Hydrogen separation membrane and process for producing the same

A technology for hydrogen separation membranes and production methods, applied in the field of metal foils, capable of solving the problems of low ductility, reduced hydrogen permeability, lack of processability and durability of vanadium alloy foils and niobium alloy foils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

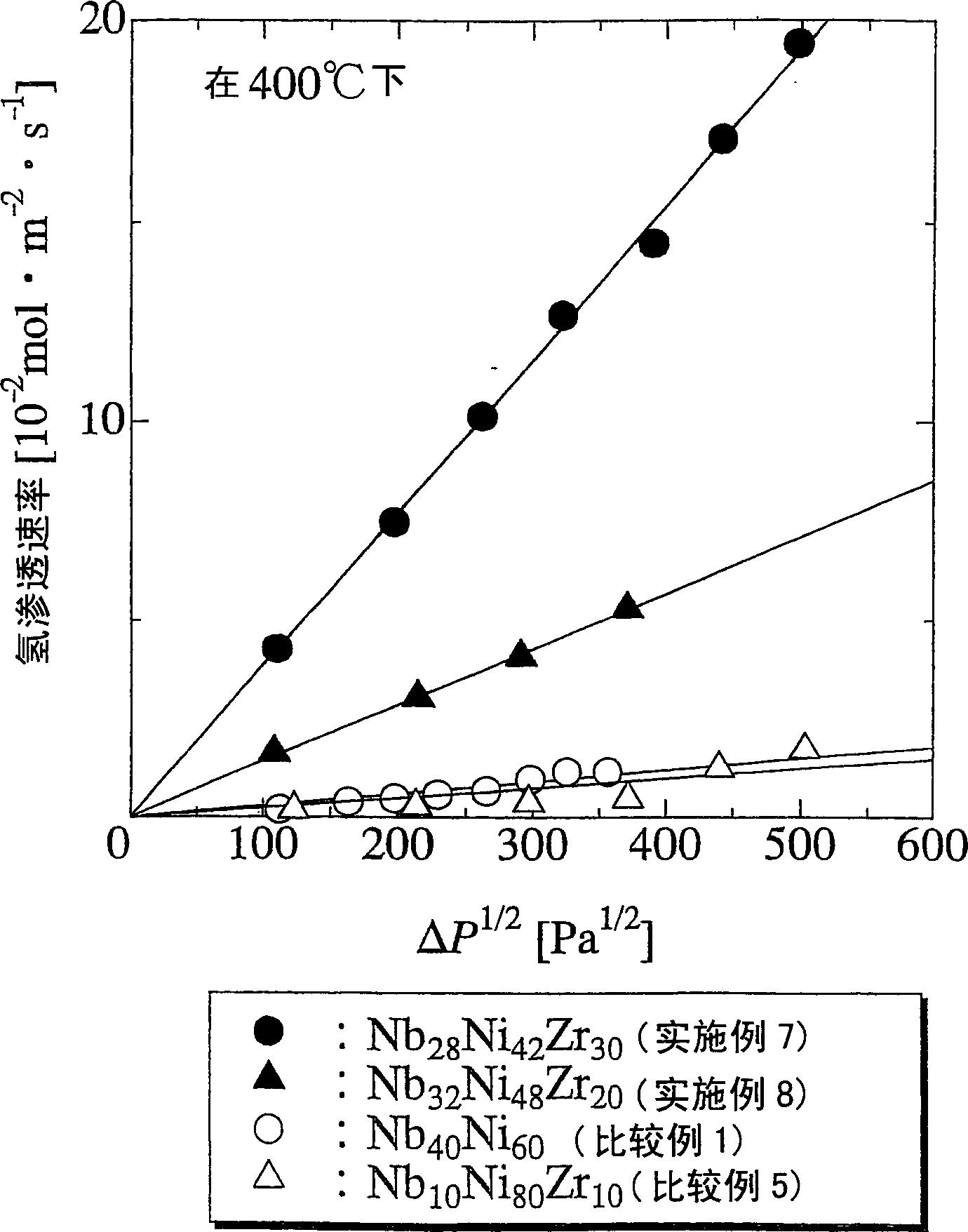

Examples

Embodiment

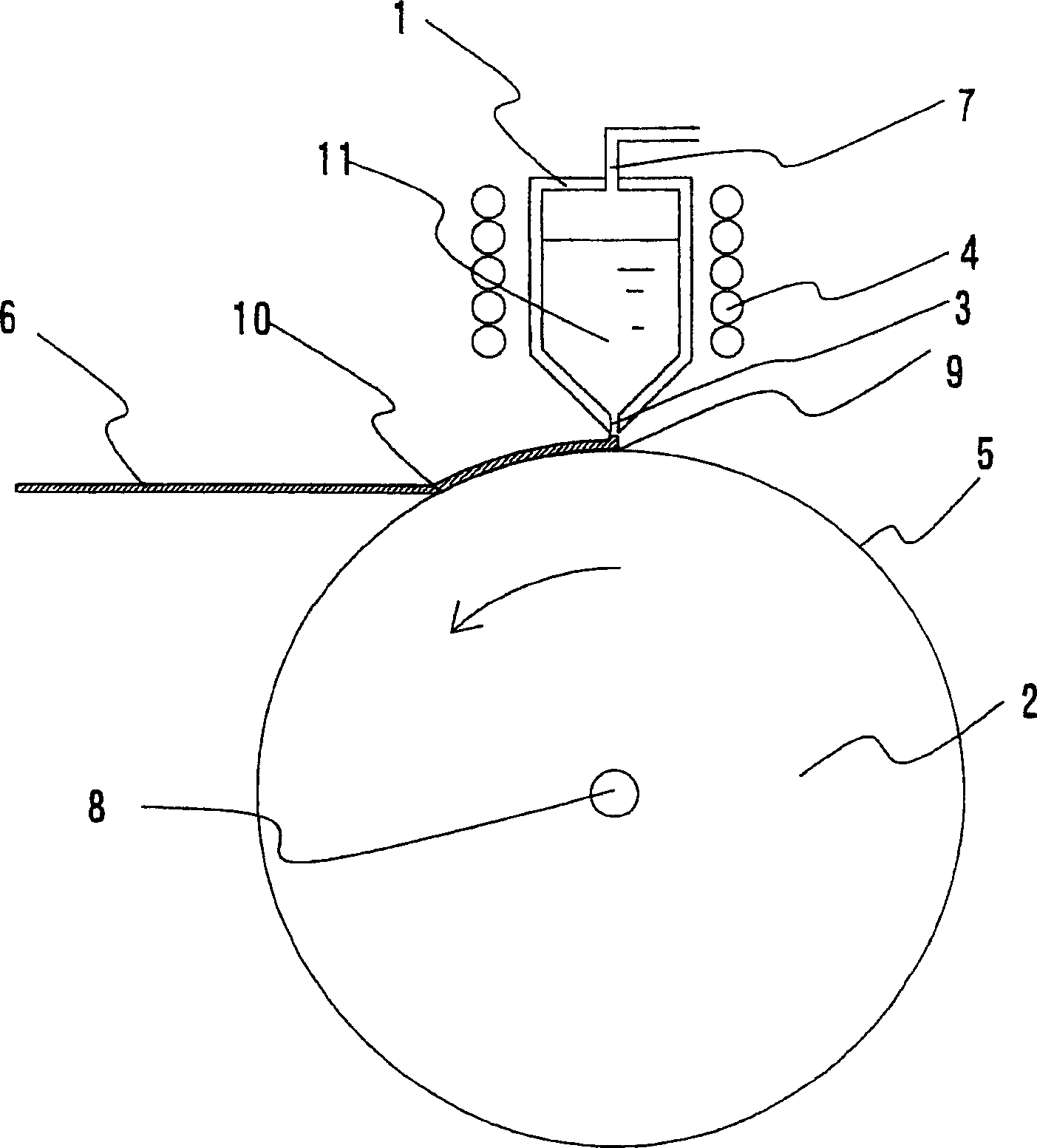

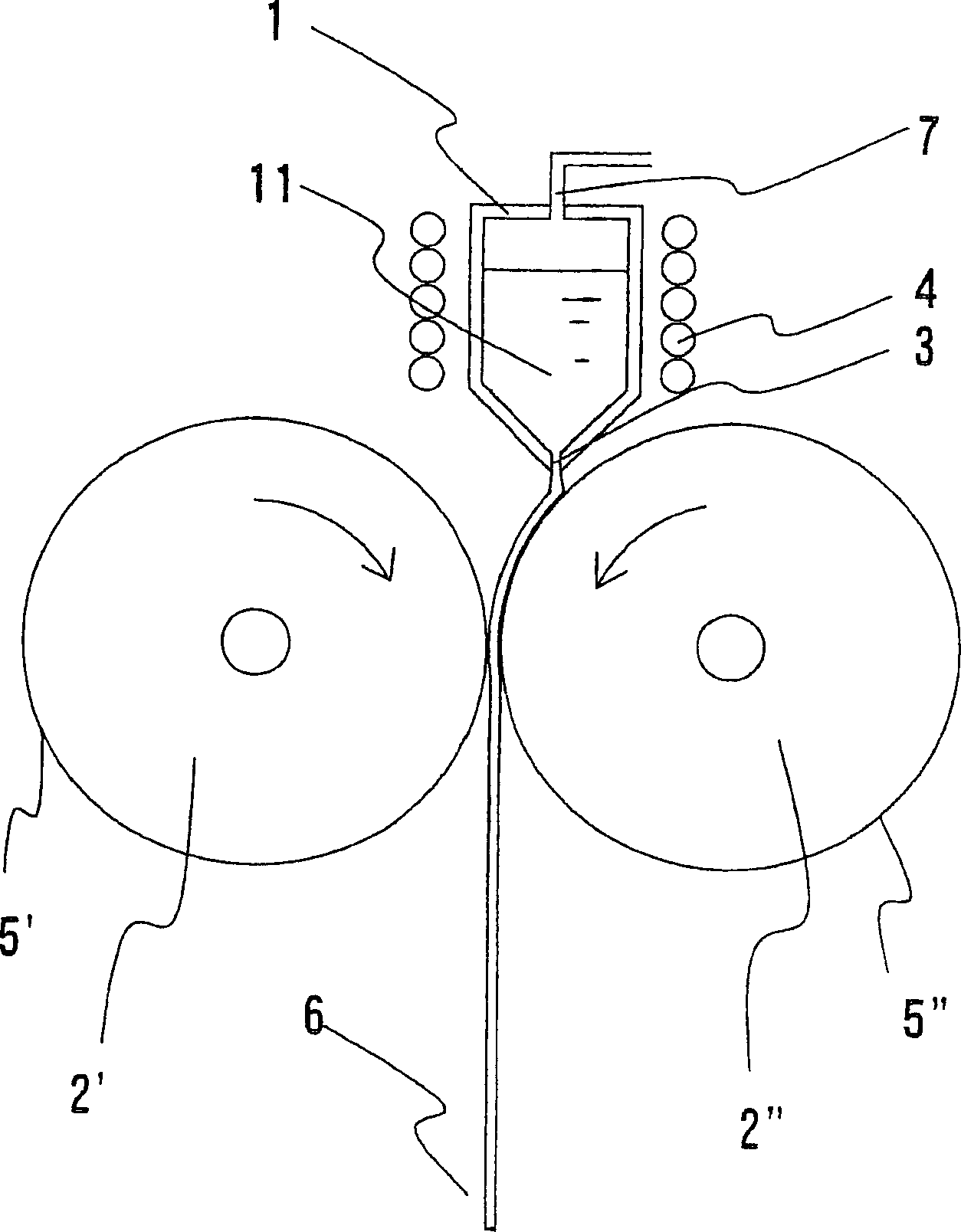

[0040] use has figure 1 The single-drum alloy foil production unit with the structure shown in the figure is used to manufacture niobium alloy foil.

[0041] The crucible 1 is made of boron nitride-based ceramics, and has a slit with a width of 0.4 mm and a length of 30 mm. The drum 2 is made of copper and has dimensions: a diameter of 300 mm and a length of 80 mm. The distance between the surface 5 of the drum and the slit 3 is 0.5 mm. Cool the tumbler with water. The number of rotations of the drum was set at 1500 rpm. A niobium alloy of 50Nb-40Ni-10Zr (atomic %) was placed in the crucible. The inside of the crucible is heated to 1750°C to completely melt the niobium alloy. Thereafter, argon gas was injected into the crucible so that the melt was ejected from the slit to form a foil layer on the surface of the drum, which was continuously peeled off from the drum so as to obtain a niobium alloy foil with a thickness of 0.03 mm (Example 1). The pressure inside the cruc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com