Gas nozzle for a welding torch, welding torch having a produced patina layer; cleaning device for a welding torch having bristles made of a soft elastic material and abrasive grains embedded in these

A gas nozzle and cleaning device technology, which is applied in the field of gas nozzle cleaning devices, can solve the problems that spatter cannot be removed or peeled off, and spatter cannot be separated, so as to increase service life, reduce spatter adhesion, and improve heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

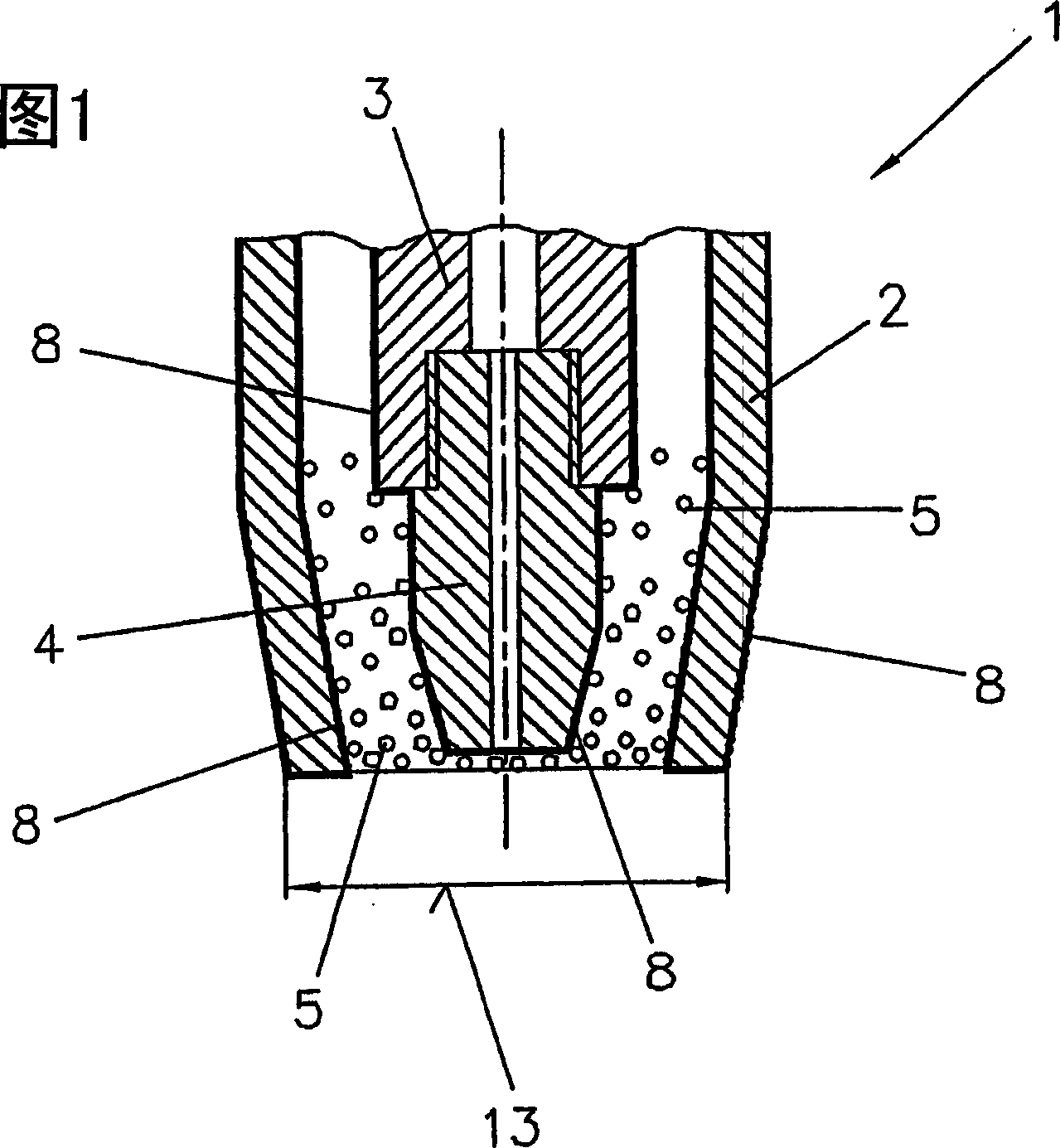

[0033] FIG. 1 shows a cutaway portion of a welding torch 1 , in particular the end region relevant for the welding process. The welding torch 1 includes a gas nozzle 2 , a nozzle assembly 3 and a conductive tube 4 . Other components of the welding torch 1 are omitted for clarity purposes. Furthermore, the structure and configuration of the components shown are not limited to the exemplary embodiment shown, and the solution according to the invention can be applied to any welding torch 1 or its components known from the prior art.

[0034] The gas nozzle 2 shown in FIG. 1 is made of copper or a copper alloy, and is detachably fixed to the welding torch 1 . The conductive tube 4 and nozzle assembly 3 arranged in different structures in each torch are also made of copper or copper alloy, and the conductive tube 4 is detachably connected to the nozzle assembly 3 . A description of the functional modes of these components and their tasks is omitted since these are well known in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com