Process for growing lanthanum chloride crystal by falling method of antivacuum crucible

A crucible descending method and lanthanum chloride technology are used in the non-vacuum crucible descending method to grow lanthanum chloride crystals, the preparation of pure lanthanum chloride and cerium-doped lanthanum chloride crystals, and the platinum crucible descending method to grow high-quality lanthanum chloride and lanthanum chloride crystals. In the field of cerium-doped lanthanum chloride crystals, it can solve the problems of growth failure, crystal devitrification and scintillation performance, and quartz crucible bursting, and achieve the effect of low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

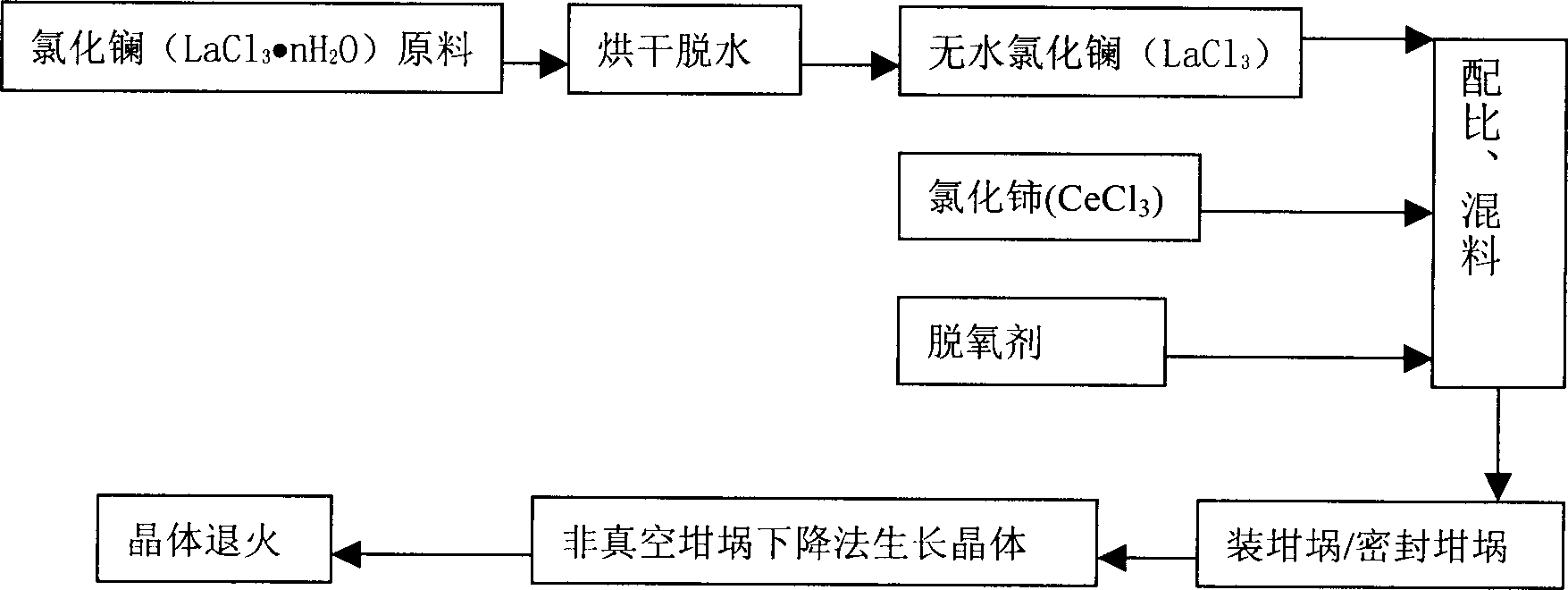

[0019] Grow LaCl 3 The specific process steps of the crystal are:

[0020] (1) With high-purity LaCl 3 ·nH 2 O (n = 3 ~ 7) as raw material, in an inert flow atmosphere (N 2 or Ar gas) or suppressed flow atmosphere (HCl), according to the differential thermal analysis results of raw materials, first remove the adsorbed water at a temperature of 120 ° C, and then increase the temperature at 150 ° C, 180 ° C, 220 ° C and 250 ° C respectively At a temperature of ℃, the water of crystallization is removed, dried, and dried in stages;

[0021] (2) select carbon tetrachloride to be deoxidizer, mix with the powder material after step (1) process, and add-on is 800ppm;

