Method and apparatus for preventing metal/silicon spiking in MEMS devices

A technology of micro-electromechanical structure and silicon layer, which is applied in metal material coating process, microstructure technology, microstructure device, etc., can solve problems such as increased resistivity of aluminum wire, difficulty in dry etching of alloy aluminum wire, and wrong operation of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

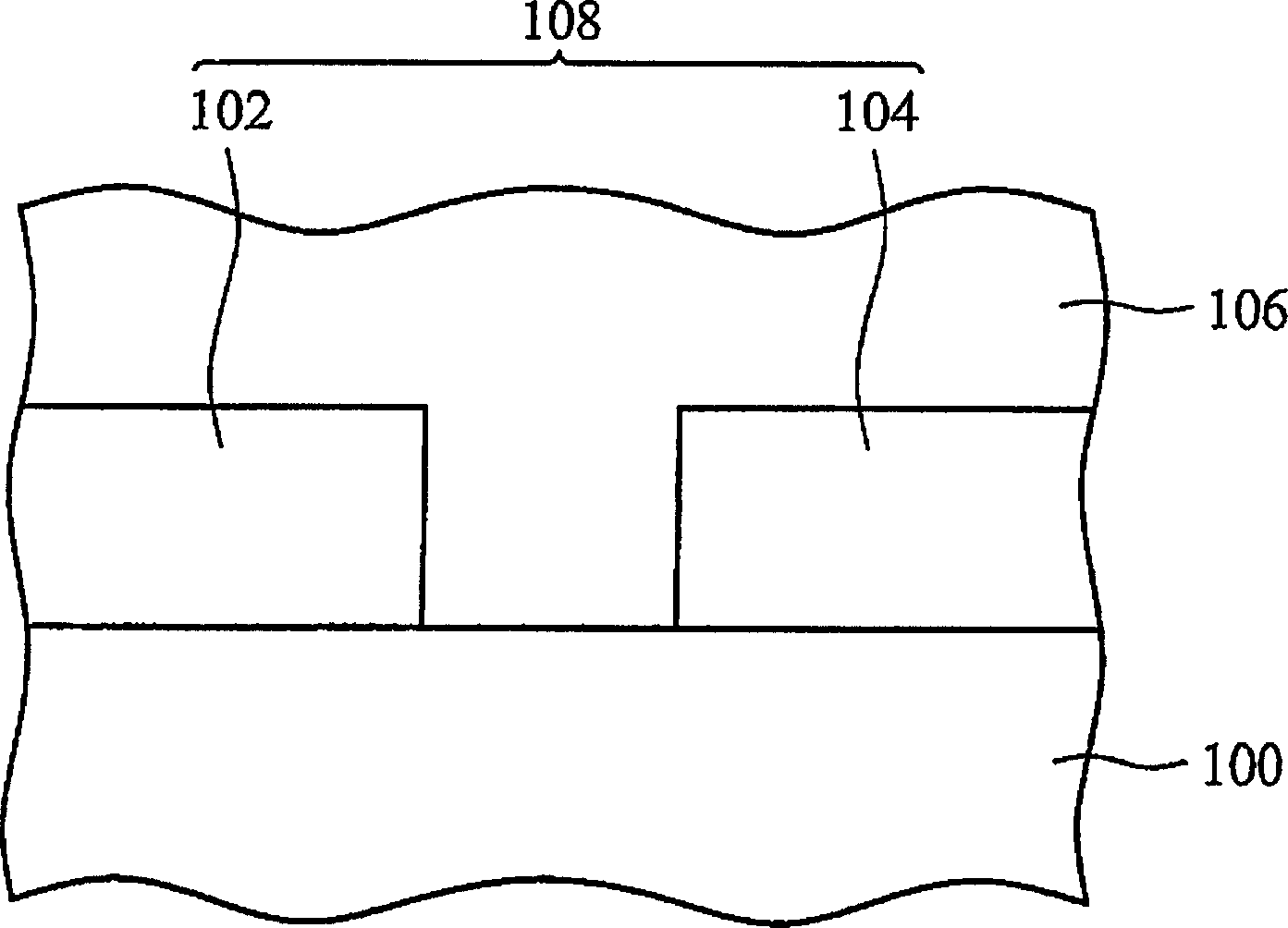

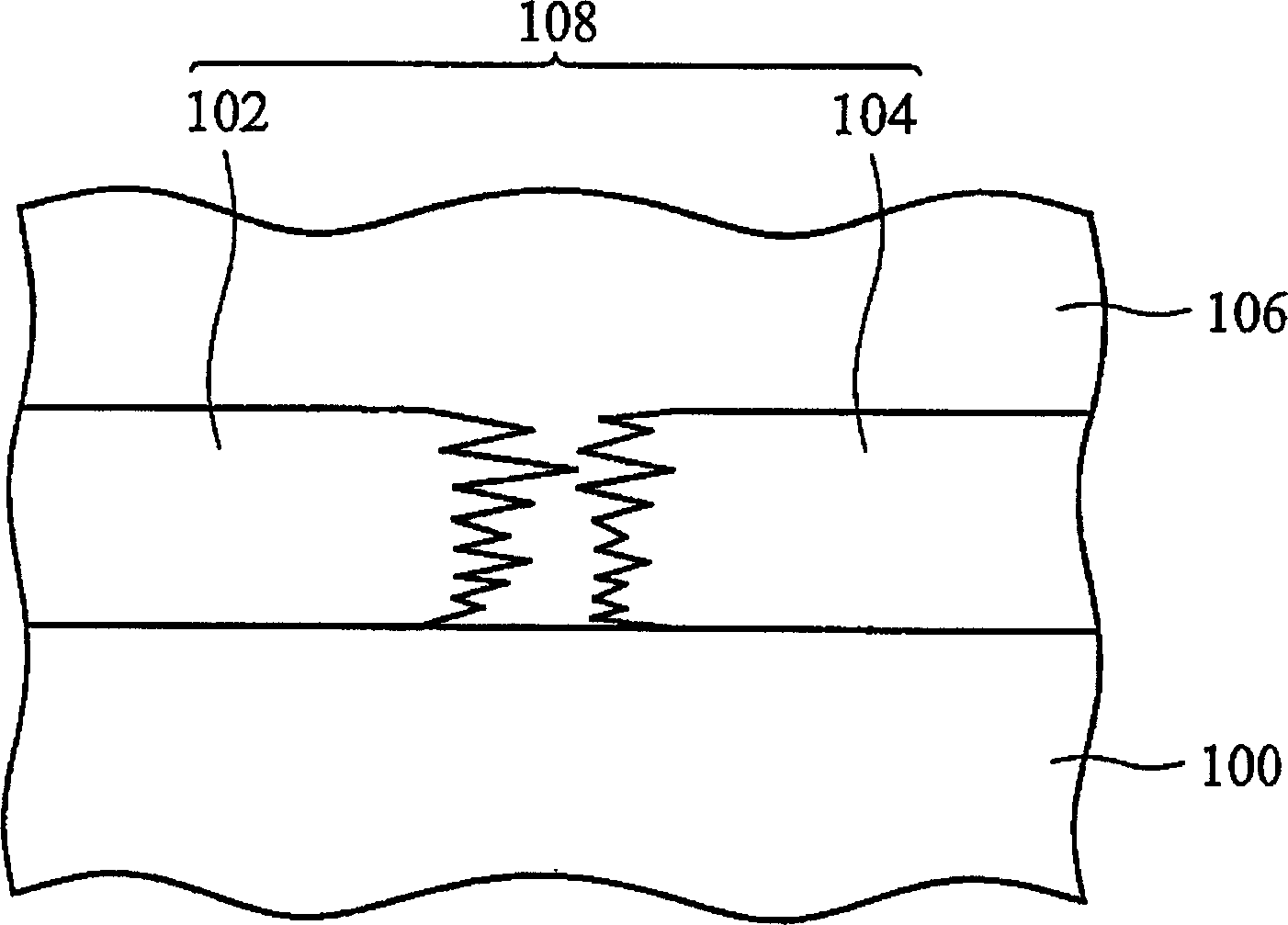

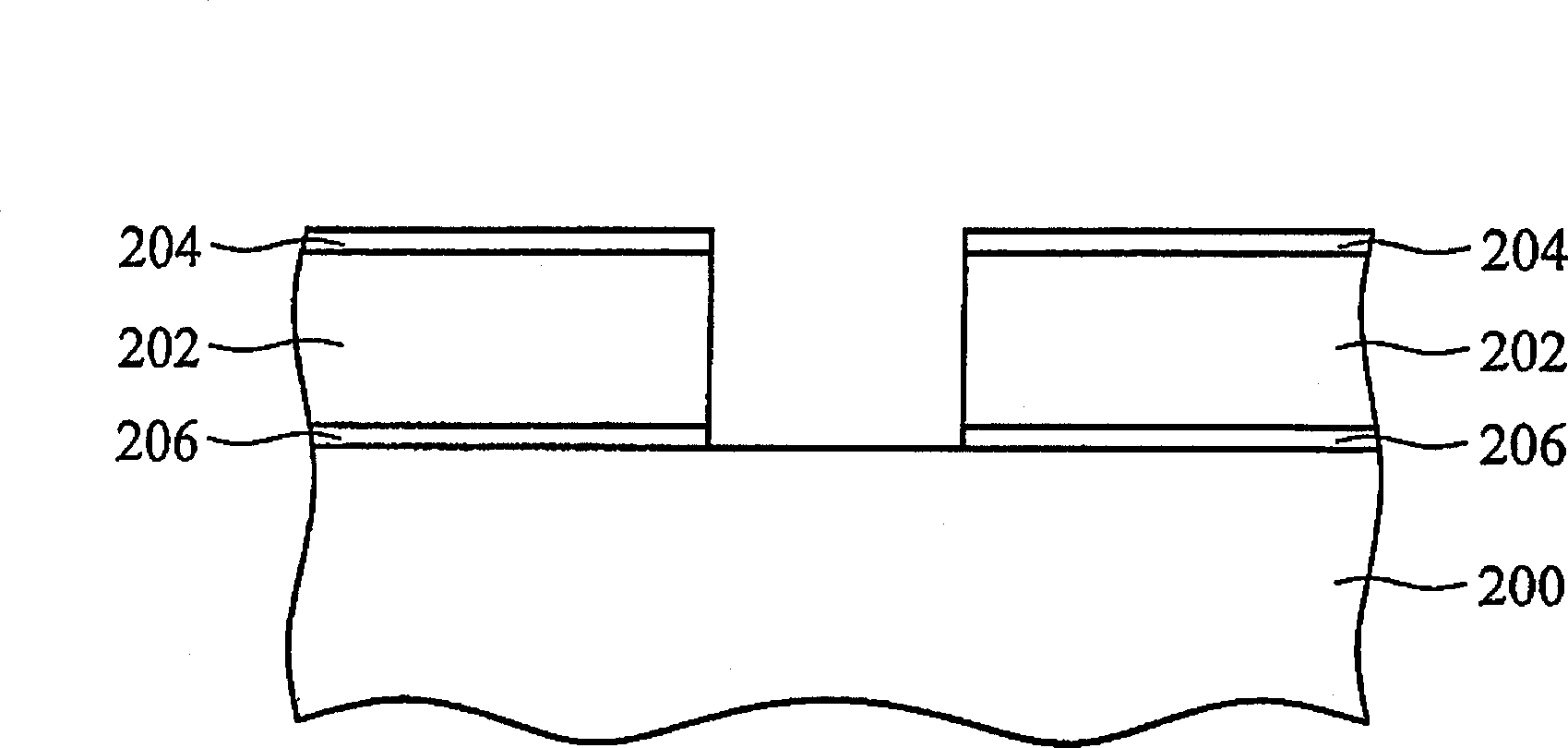

[0030] First, if Figure 2A As shown, a substrate 200 including a plurality of metal patterns 202 is provided, wherein the substrate 200 can be a semiconductor substrate or a glass substrate, and the metal patterns are composed of aluminum or a combination of aluminum, silicon, and copper. The preferred