Production of hafnium nitride thin-membrane materials from ion beam epitaxial growth apparatus

An epitaxial growth, thin film material technology, applied in ion implantation plating, metal material coating process, semiconductor/solid-state device manufacturing, etc., can solve the problem of expensive raw materials, difficult to purify transition group IVB refractory metal nitrides, etc problem, to achieve the effect of high-quality chemical ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

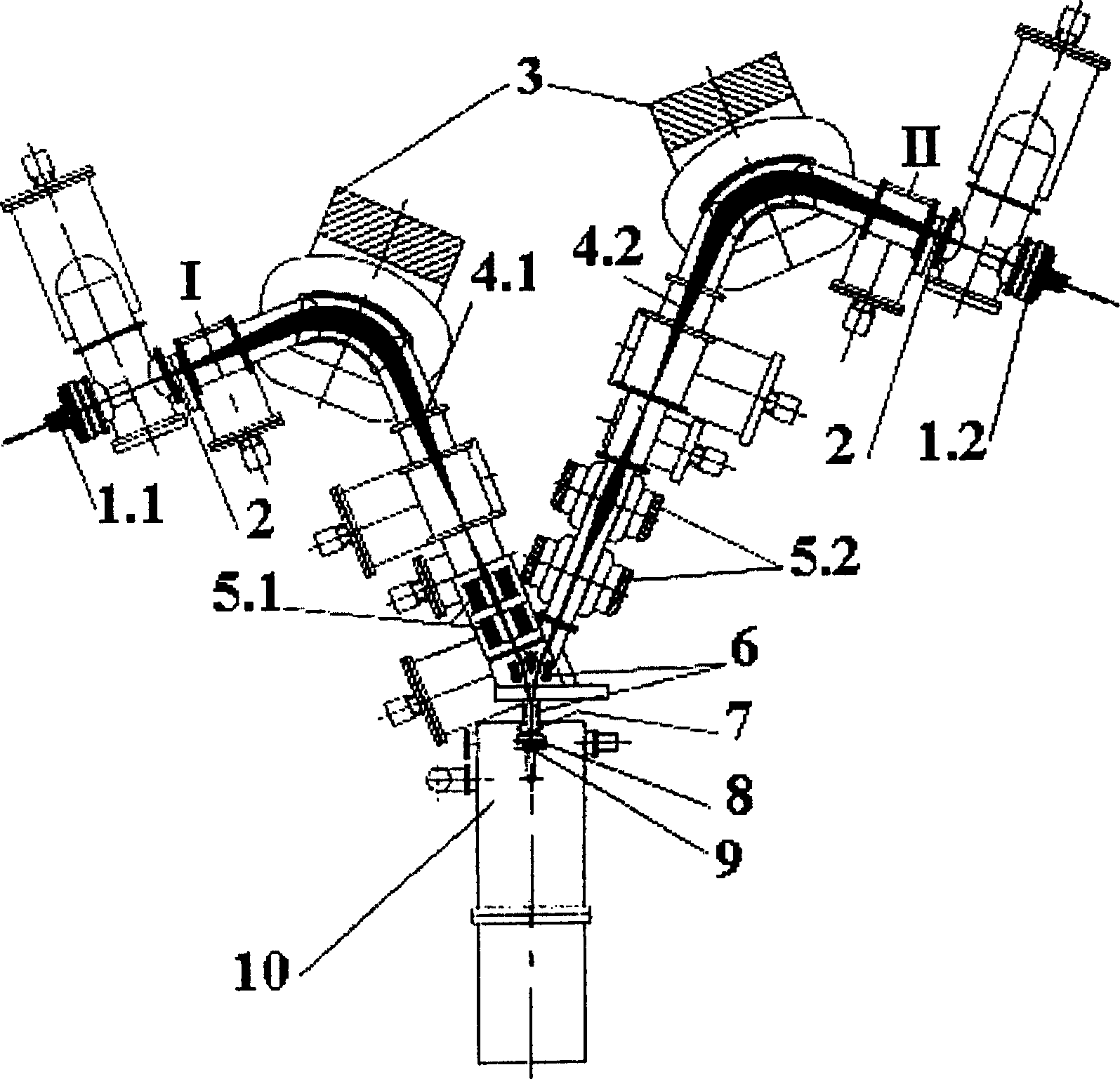

[0072] The preparation of hafnium nitride (HfN) thin film materials is carried out on an ion beam epitaxy system with a double-beam structure, and hafnium chloride (HfCl) with low purity requirements is selected. 4 ) solid powder and nitrogen as the two ion sources of the dual ion beam epitaxy system to generate metal hafnium ions (Hf + ) beam and nitrogen ions (N + ) bundle of raw materials, reducing the cost of raw materials for the preparation and growth of hafnium nitride (HfN) thin film materials;

[0073] Using the mass separation function and ion deceleration function of the ion beam epitaxy growth equipment, the isotopically pure and low-energy metal hafnium ions (Hf + ) beam and nitrogen ions (N + ) beam, and the preparation and growth of thin film materials in an ultra-high vacuum growth chamber without any auxiliary working gas, and realized the high-purity growth of hafnium nitride (HfN) thin films that are difficult to purify;

[0074] Isotopically pure low-ene...

