Composite oil composition for film bearing

An oil film bearing, oil composition technology, applied in the direction of lubricating composition, etc., can solve the problems of affecting normal production, affecting anti-wear performance, wear and sintering, etc., and achieves improved anti-oxidation performance, low additive dosage, and excellent anti-oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The composite oil film bearing oil composition is prepared according to the following composition, and the total weight of the composition is 100%.

[0031] Amine and epoxy condensate (T1001) 0.05% by weight

[0032] Benzotriazole-aldehyde-amine condensate (T551) 0.53% by weight

[0033] Barium Dinonylnaphthalene Sulfonate (T705A) 0.15% by weight

[0034] Sulfurized Olefin Cottonseed Oil (T405A) 0.05% by weight

[0035] Sulfurized fatty acid ester (HD10) 0.69% by weight

[0036] Base oil (HVI500, viscosity at 40°C is 98mm 2 / s) margin

Embodiment 2

[0038] The composite oil film bearing oil composition is prepared according to the following composition, and the total weight of the composition is 100%.

[0039] Amine and epoxy condensate (T1001) 0.07% by weight

[0040] Benzotriazole fatty acid ammonium salt (T406) 0.55% by weight

[0041] Benzotriazole (T706) 0.43% by weight

[0042] Vulcanized cottonseed oil (T404) 0.12% by weight

[0043] Sulfurized isobutylene (T321) 0.49% by weight

[0044] Base oil (HVI650, viscosity at 40°C is 135mm 2 / s) margin

Embodiment 3

[0046] The composite oil film bearing oil composition is prepared according to the following composition, and the total weight of the composition is 100%.

[0047] Amine and epoxy condensate (T1001) 0.06% by weight

[0048] Thiadiazole polysulfide (T561) 0.20% by weight

[0049] Barium Dinonylnaphthalene Sulfonate (T705A) 0.15% by weight

[0050] Vulcanized cottonseed oil (T404) 0.07% by weight

[0051] Sulfurized fatty acid ester (HD10) 1.0% by weight

[0052] Base oil (HVI500:HVI650=6:4, viscosity at 40°C is 120mm 2 / s) margin

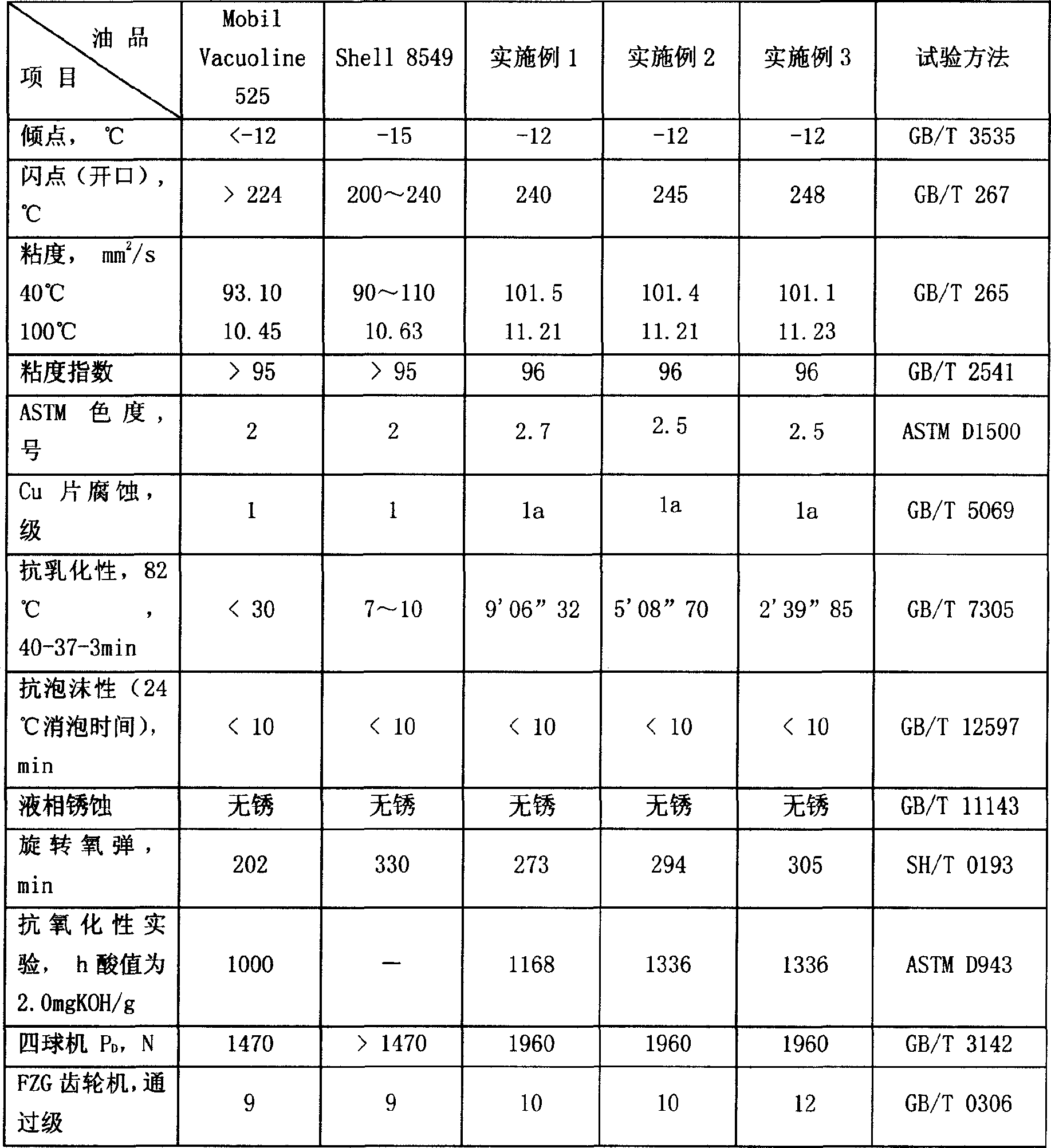

[0053] Table 1 is the performance index of the composite oil film bearing oil provided by the present invention and its comparison with commercially available products (Mobil Vacuoline 525 and Shell 8549). It can be seen from Table 1 that the composite oil film bearing oil composition provided by the present invention has excellent anti-oxidation, anti-wear, anti-emulsification, anti-rust and other properties.

[0054] Table 1 Comparison between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com