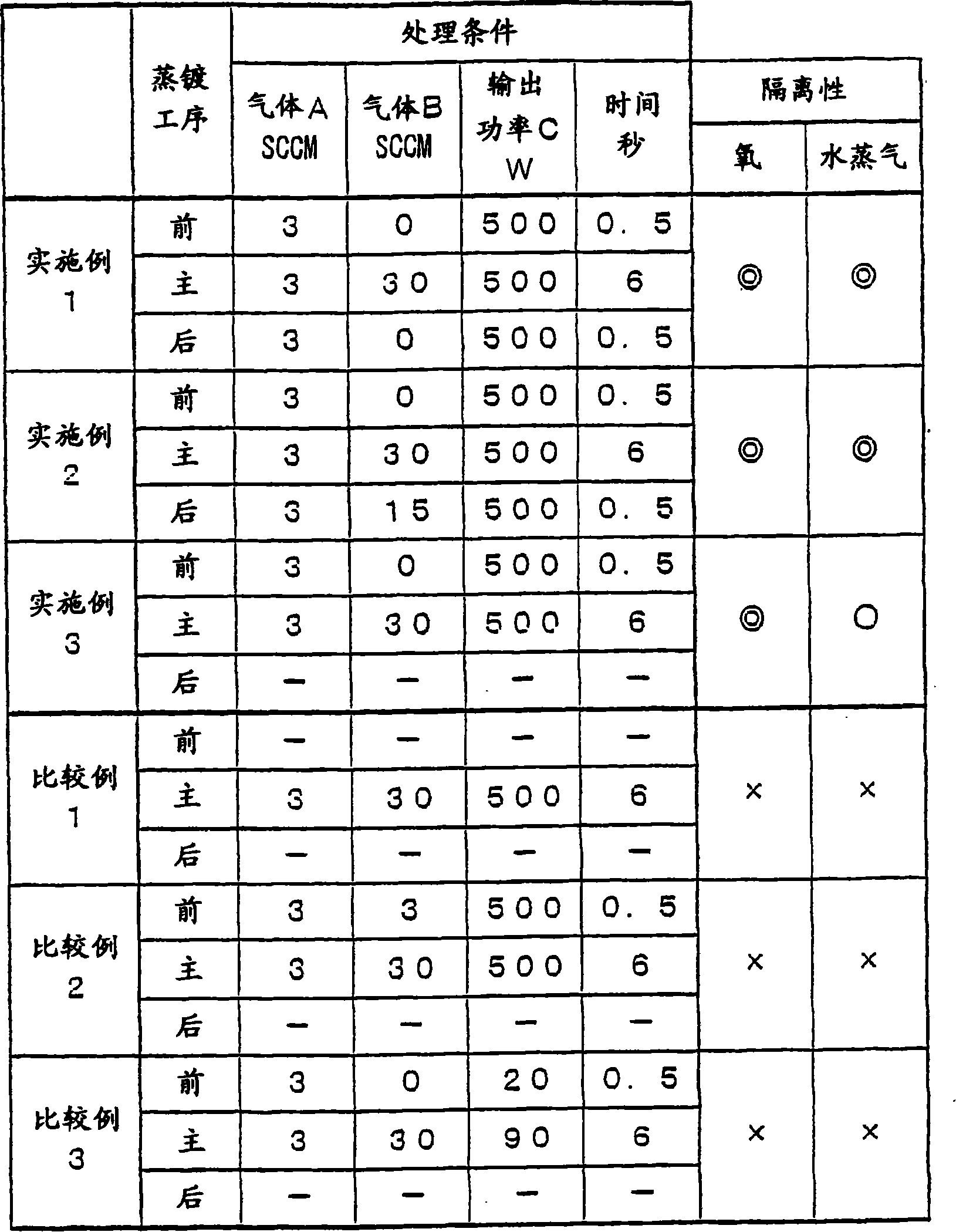

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

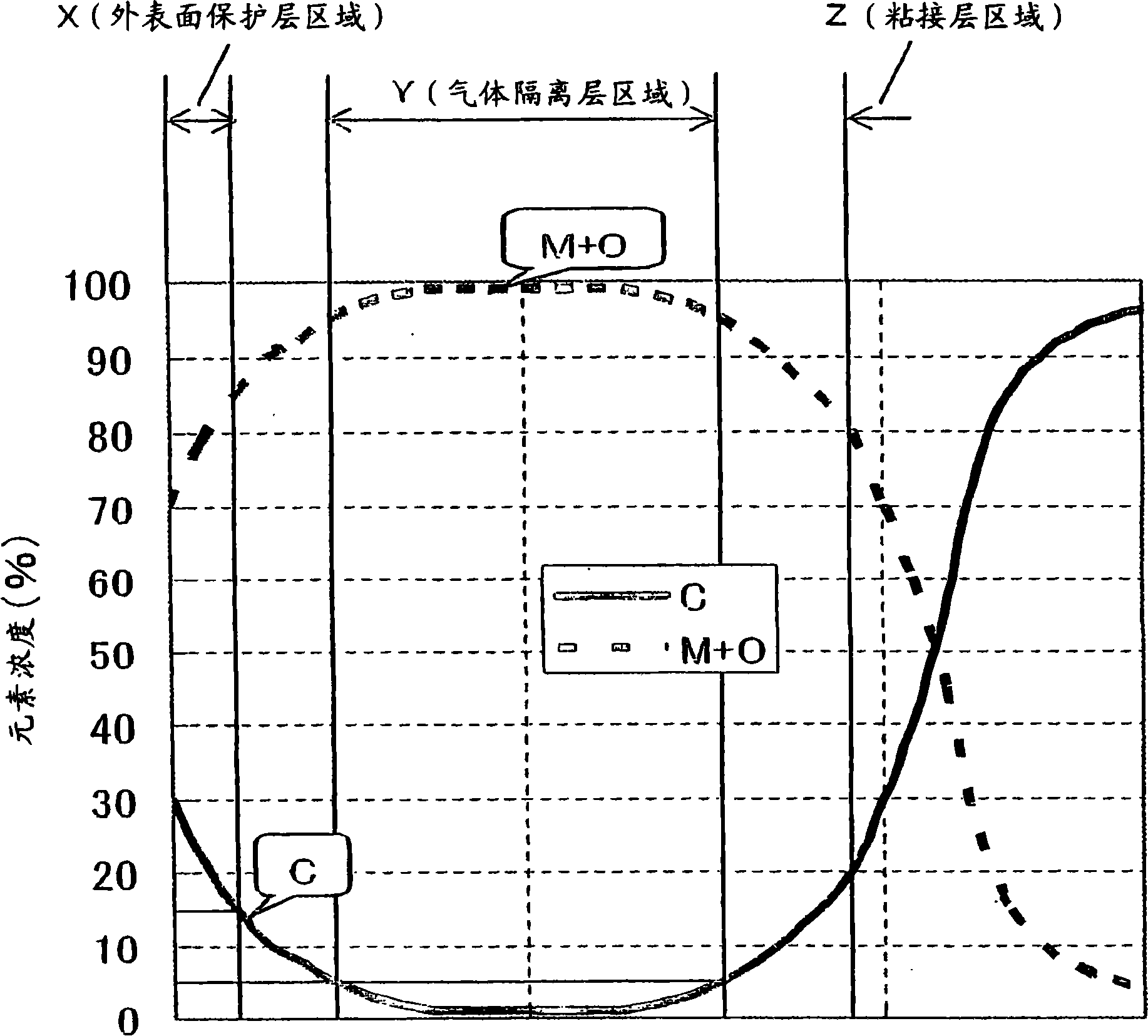

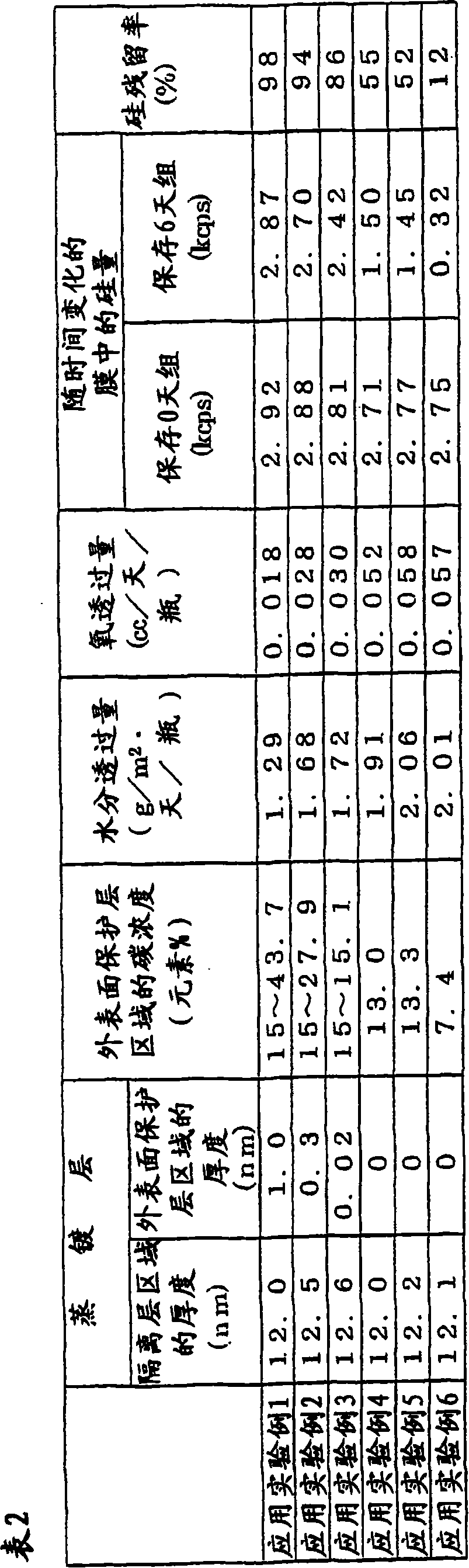

A method for forming a vapor deposition film is composed of a silicon oxide on a surface of a substrate is disclosed in which the substrate to be processed is held in a plasma processing chamber and a chemical plasma processing is conducted by supplying an organic silicon compound and an oxidizing gas into the processing chamber. By changing the supply rate of the oxidizing gas during formation of a deposition film while keeping the supply rate of the organic silicon compound gas at a certain fixed rate, there can be formed a chemical vapor deposition film which is excellent in adhesion, plasticity, flexibility, oxygen barrier property and moisture barrier property.

Description

technical field The present invention relates to a method of forming a vapor-deposited film containing a metal oxide such as silicon oxide on the surface of a substrate such as a plastic substrate by a plasma CVD method, and to a vapor-deposited film formed by the method. Background technique Chemical vapor deposition (CVD) is a technology that uses a raw material gas that does not react at room temperature to deposit a film-like reaction product on the surface of the substrate through vapor phase growth in a high-temperature atmosphere. Technologies widely used in the manufacture of semiconductors, the modification of metal or ceramic surfaces, etc., are recently being used for surface modification of plastic containers, especially for improving gas barrier properties. Plasma CVD is a technique of using plasma to grow thin films, which basically includes the following steps, that is, under reduced pressure, using electric energy formed by a strong electric field to dischar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C16/40B65D1/00B65D23/02B05D3/10C08J7/04C23C16/42

Inventor 小林亮并木恒久细野宽子仓岛秀夫稻垣肇家木敏秀

Owner TOYO SEIKAN KAISHA LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com