Dielectric ceramic composition, electronic component, and method for manufacturing the same

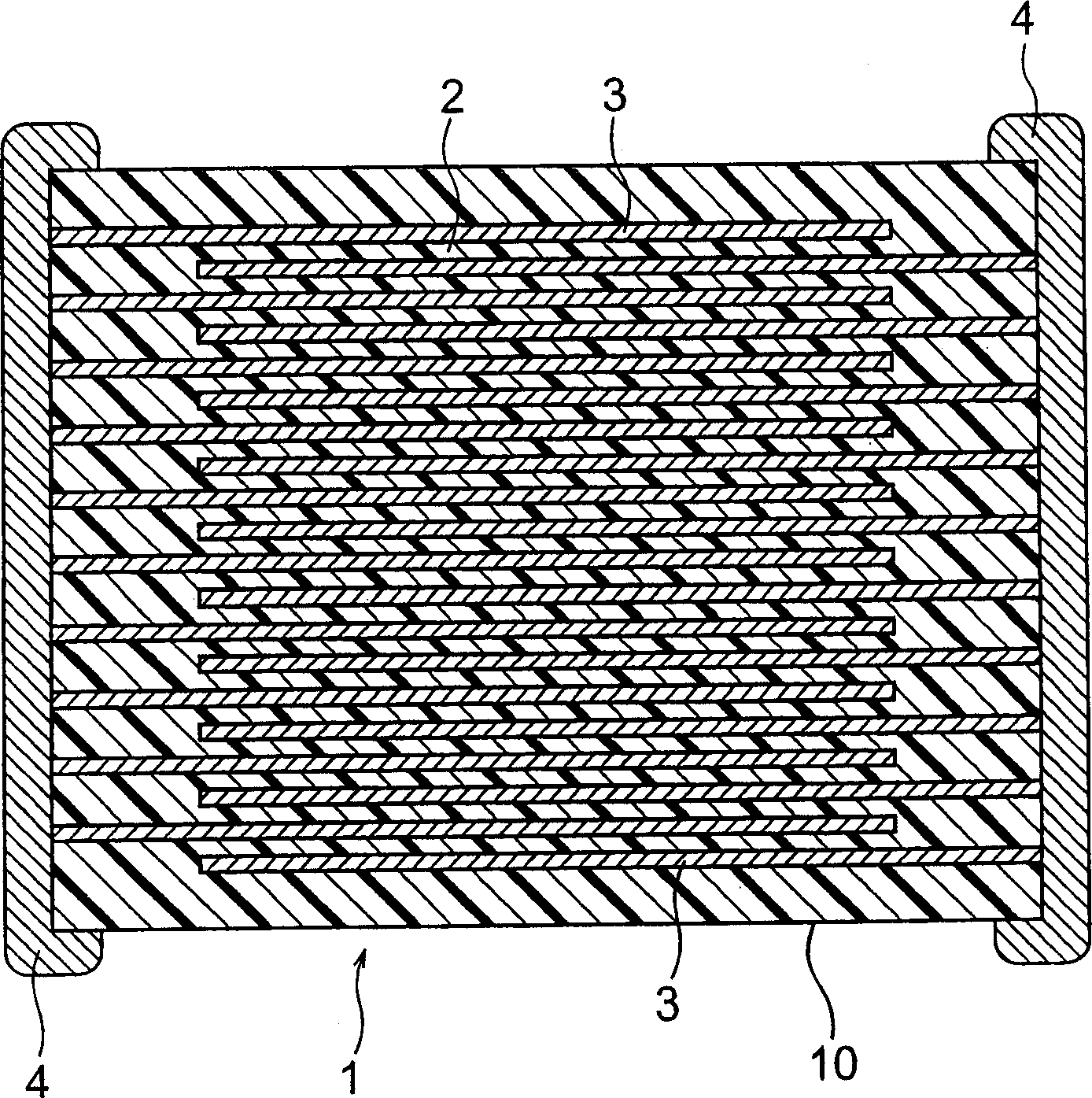

A manufacturing method and dielectric technology, which is applied in the direction of fixed capacitor dielectric, fixed capacitor parts, laminated capacitors, etc., can solve the problems of high sintering furnace price, reduced capacitor dielectric constant, and increased energy cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Modulation of Dielectric Raw Materials

[0128] First, SrCO with an average particle size of 0.4 μm was prepared as the starting material for the preparation of the main component raw material. 3 , CaCO 3 、TiC 2 , ZrO 2 and HfO 2 .

[0129] Then, according to the final composition [Ca 0.7 Sr 0.3 ]O][((Ti 0.05 Zr 0.9 f 0.05 )O 2 ] atomic ratio, weigh the prepared initial raw materials.

[0130] Next, 1 mole of MnCO was added to a total of 100 moles of the weighed starting materials. 3 , 0.5 moles of Al 2 o 3 , 3 moles of (Ba 0.6 Ca 0.4 ) SiO 3 (BCG) as the first glass composition. In addition, a specific weight % of B-Al-Zn-Si-based glass frit was added as a second glass composition to a total of 100% by weight of each starting material after weighing, and a powder before firing was obtained after the addition.

[0131] Next, the obtained pre-calcination powder was calcined. Calcination conditions are as follows. Heating rate: 200°C / hour, holding temp...

Embodiment 2

[0161] As B-Al-Zn-Si-based glass frit, except for using Na 2 O, consisting of 25% by weight of B 2 o 3 , 25 wt% ZnO, 25 wt% SiO 2 , 25 wt% Al 2 o 3 In the same manner as sample 6 of Example 1, except that it had a configuration and a softening point of 650° C., a disk-shaped sample and a capacitor sample were prepared and evaluated in the same manner (sample 13). Table 2 shows the results.

[0162] Sample No.

[0163] As shown in Table 2, it can be considered that, as the second glass composition, using 2 The B-Al-Zn-Si-based glass frit of O was sintered at a low temperature as in the case of sample 6, and the sintered density did not decrease significantly, and the average crystal grain size of the dielectric particles was also suitable, and a good frit was obtained. insulation resistance.

Embodiment 3

[0165] As the B-Al-Zn-Si glass frit, in addition to using 35% by weight of B 2 o 3 , 10 wt% ZnO, 35 wt% SiO 2 , 5 wt% Al 2 o 3 , 5% by weight Na 2 Except having a composition of O and having a softening point of 610° C., a disk-shaped sample and a capacitor sample were prepared in the same manner as in Sample 6 of Example 1, and evaluated in the same manner. As a result, the same result was obtained. In addition, this Example is an example of the case where the composition of a glass frit falls within the optimum range of this invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com