Method for preparing carboxyl apatite coating by single-chamber sacrificial anode hydrothermal synthesis

A technology of hydroxyapatite and sacrificial anode, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of expensive equipment and raw materials, unsuitable for porous metal surface spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] The industrial pure titanium plate is machined into 60×10×0.8mm, polished with water-grinding paper, rinsed with water, degreased with ethanol or acetone, and dried for later use. Machining the magnesium alloy sacrificial anode to 30×20×20mm, drilling a threaded hole in the middle of the upper surface, connecting a brass rod with a thread at one end to the sample of the sacrificial anode, polishing the surface of the sacrificial anode with water abrasive paper, rinsing with water, removing with ethanol or acetone oil and dry. The upper surface of the anode and part of the surface of the brass rod are coated with silica gel.

[0029] The composition of the solution for preparing the initial coating is:

[0030] Ca(NO 3 ) 2 0.04mol / L

[0031] NH 4 h 2 PO 4 0.024mol / L

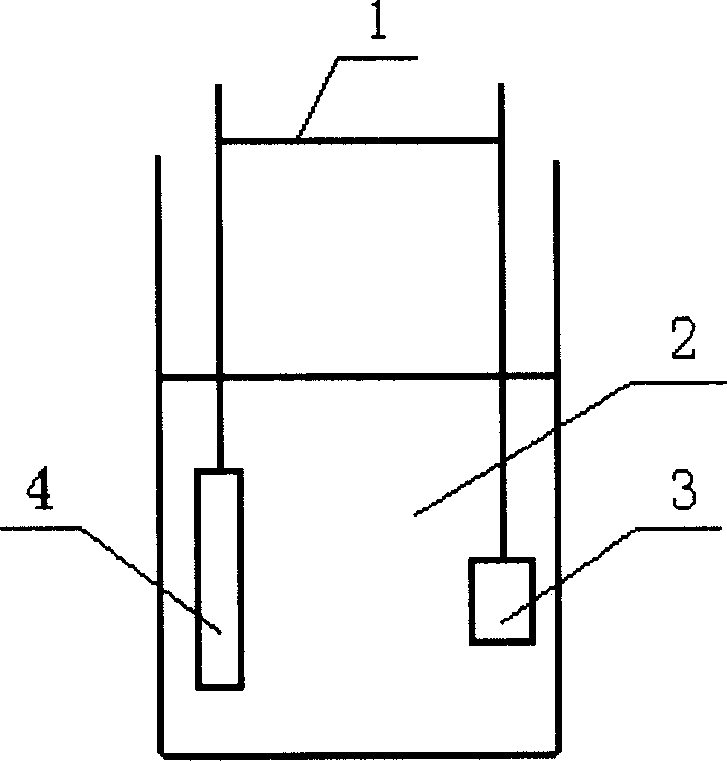

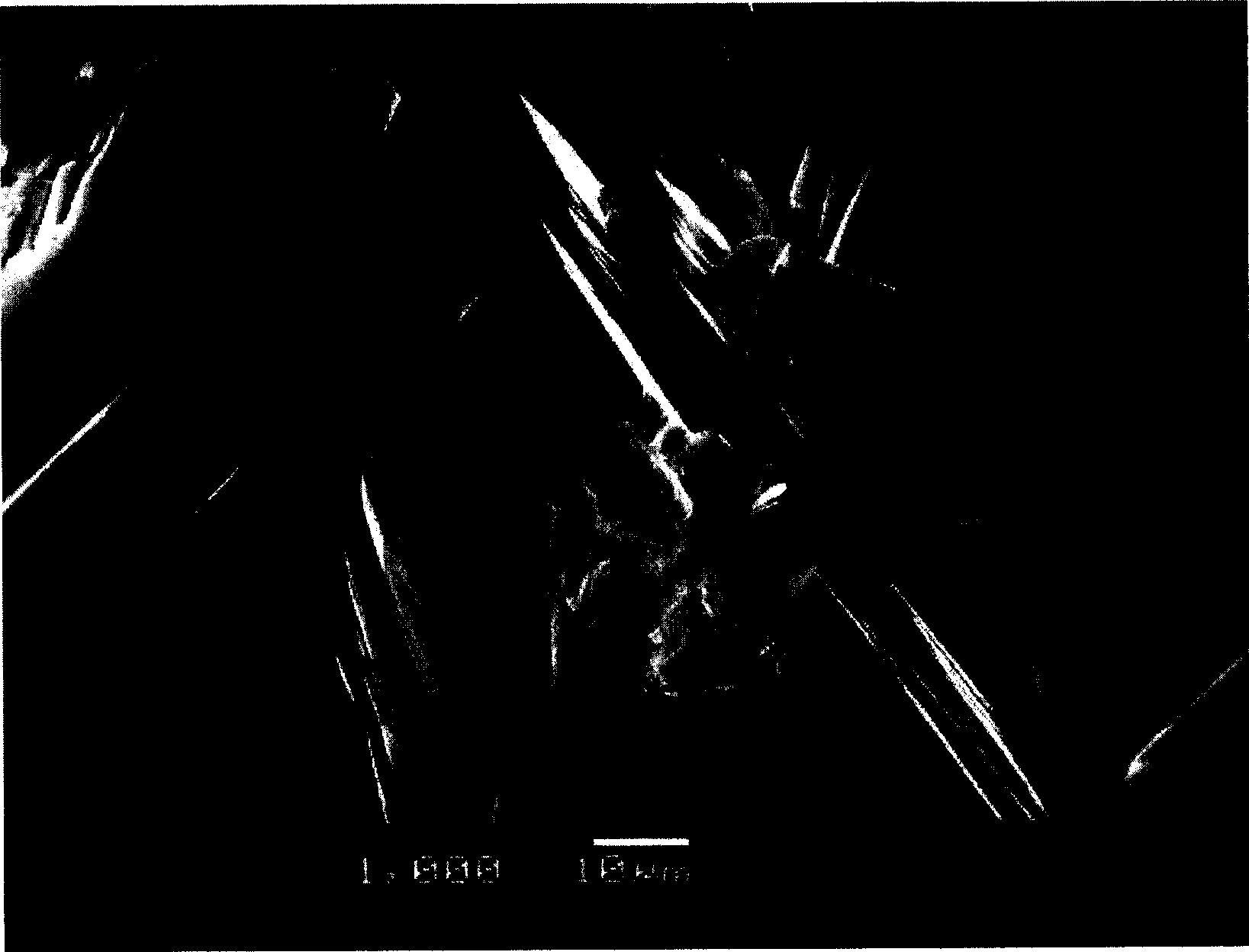

[0032] Attached at room temperature figure 1 connect. The ratio of active sacrificial anode area to titanium substrate deposition area was 3. After reacting for about 8 hours, take out th...

example 2

[0036] The Ti6Al4V alloy plate was machined into 60×10×1.5mm, polished with water-grinding sandpaper, rinsed with cold water, degreased with ethanol or acetone, and dried for later use. Refer to Example 1 for the processing method of the magnesium alloy anode.

[0037] The composition of the solution for preparing the initial coating is:

