Process for preparing nitrigen-aluminium co-blended hole zinc oxide thin film material

A zinc oxide thin film and preparation process technology, applied in semiconductor/solid-state device manufacturing, laser parts, semiconductor lasers, etc., can solve the problems of low carrier mobility, difficulty, enhanced self-compensation effect, etc., and achieve strong room temperature ultraviolet Effects of luminescent properties, uniform grain size, and strong crystalline properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

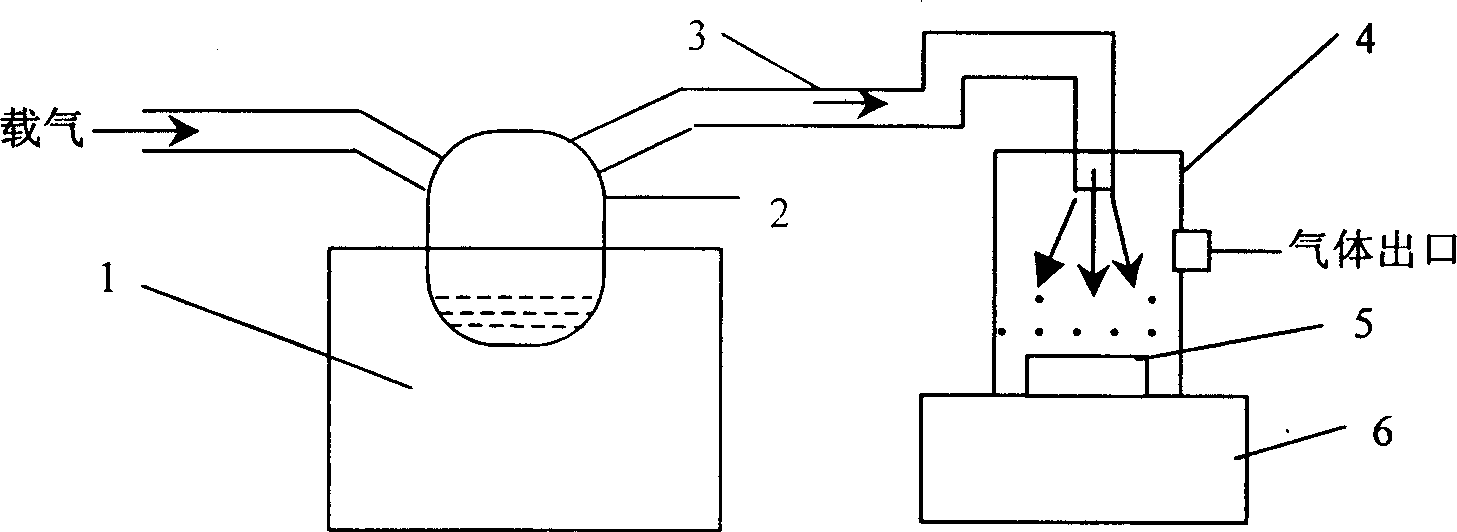

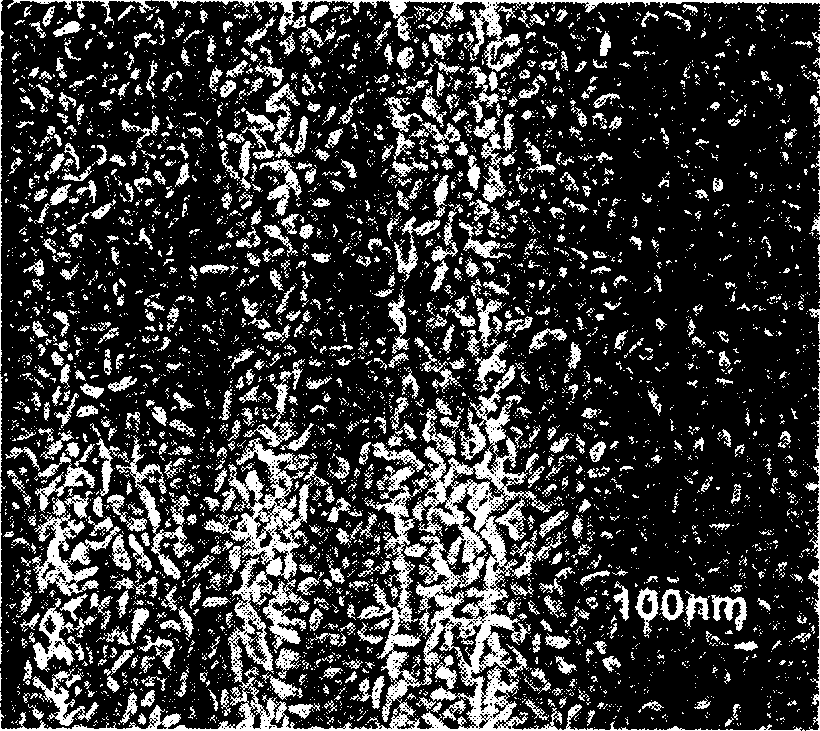

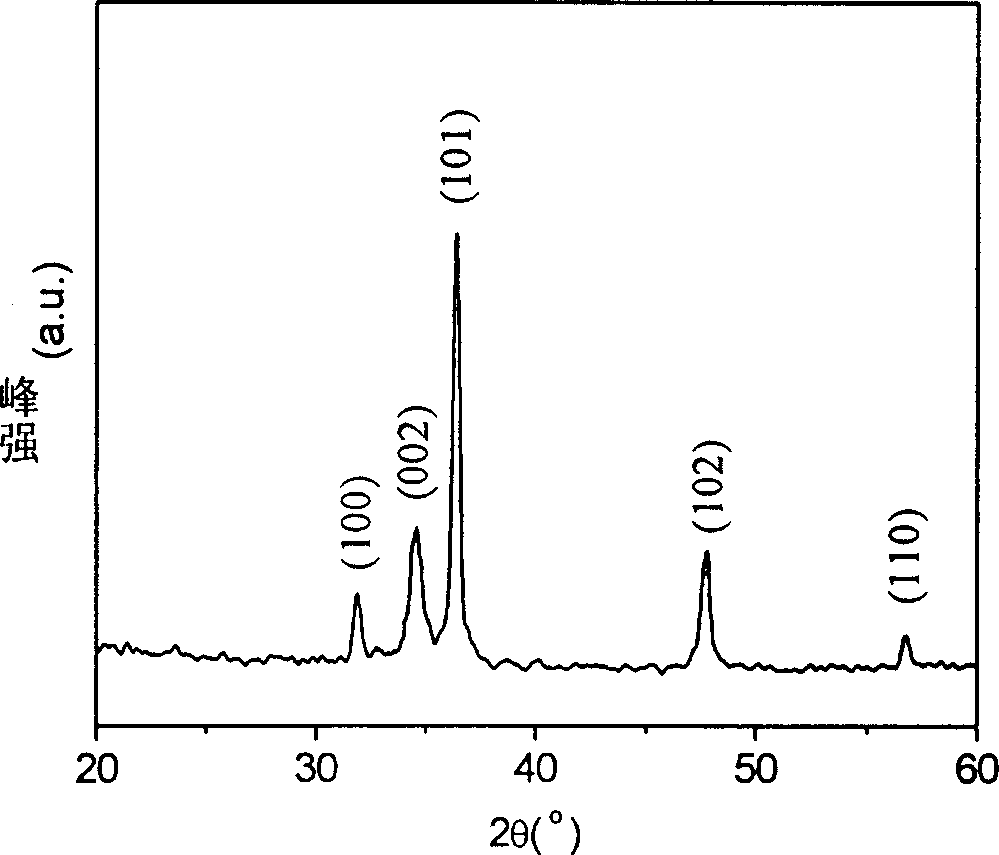

[0037] The substrate is a (100) plane single crystal silicon wafer. The ratio of the precursor solution is: 1M Zn(CH 3 COO) 2 5mL, 5M CH 3 COONH 4 3mL, 0.5M Al(NO 3 ) 3 0.5mL. The solvent used was deionized water. Pour the prepared precursor solution into the ultrasonic atomization cup. After the single crystal (100) silicon wafer was etched with hydrofluoric acid for 3 minutes, it was immediately fixed on the furnace plate, and the furnace plate was heated to 700 ° C. After the substrate reached the set temperature, the ultrasonic atomizer was started to Pure N 2 (99.999%) as the carrier gas, while the film-forming chamber maintains an atmospheric atmosphere. The atomized gas enters the film-forming chamber through the gas-liquid separation tube, and the distance between the nozzle and the substrate is kept at about 5 cm, and the spraying is stopped for about 10 minutes. Precursor solution consumption rate is O.2ml / cm 2 min. After incubation at 700°C for 5 minutes,...

Embodiment 2

[0040] The ratio of the precursor solution is: 1M Zn(CH 3 COO) 2 5mL, 5M CH 3 COONH 4 2mL, 0.5M AlCl 3 0.5mL. The substrate temperature was 650°C. The spray time is 6 minutes. After the deposition of the thin film, it was kept at 650° C. for 5 minutes and then lowered to room temperature. Other conditions are the same as Example 1. The Hall effect test of the grown ZnO thin film shows that the conductivity type is p-type, that is, hole conduction. Resistivity 1.6×10 -2 Ωcm, carrier mobility 103cm 2 V -1 the s -1 , carrier concentration 3.81×10 18 cm -3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com