Self circulated cascade gas lift type internal-loop reactor system

A reactor system and reactor technology, applied in the field of chemical engineering, can solve problems such as energy consumption, and achieve the effects of fast dissolution, low mass transfer resistance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

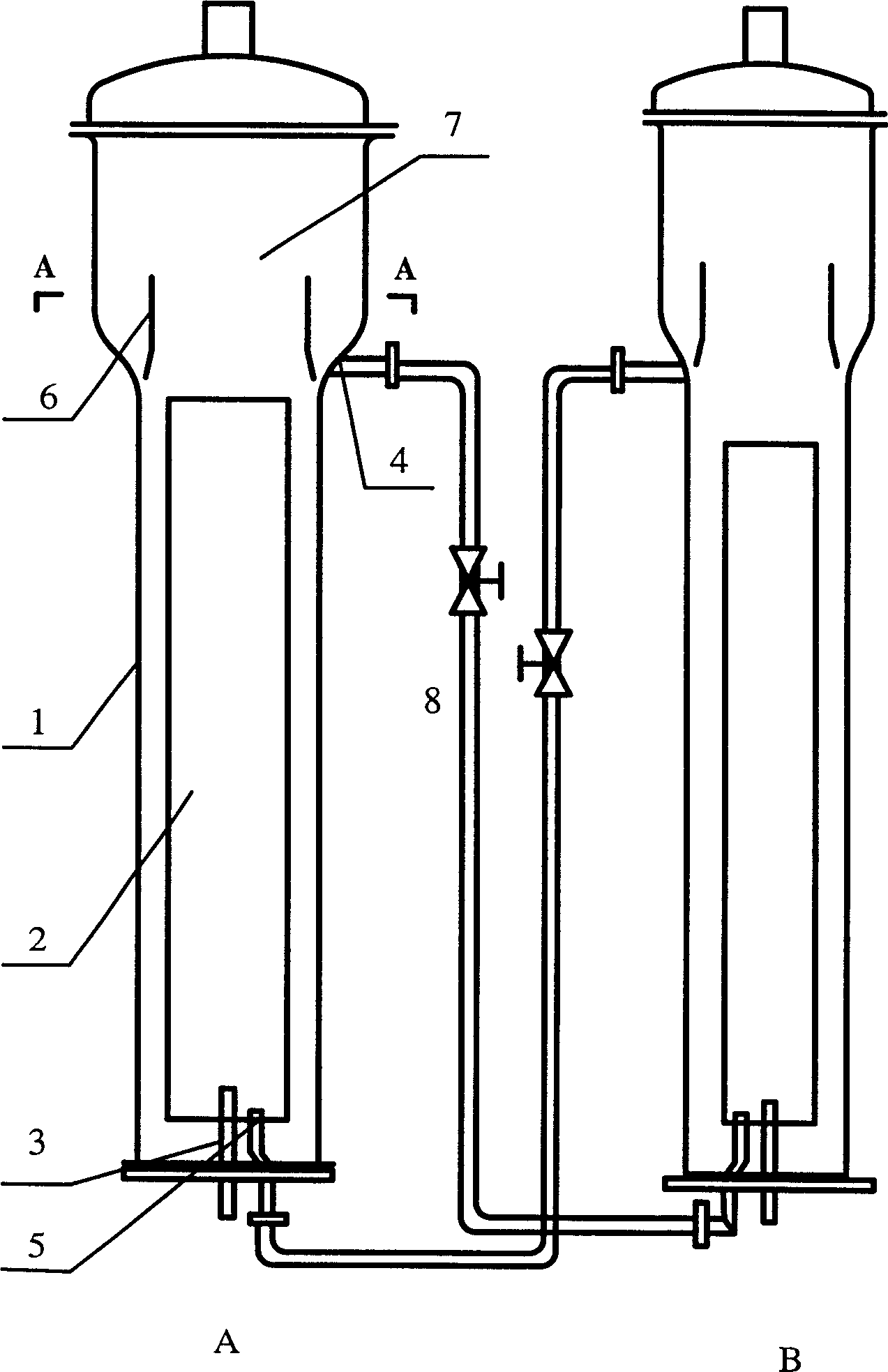

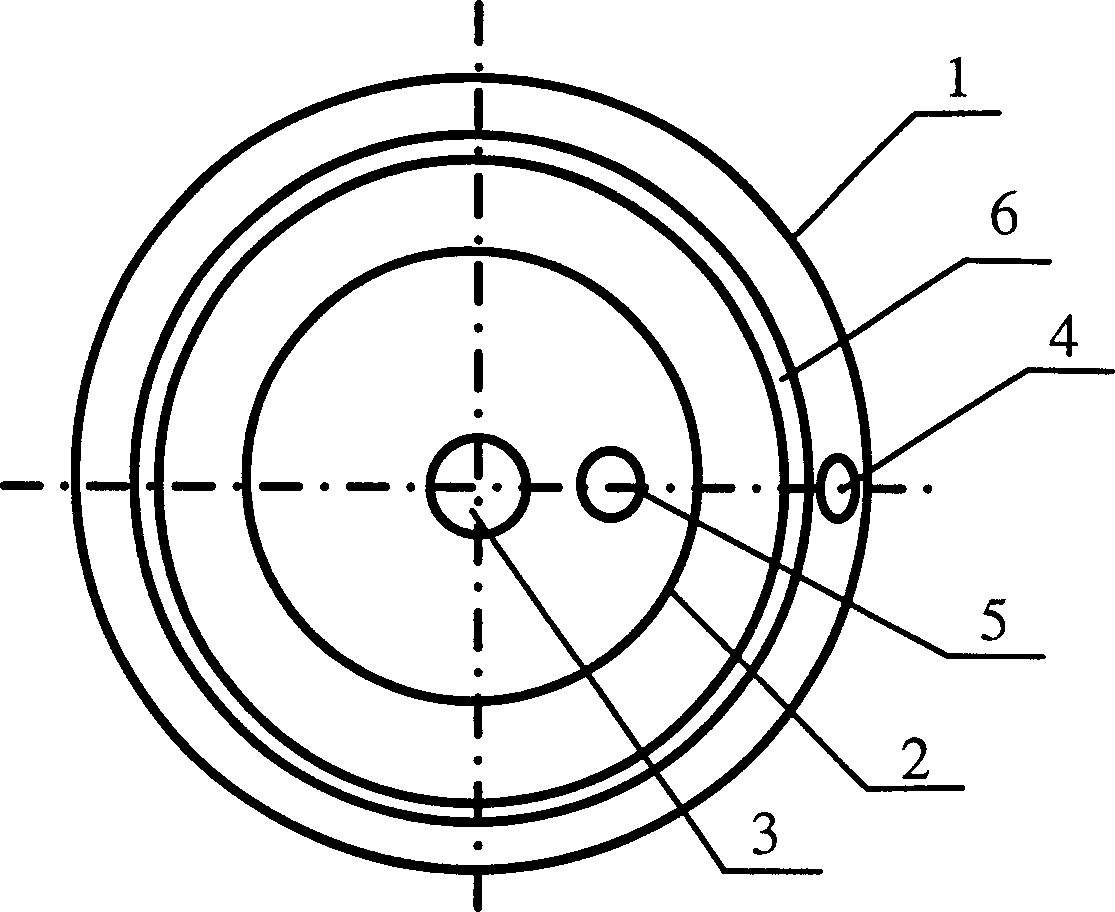

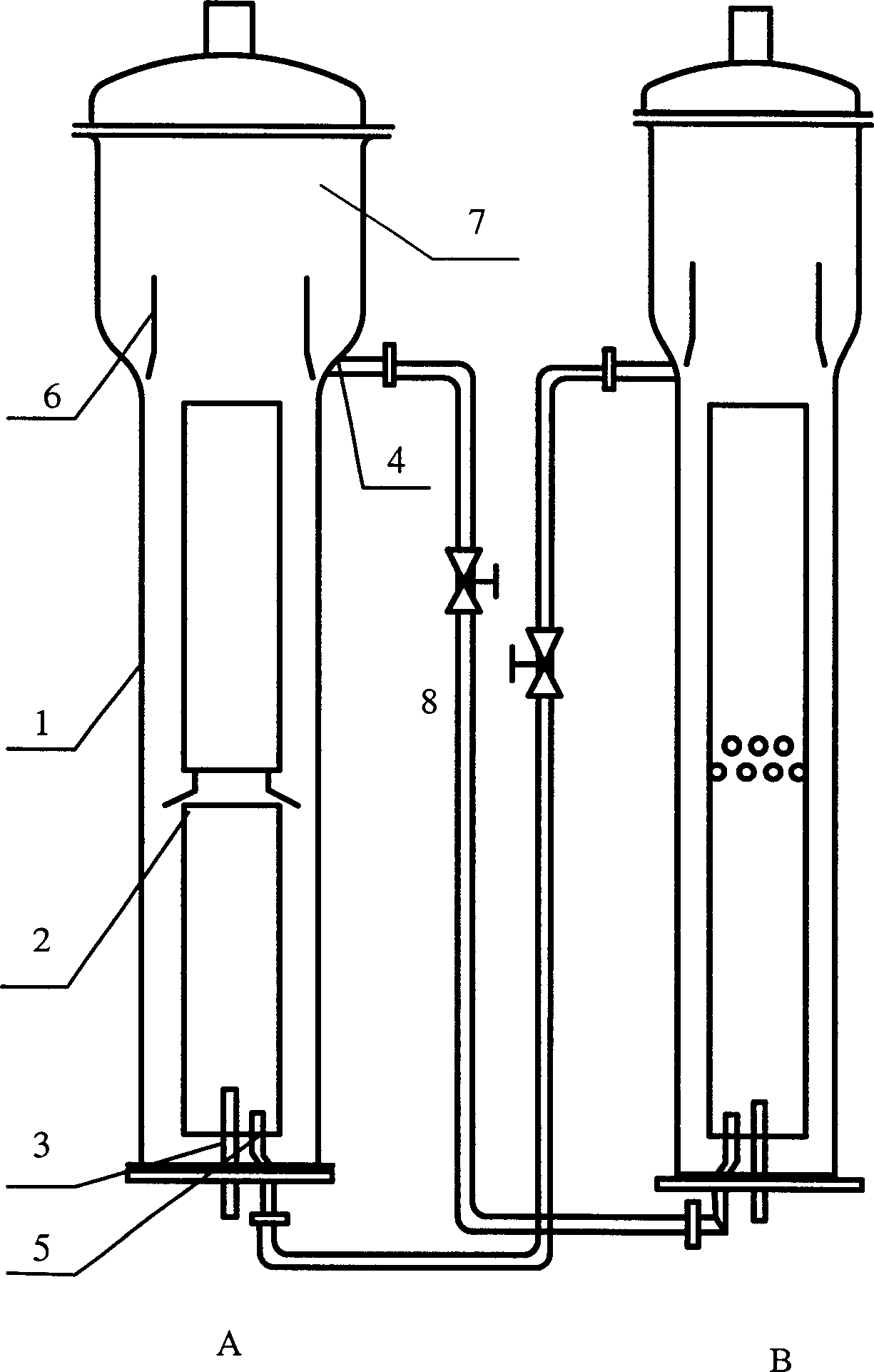

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: This embodiment is the change of the circulating fluid flow rate between the two reactors when the gas flow rate entering the reactor is different according to the experimental measurement. The draft tubes in the reactors tested in the experiment are all 2 levels. The main structural parameters of the reactor are listed in