[0038] Ca(NO 3 ) 20.02mol / L

[0039] NH 4 h 2 PO 4 0.012mol / L

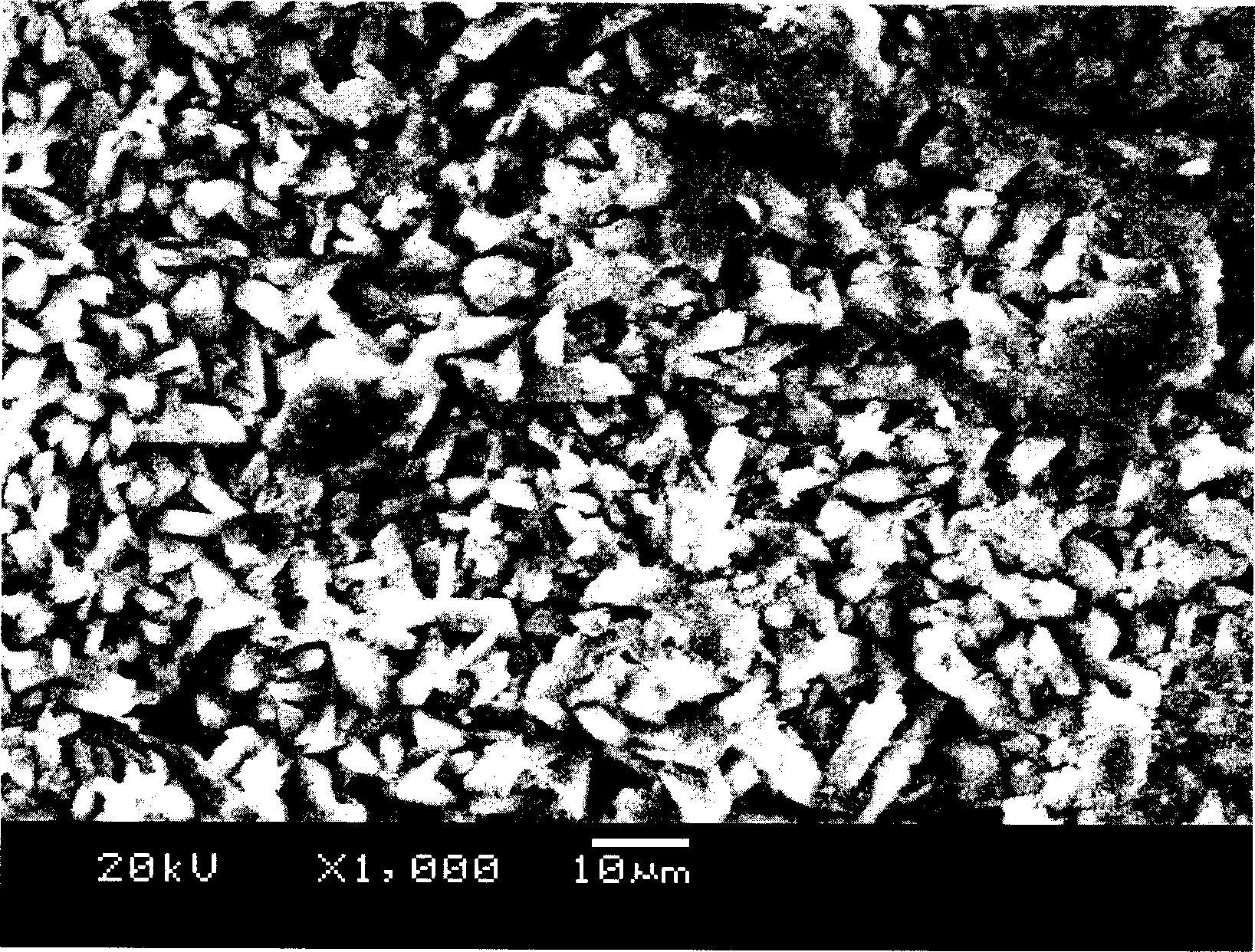

[0040] After the temperature of the solution reaches 80°C, press the attached figure 1 connect. The ratio of active sacrificial anode area to Ti6Al4V alloy substrate surface area is 3. After reacting for about 80 minutes, take out the sample, rinse it with cold water, and dry it. At this time, a coating about 110 μm thick can be deposited on the surface of the Ti6Al4V alloy plate. The coating is uniform and smooth, and it is well combined with the substrate. Electron probe analysis showed that there was no magnesium element present on the initial coating. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com