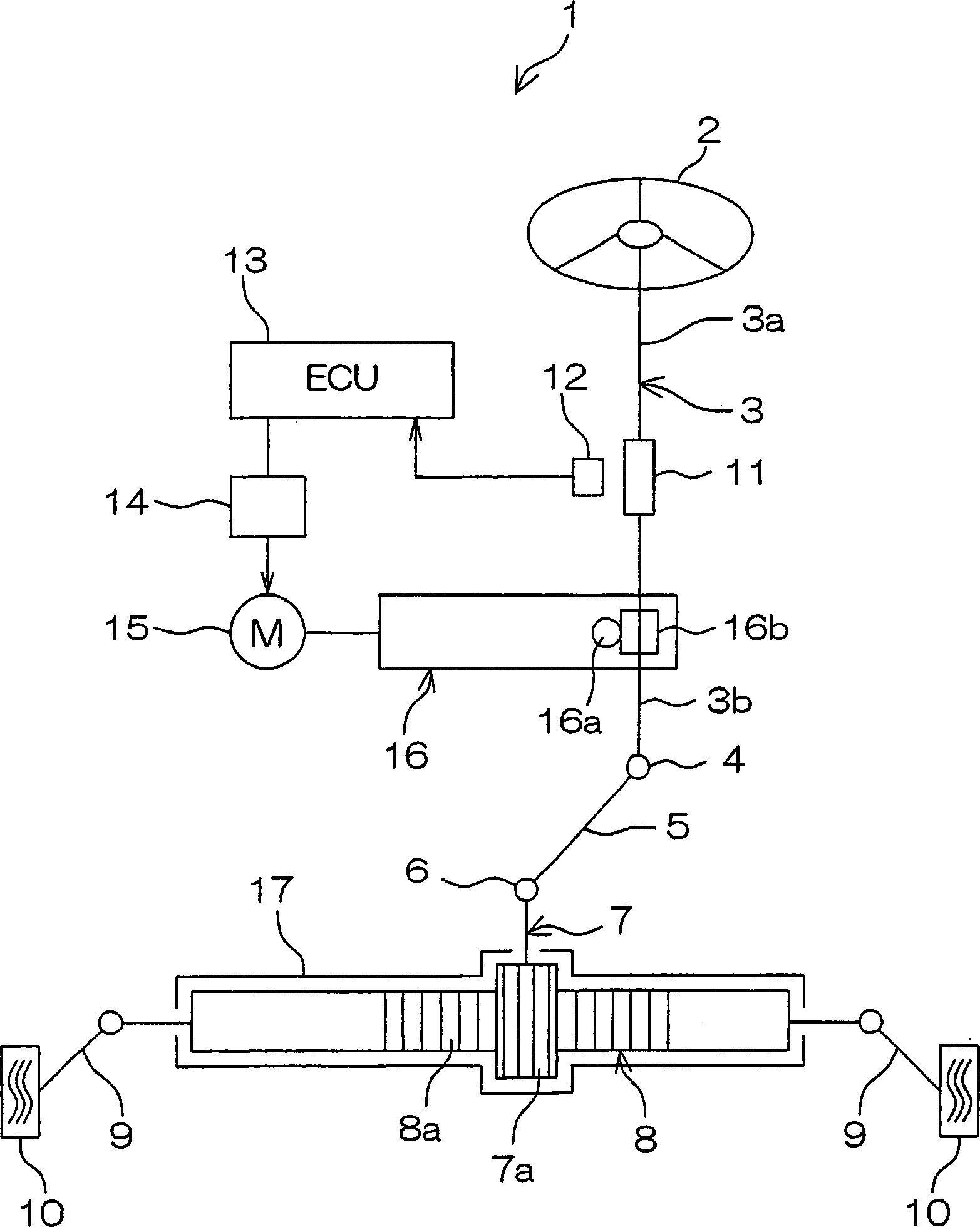

Steel bar for steering rack, method for producing the same, and steering rack using the same

A technology for steering racks and manufacturing methods, applied in the direction of manufacturing tools, mechanical steering gears, furnace types, etc., can solve problems such as fracture, insufficient wear resistance, expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1~36

