Method for preparing CdSe quantum

A technology of quantum dots and content, applied in the field of synthesis of CdSe quantum dots, can solve the problems of expensive toxicity, high comprehensive cost, unfavorable large-scale production, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: CdSe quantum dot preparation:

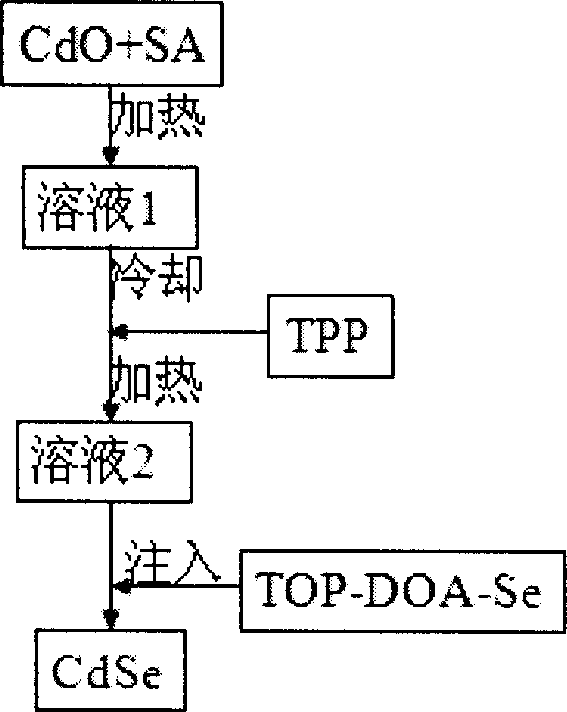

[0022] The process can be seen figure 1 .

[0023] A: Take 70mg of Se, 5g of TOP, and 15g of DOA, mix them and heat them properly in an Ar atmosphere, and dissolve them completely to become a Se stock solution.

[0024] B: Take 23mg of CdO and 0.7g of stearic acid, co-heat to 160°C in an Ar atmosphere, and cool to obtain a white solid. 2.05 g of TPP was added and co-heated to 250°C under Ar atmosphere to obtain a clear solution.

[0025] C: Take 1.2ml of Se stock solution, inject it into the Cd solution at 250°C, react for 120 seconds, cool down, add methanol to precipitate, and centrifuge to collect the precipitate.

[0026] Inspection of CdSe quantum dots:

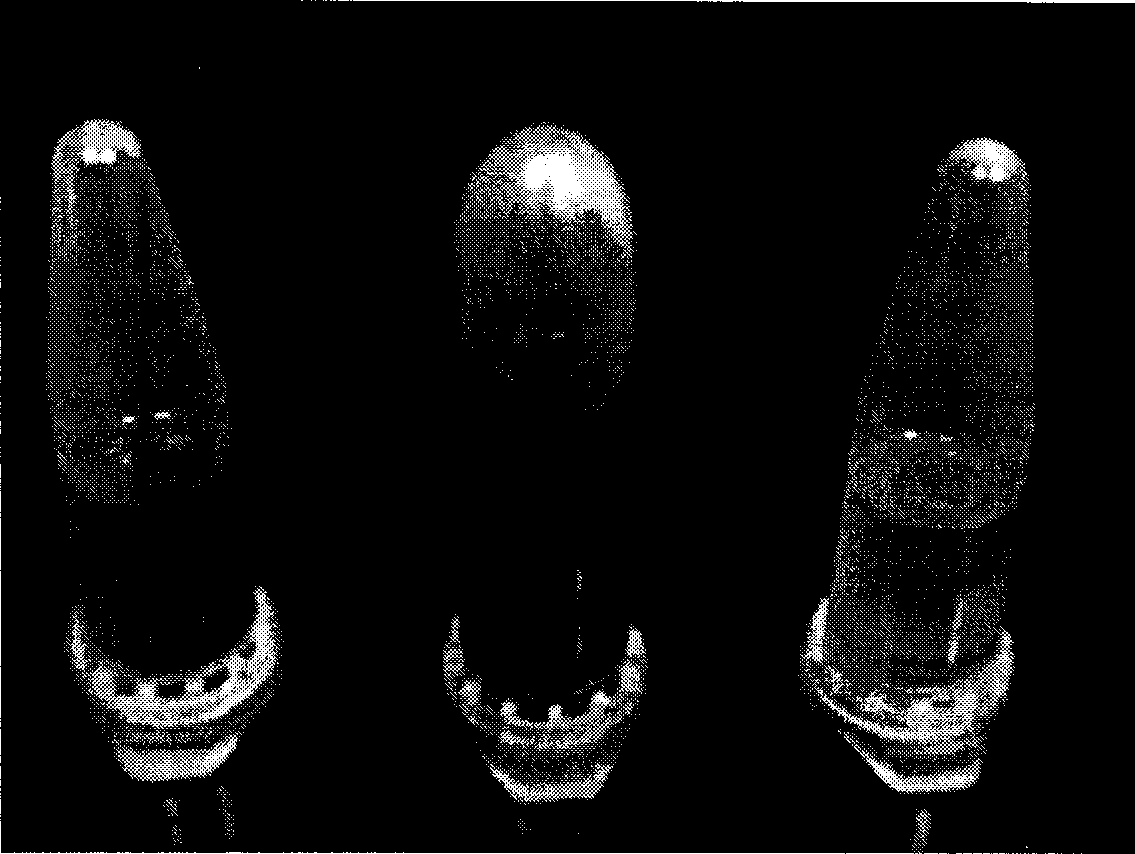

[0027] A: Dissolve the precipitate with hexane (or organic solvents such as toluene and chloroform), and use centrifugation to remove the precipitate to obtain a clear and transparent solution, such as figure 2 shown. Place the solution under a UV lamp, and you sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com