Reinforcement treatment of bisphenol waste water

An enhanced treatment, bisphenol technology, applied in water/sewage treatment, chemical instruments and methods, light water/sewage treatment, etc., can solve the problems of long treatment time, transfer to another state, low degradation efficiency, etc. To achieve the effect of no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

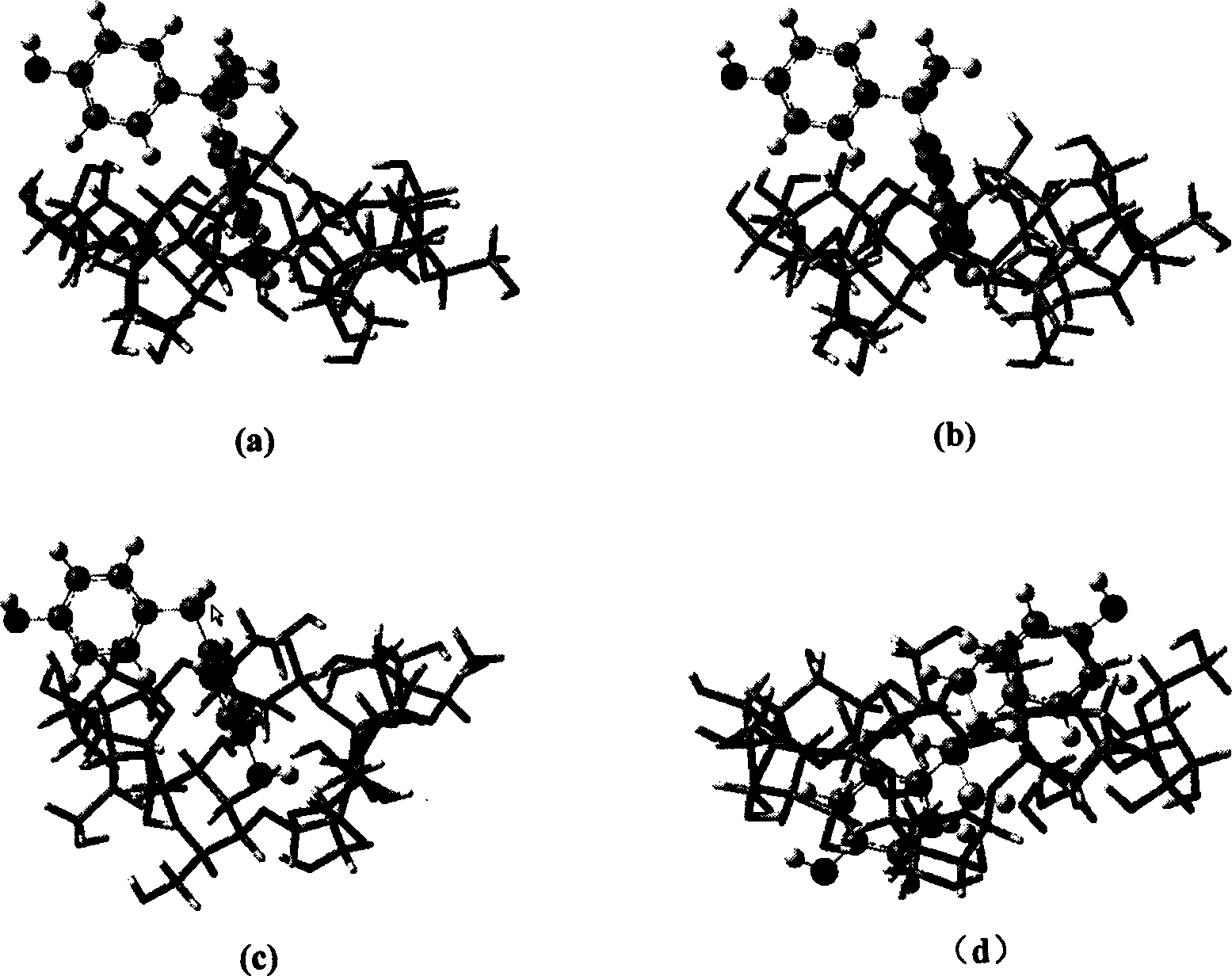

Image

Examples

Embodiment 1

[0011] Example 1: Add β-cyclodextrin to a simulated water sample containing 100 mg / L of bisphenol A (bisphenol A, BPA), the content of which is 500 mg / L, and the pH of the photoreaction solution is around 7.0. In 30 minutes, the photodegradation rate of bisphenol A after molecular recognition can be increased by 60%, and the reaction rate constant can be increased by 11.0 times.

Embodiment 2

[0012] Example 2: Add β-cyclodextrin to a simulated water sample containing 100 mg / L of bisphenol E (bisphenol E, BPE), the addition amount is 530 mg / L, the pH of the photoreaction solution is about 7.0, and the light is irradiated under ultraviolet light After 60 minutes, the photodegradation rate of bisphenol E after molecular recognition can be increased by 55%, and the reaction rate constant can be increased by 5.4 times.

Embodiment 3

[0013] Example 3: Add β-cyclodextrin to a simulated water sample containing 100 mg / L of bisphenol F (BPF), the addition amount is 570 mg / L, the pH of the photoreaction solution is around 7.0, and the light is irradiated under ultraviolet light In 60 minutes, the photodegradation efficiency of bisphenol F after molecular recognition can be increased by 40%, and the reaction rate constant can be increased by 2.3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com