Supersonic spraying method for preparing vanadium pentoxide thin film

A vanadium pentoxide and thin-film ultrasonic technology, which can be applied to spray devices, liquid chemical plating, liquid spray devices, etc., can solve problems such as complex processes, and achieve simple preparation process operations, easy control of process parameters, and abundant raw material sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

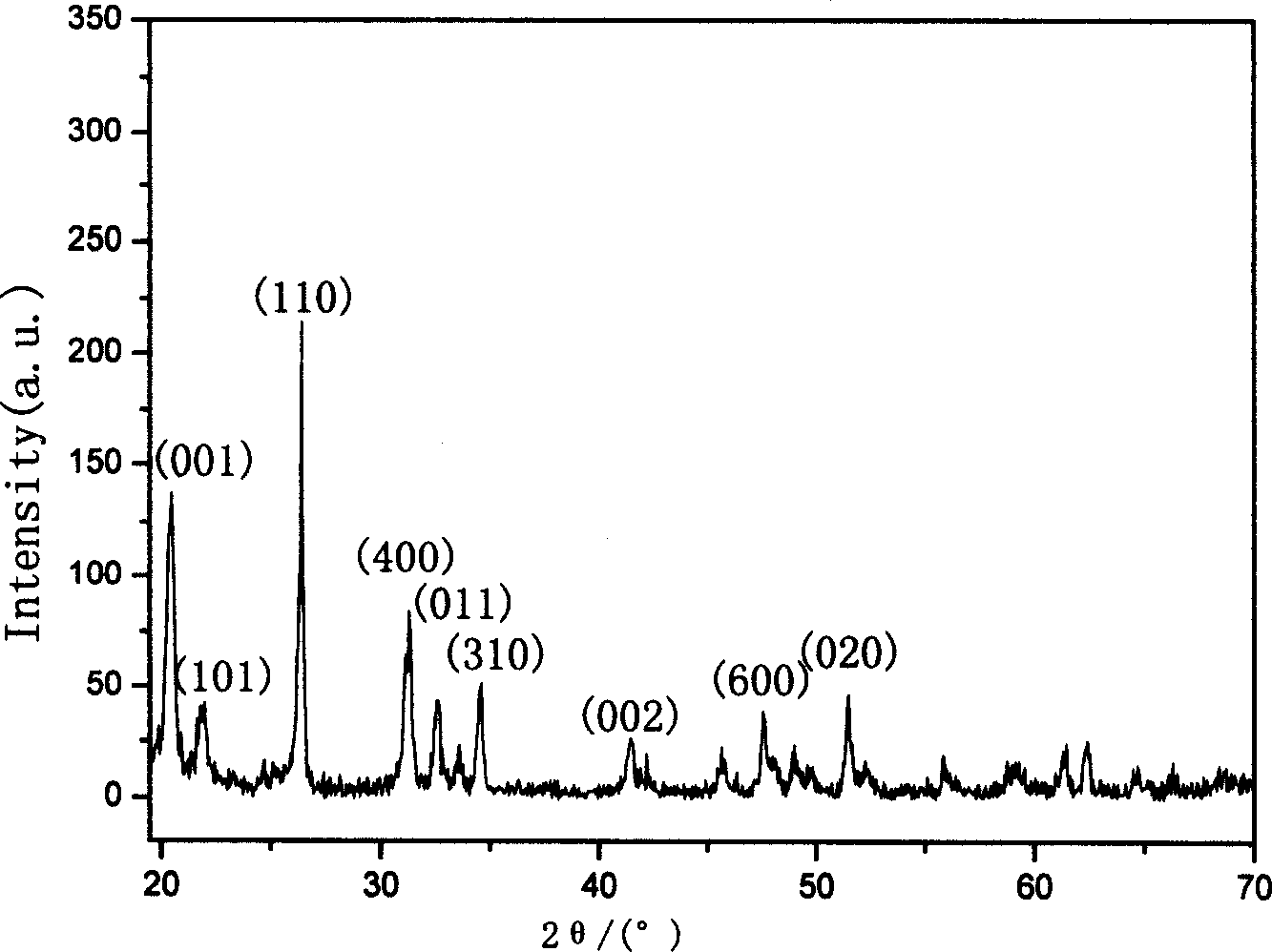

[0014] (1) Select glass as the substrate, ultrasonically clean with acetone, methanol, and deionized water successively, dry, and set aside; (2) Get excessive ammonium metavanadate powder, be dissolved in 100 milliliters of concentration and be the ammoniacal liquor of 25wt%, Stir fully, let it stand for 24 hours, filter, and configure it into a saturated ammonia solution of ammonium metavanadate at 25°C; (3) heat the substrate to 350°C, adjust the distance from the nozzle of the ultrasonic atomizer to the surface of the substrate to be 4 cm, and the mist The conversion rate is 1ml / min, the ultrasonic frequency is 1.3MHz, and the gas flow rate is 0.05m 3 / hour, the deposition time is controlled to 6 minutes, that is, V 2 o 5 film. figure 1 Shown is X-ray diffraction, indicating that the V prepared by this method 2 o 5 The film has an orthorhombic crystal structure, figure 2 The SEM surface topography is shown.

Embodiment 2

[0016] Option to plate SnO 2 The glass of thin film is made substrate, and cleaning method is the same as embodiment 1; Get excessive ammonium metavanadate powder, be dissolved in 100 milliliters of concentrations and be the ammoniacal liquor of 20wt%, fully stir, leave standstill 24 hours, filter, be configured into 25 ℃ partial Ammonium vanadate saturated ammonia solution; the substrate temperature is controlled at 450°C, the distance from the ultrasonic atomizer nozzle to the substrate surface is adjusted to 5 cm, the atomization rate is 4 ml / min, the ultrasonic frequency is 1.5 MHz, and the gas flow rate is 0.2 meters 3 / hour, and the deposition time is controlled to be 10 minutes. V 2 o 5 The film has an orthorhombic crystal structure, image 3 The SEM surface topography is shown.

Embodiment 3

[0018] Select a silicon chip as the substrate, and the cleaning method is the same as in Example 1; take 0.5 grams of ammonium metavanadate powder, dissolve it in 100 milliliters of ammonia water with a concentration of 10 wt%, stir and dissolve it fully, leave it to stand for 20 hours, and filter; Control at 550°C, adjust the distance from the ultrasonic atomizer nozzle to the substrate surface to 2 cm, the atomization rate to 8 ml / min, the ultrasonic frequency to 1.6 MHz, and the gas flow rate to 0.5 m 3 / hour, and the deposition time is controlled to be 10 seconds. V produced in this example 2 o 5 The film has an orthorhombic crystal structure, Figure 4 Shown is the surface topography of the scanning electron microscope. The surface has a spherical structure of pine nuts. The surface is rich in layered wrinkle structure and has a large specific surface area. It is very suitable for the catalyst industry and as an electrode material for high-capacity lithium batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com