metal pattern 202 is an aluminum-silicon-copper alloy (about 1% silicon and 0.5% copper is added to the aluminum) with a thickness of 2000 angstroms to 4000 angstroms, which is deposited by sputtering and then etched back: its sputtering The method generally uses a high vacuum pump to reduce the pressure of the reaction formula to 10 -6 Below Torr, metal sputtering is then carried out in an environment with a pressure of about 1-10 mTorr by passing in an inert gas with a suitable atomic mass (generally argon). The etch back generally uses chlorides such as: SiCl 4 、BCl 3 、BBr 3 or CCl 4 Combination with chlorine gas for etching of aluminum.

[0031] The metal pattern also...

no. 2 example

[0035] First, if Figure 3AAs shown, a substrate 300 including a plurality of metal patterns 302 is provided, wherein the substrate 300 can be a semiconductor substrate or a glass substrate, and the metal patterns 302 are composed of aluminum or a combination of aluminum, silicon, and copper. Its preferred metal pattern 302 is an aluminum-silicon-copper alloy (adding about 1% silicon and 0.5% copper to aluminum) with a thickness of 2000 angstroms to 4000 angstroms, which is deposited by sputtering and then etched back: its sputtering The method generally uses a high vacuum pump to reduce the pressure of the reaction formula to 10 -6 Below Torr, metal sputtering is then carried out in an environment with a pressure of about 1-10 mTorr by passing in an inert gas with a suitable atomic mass (generally argon). The etch back generally uses chlorides such as: SiCl 4 、BCl 3 、BBr 3 or CCl 4 Combination with chlorine gas for etching of aluminum.

[0036] Its metal pattern also in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com