Embodiment

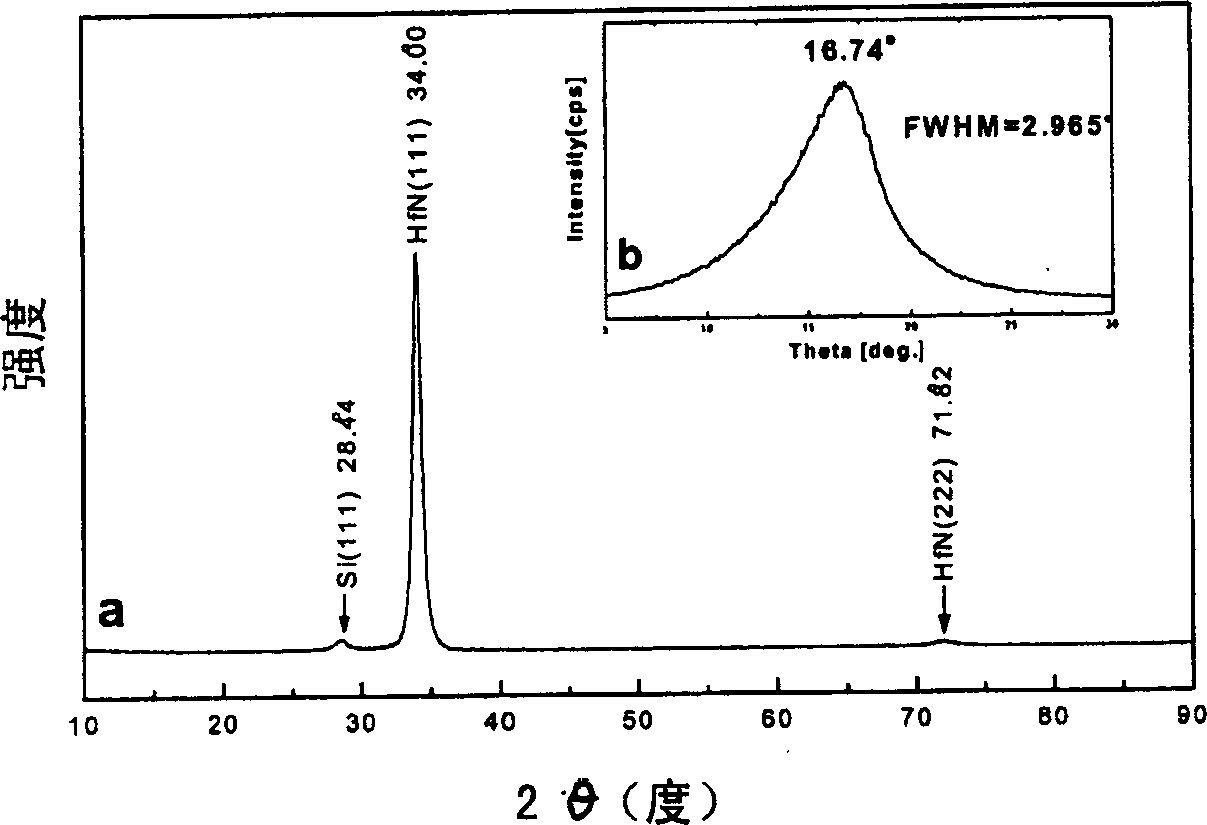

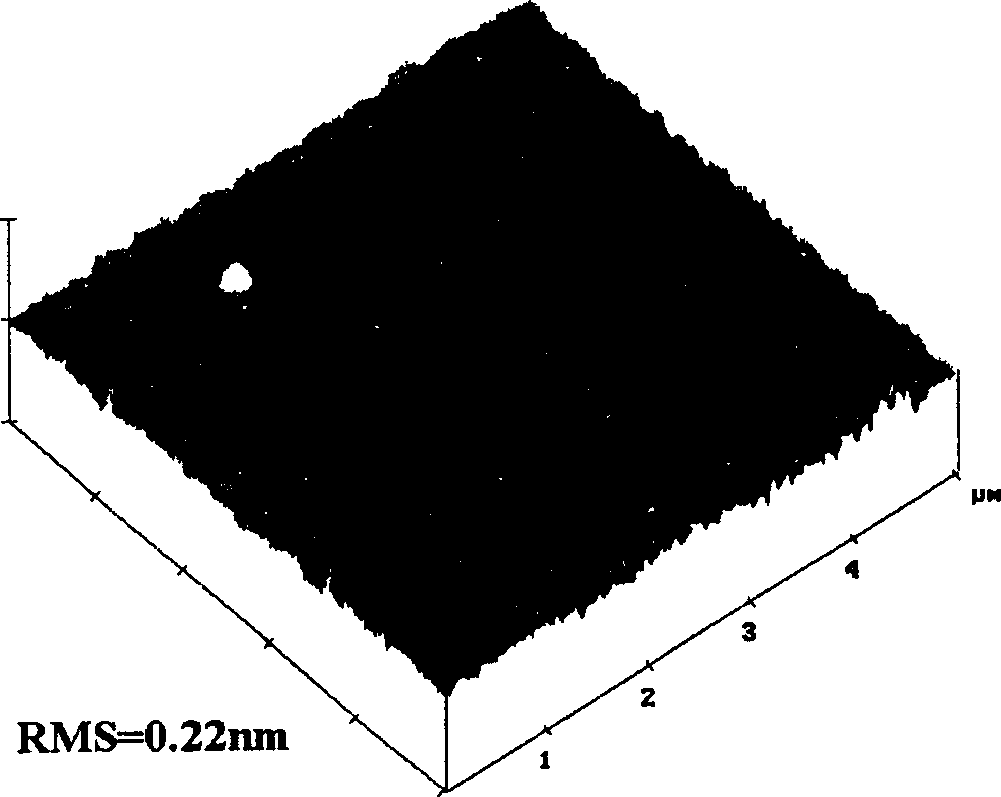

[0082] Concrete embodiment sees the relevant experimental data of table 2 and figure 2 , 3 , 4, 5, 6 experimental results.

[0083]

Berners-type solid ion source

Bundle II

Berners-type gas ion source

Ion source raw material

(purity 98.5%)

Nitrogen (N 2 )

(purity 99.5%)

ion

the source

to bake

Degas

parameters

I 灯丝加热

20A

30A

I 弧室加热

10A

I 坩埚加热

5A

T 坩埚温度

140℃

140℃

P 离子源烘烤前后真空

1.5×10 -3 Pa

2.5×10 -4 Pa

ion

the source

secondary

heat up

parameters

I 灯丝加热

30A

I 弧室加热

10A

I 坩埚加热

5A

T 坩埚温度

160℃

P 源1工作前气压

2.6×10 -3 Pa

ion

the source

Work

parameters

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com