[0022] (3) LaCl of φ25×200mm 3 The grain crystal is placed in the bottom of the crucible made of rectangular columnar iridium, and then the raw materials of the above step (2) are put in, and the crucible is sealed; the wall thickness of the crucible is 0.20mm;

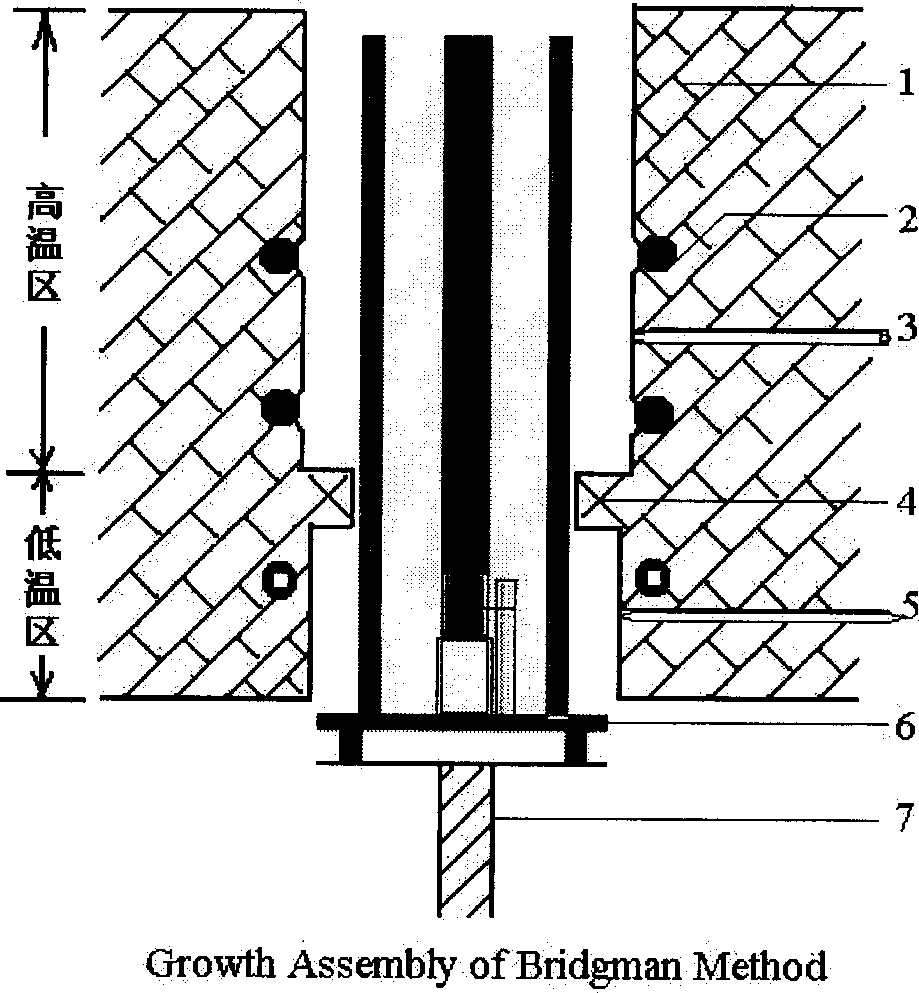

[0023] (4) Four straight silicon-molybdenum rods a...

Embodiment 2

[0028] (1) High-purity LaCl 3 ·nH 2 0 (n = 3 ~ 7) as raw material, in an inert flow atmosphere (N 2 or Ar gas) or suppressed flow atmosphere (HCl), according to the differential thermal analysis results of raw materials, first remove the adsorbed water at a temperature of 120 ° C, and then increase the temperature at 150 ° C, 180 ° C, 220 ° C and 250 ° C respectively At a temperature of ℃, the water of crystallization is removed, dried, and dried in stages;

[0029] (2) High-purity cerium chloride (CeCl) used as a luminescent activator 3 ) also needs to be dried in an oven at a temperature not lower than 120°C for 4-6 hours before being incorporated into the main raw material. Then follow the equivalent LaCl 3 The molar ratio is 10% and the ingredients are fully mixed evenly;

[0030] (3) Platinum material is selected and processed into a cylindrical crucible of φ25×200mm, with a wall thickness of 0.12mm, sealed with argon gas, and tested for airtight leaks to ensure that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com