Method for making semiconductor laser and spot-size converter by double waveguide technology

A mode spot converter and laser technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of small process tolerance, deterioration of mode characteristics, and low reliability of devices, so as to reduce Auger recombination and reduce Noise index, the effect of reducing the number of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

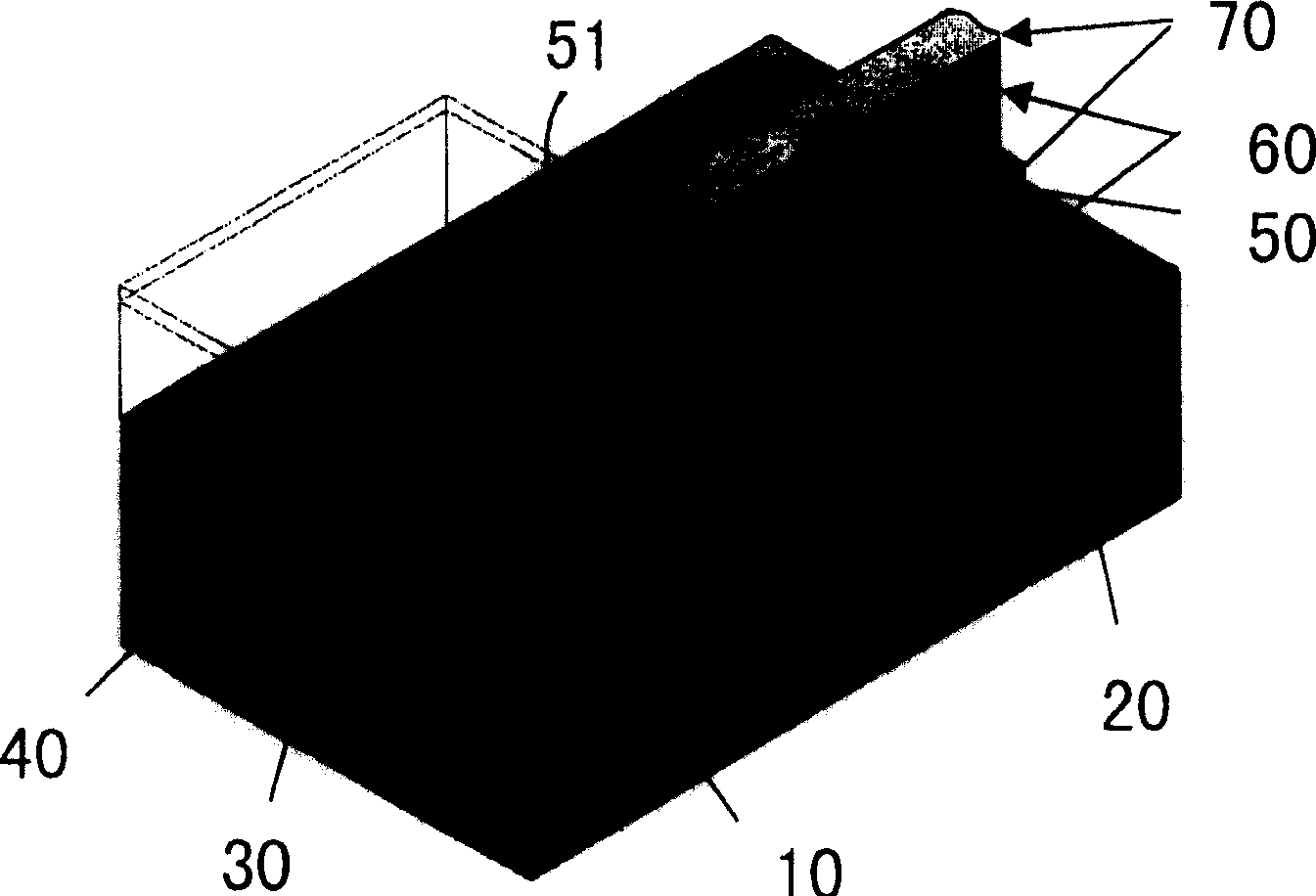

[0065] The invention relates to a novel method for making LD-SSC. It is characterized in that it comprises the following manufacturing steps:

[0066] (1) The 2-inch n-InP substrate undergoes strict decontamination (heating and boiling with ethanol, trichlorethylene, acetone, and ethanol in sequence) → pickling (soaking in concentrated sulfuric acid for 1 to 2 minutes) → water washing (rinsing with deionized water More than 50 times) → after drying treatment, put it into the growth chamber, the growth temperature is 655°C, the growth pressure is 22mbar, and the graphite boat speed is 75~80 rpm. The growth rate is 0.4~0.7nm / s.

[0067] (2) On the n-type indium phosphide substrate (100) epitaxially grow n-type indium phosphide buffer layer (0.5 μm thick), lower waveguide layer (thickness 50nm, bandgap wavelength 1.1 or 1.2 μm), 0.2 μm Indium phosphide space layer, lower optical confinement layer (thickness 80nm, bandgap wavelength 1.1 or 1.2μm), compressive strain active regio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bandgap wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com