Table 1. The material of the reactor is plexiglass, and the material of the guide tube is stainless steel. The pipeline 8 is a nylon pipeline with a diameter of 2 cm, and a flow meter is arranged in the pipeline. The liquid used in the measurement is pure water, the gas is compressed air, and the operating pressure is normal pressure. When the volumetric gas holdup of gas in tower B remains constant (6%), and the volumetric gaseous holdup of gas in tower A ε A At different times, the flow rate L of the fluid flowing out of reactor B (fluid flowing into reactor A) B The changes are plotted in the attached Image 6 middle.

[0036] ...

Embodiment 2

[0037] Embodiment 2: This embodiment uses the reactor system of the present invention to remove hydrogen sulfide in the gas through absorption reaction and regenerate the absorbent. The process applies an iron-based process to complex Fe 3+ Catalyst for absorption reactions. Its absorption reaction and complexation of iron Fe 2+ The regeneration reaction is as follows:

[0038] The absorption reaction is:

[0039]

[0040] The regeneration reaction is:

[0041] Absorption reaction and regeneration reaction are carried out in loop reactor B of loop reactor A respectively. The hydrogen sulfide-containing gas enters the reactor A from the distributor of the reactor A, and is absorbed by the solution in A and complexed with Fe 3+ After the reaction, sulfur (S) and complexed Fe are generated 2+ ; The gas from which hydrogen sulfide is removed is discharged from the top of A. The complexed Fe formed in the reaction 2+ As the solution flows into reactor B, compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com