Nano carbon black with in-situ grafted organic compound and its producing method

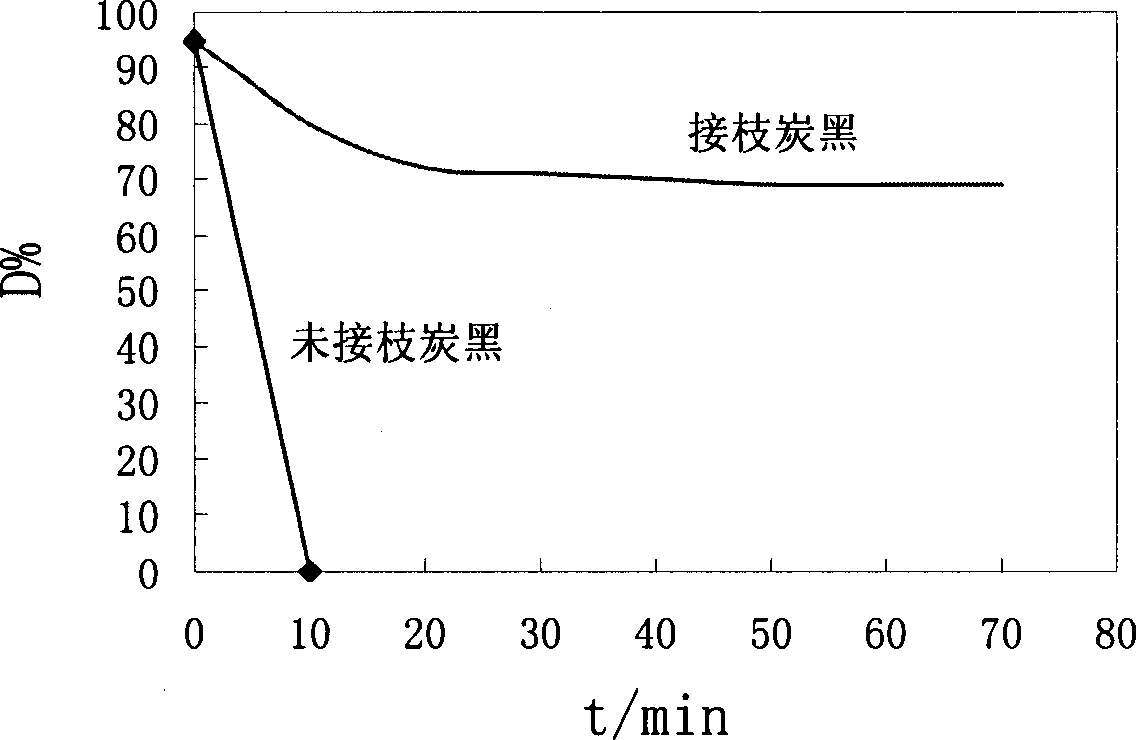

A technology of organic compounds and nano-carbon black, which is applied in dyeing low-molecular organic compound treatment, fibrous fillers, etc., can solve problems such as difficult results, low polymer reactivity, failure to destroy the agglomeration structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0349] Nano-carbon black using antioxidant AO-80: 100 parts of carbon black (N220, Mitsubishi Chemical Industry Co., Ltd.), and 80 parts of AO-80 (Asahi Denka Kogyo Co., Ltd.).

[0350] AO-80 is a hindered phenolic antioxidant, AO-80 is its trade name, and its chemical name is 3,9-bis{1,12methyl-2[β-3-tert-butyl-4-hydroxy-5 -cresol]propionyloxy}ethyl)}-2,4,8,10-tetraoxaspiro[5,5]undecane, with a melting point of 125°C, capable of producing active free radicals, the molecular formula is as follows:

[0351]

[0352] The carbon black and AO-80 were melt-blended in a Haake rheometer at 140° C. higher than the melting point of AO-80 (125° C.), the rheometer rotation speed was 60 rpm, and the blending time was 30 minutes. When the blending time reaches about 3.5 minutes and the temperature rises to 175°C, the torque of the mixture of AO-80 and carbon black increases sharply, and the torque tends to a stable value after the reaction is complete.

[0353] The reaction product of ...

Embodiment 2

[0364] Nano carbon black using antioxidant AO-60: 100 parts of carbon black (N220, Mitsubishi Chemical Industry Co., Ltd.), 80 parts of AO-60 (Asahi Denka Co., Ltd.).

[0365] AO-60 is also a hindered phenolic antioxidant. AO-60 is its trade name and its chemical name is 4[β-(3,5-di-tert-butyl-4-phenol)propionyloxy]methane. The structural formula is as follows, The melting point is 115°C, and it can also generate active free radicals.

[0366]

[0367] Except that the set temperature of the Haake rheometer was 130°C in the experiment, other conditions were the same as in Example 1. The particle size distribution determined by the laser scattering particle size analyzer is shown in Table 4.

[0368] Size(nm)

[0369] The particle size of the obtained carbon black is also about 50nm, it can form a stable suspension in acetone, and its dispersion performance is very good. The general physical properties of carbon black are also similar to Example 1.

Embodiment 3

[0371] Nano carbon black using light stabilizer LA-57: 100 parts of carbon black (N220, Mitsubishi Chemical Industry Co., Ltd.), 80 parts of LA-57 (Asahi Denka Kogyo Co., Ltd.).

[0372] LA-57 is a light stabilizer, LA-57 is its trade name, and its standard name is 2,2,6,6-tetramethyl-4-piperidinyl-1,2,3,4-butyrate , the structural formula is as follows, the melting point is 132°C, and it can generate active free radicals.

[0373]

[0374] In the experiment, the set temperature of the Haake rheometer was 150°C, and the blending time was extended to 40 minutes. All the other conditions are the same as in Example 1. The particle size distribution measured by the laser scattering particle size analyzer is shown in Table 5.

[0375] Size(nm)

[0376] The particle size of the obtained carbon black is less than 100nm, the monodispersity is very good, and a stable suspension can be formed in acetone. The general physical properties of carbon black are also similar to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com