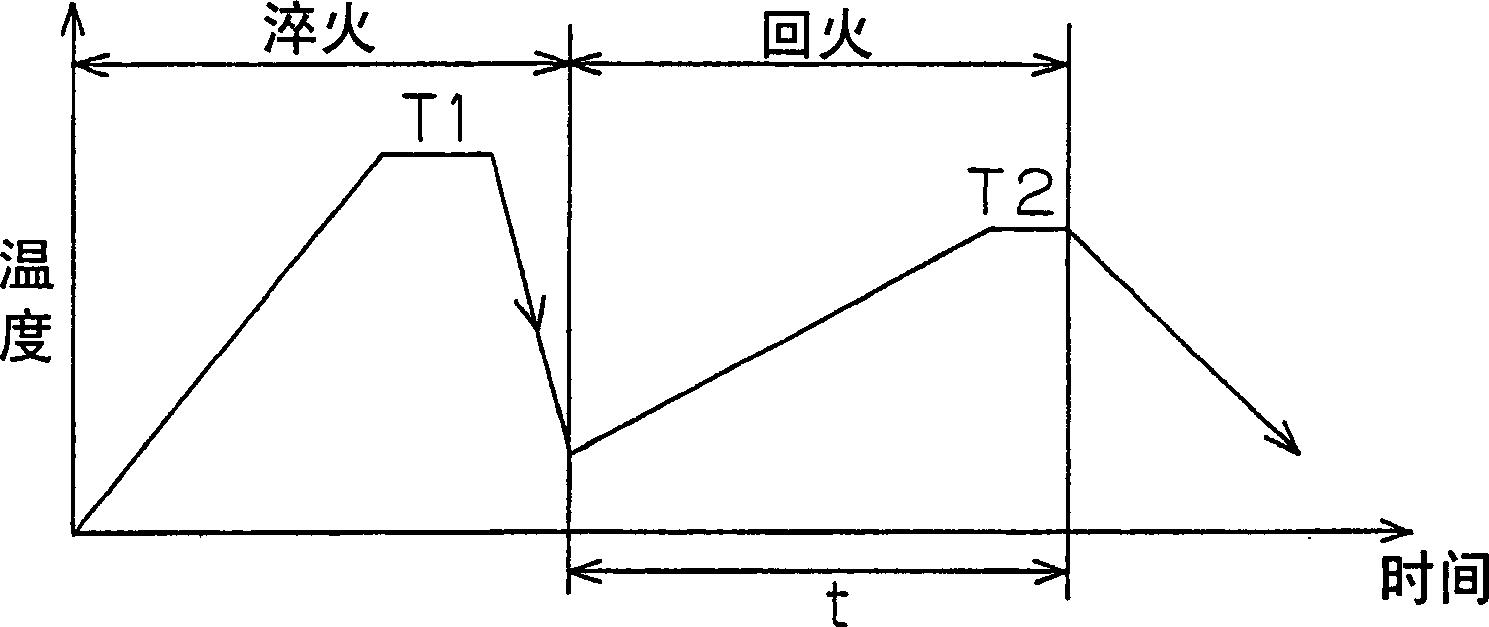

[0064] Steel materials having the compositions shown in Tables 1 to 2 below were melted and rolled into steel bars with a diameter of 30 mm. Then, after heating to the temperature shown in Tables 1-2, quenching was completed by controlling cooling to room temperature. In addition, in this controlled cooling, the structure of the bar steel is controlled by changing the amount of water and the water cooling time. After cooling, the steel bar was tempered by staying in the furnace heated to the atmospheric temperature shown in Tables 1 and 2 for the time shown in Tables 1 and 2. The steel bars after tempering are allowed to cool.

[0065] The structure of the D / 4 part of the quenched steel bar and the structure of the D / 4 part of the tempered steel bar were observed with an electron microscope (5000 times the magnification), and the martensite structure and the bainite structure were obtained. , and the area ratios of tempered martensite, tempered bainite, and regenerated pearl...

Embodiment

[0140] Using a steel material with a C content of 0.53 mass%, a Si content of 0.23 mass%, a Mn content of 0.8 mass%, a S content of 0.018 mass%, a Cr content of 0.30 mass%, and a B content of 0.015 mass%, the diameter is formed by rolling. After the 30mm steel bar is heated to 780°C, it is then controlled to cool to room temperature. After cooling, the steel bar is tempered by staying in a furnace heated to an ambient temperature of 660° C. for 15 minutes. The steel bars after tempering are allowed to cool. More preferably, the heating temperature is 820°C, and the atmosphere temperature during tempering is 690°C.

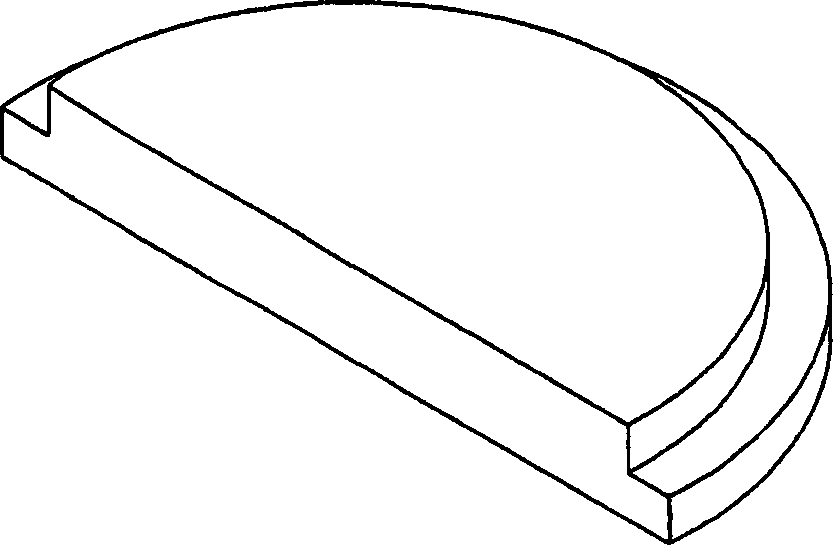

[0141] The bar steel obtained in this way was drawn to have a diameter of 27.5 mm, and then cut to form a flat portion 21 , and rack teeth 8 a were formed on this flat portion 21 as the rack tooth forming portion 22 . Next, heat the rack tooth forming part 22 for 5.5 seconds, and then perform induction quenching with a cooling time of 10 seconds by water cooling,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com