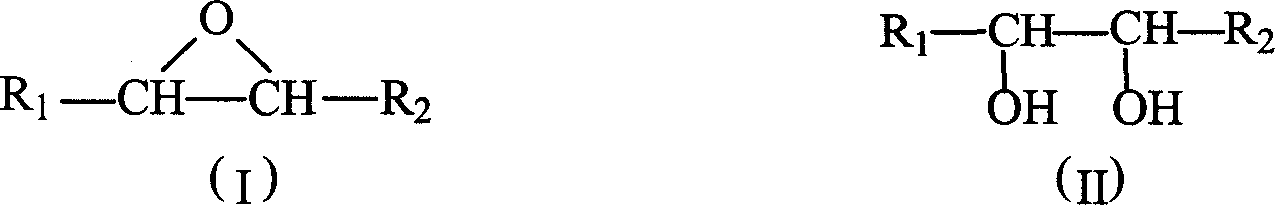

Aliphatic dihydroxy alcohol preparation method

An aliphatic dihydric alcohol and aliphatic technology, applied in the field of preparation of aliphatic dihydric alcohol, can solve the problems of high reaction water ratio, low product selectivity, high energy consumption, etc., achieve shortened process flow, and have no pollution to the environment , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Fully mix 60 grams of aluminum hydroxide raw powder and 40 grams of silicon dioxide raw powder, then add 60 milliliters of 4% (weight) dilute nitric acid, fully knead in a kneader to form a doughy material, extrude it, and heat it at room temperature drying at 150° C. for 2 hours, and calcining at 1400° C. for 4 hours to obtain a strip-shaped carrier. The above-mentioned carrier is crushed to 40-60 meshes, and loaded into the upper section of the chemical vapor deposition reactor. The reactor is a quartz reaction tube with an inner diameter of 10 mm and a length of 300 mm. The reactor is divided into upper and lower sections, and a certain number of sintered glass is installed in the middle. The reactor is heated by external heating, and two parallel thermocouples are installed outside to control and measure the heating temperature of the upper and lower sections of the reactor respectively. The upper part of the reactor is used to load the catalyst carrier, and the l...

Embodiment 2

[0023] 10 g of anatase nanoscale TiO 2 , 90 grams of silicon oxide powder and 12 grams of niobic acid at 200 kg / cm 2 Tablet molding under pressure, calcination in air at 700°C for 4 hours to obtain catalyst B. The catalyst composition is shown in Table 1.

Embodiment 3

[0025] Fully mix 113 grams of aluminum hydroxide powder, 8 grams of graphite, and 7 grams of squash powder, then add 60 milliliters of 2% (weight) dilute nitric acid, fully knead in a kneader to form a lump material, and extrude , dried at room temperature for 24 hours, dried at 150°C for 2 hours, and calcined at 1300°C for 4 hours to obtain strip-shaped α-Al 2 o 3 carrier. Then impregnate the mixed solution of aluminum nitrate and magnesium nitrate into α-Al 2 o 3On the carrier, dry at 150°C for 2 hours, and bake at 1200°C for 4 hours to obtain 2% (weight) MgAl 2 o 4 / α-Al 2 o 3 carrier. Then commercially available niobium oxalate was dissolved in water to prepare a niobium oxalate solution, which was vacuum-impregnated onto the aforementioned carrier, dried at 150°C for 2 hours, and then calcined at 300°C for 4 hours under a carbon dioxide atmosphere to obtain catalyst C. The composition of the catalyst is shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com