Nickel titanium niobium negative thermal expansion alloy and method of producing the same

A negative thermal expansion, nickel-titanium-niobium technology, applied in the field of alloys, can solve problems such as negative thermal expansion characteristics of metal materials, achieve good thermal shock resistance, and avoid deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

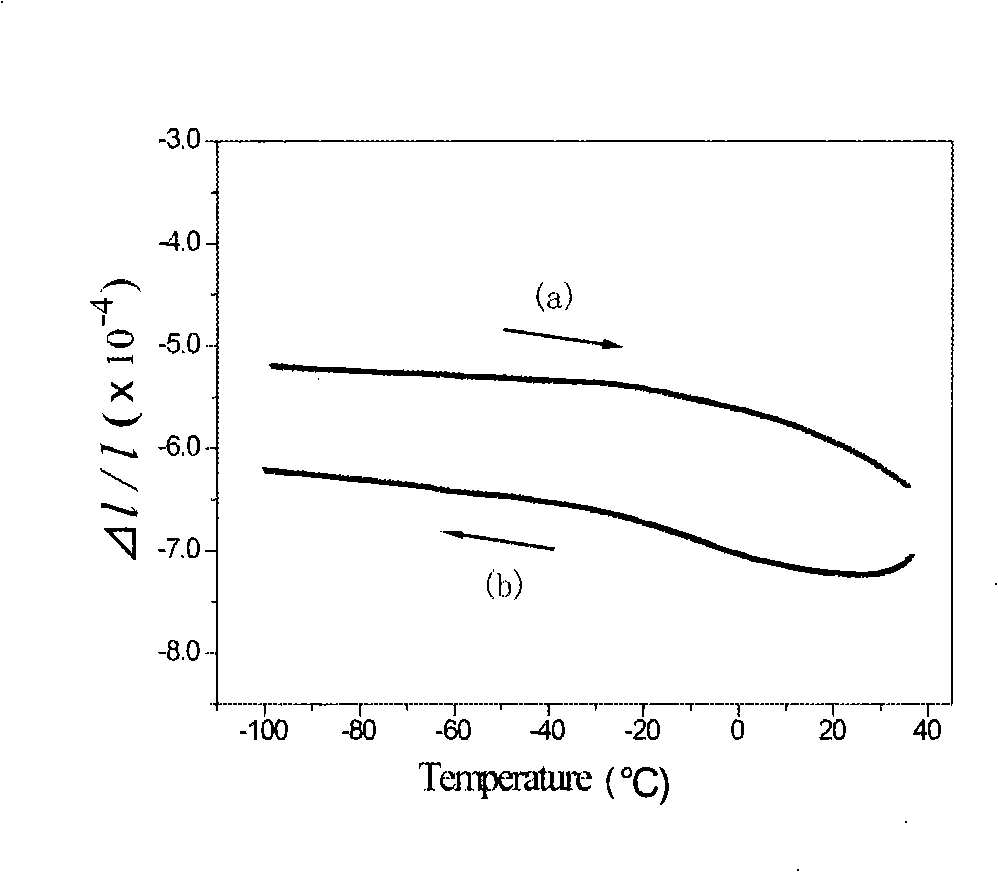

[0020] Example 1: Preparation of Ti with a reduction of 9% at room temperature 46.3 Ni 44.7 Nb 9 Cold rolled block

[0021] 46.3% titanium with a purity of 99.9%, 44.7% nickel with a purity of 99.5%, and 9% niobium with a purity of 99.9% were weighed. Put the above-mentioned titanium, nickel and niobium raw materials into a non-consumable vacuum electric arc furnace, and evacuate to 6×10 -3 Pa, filled with high-purity argon to 0.7×10 5 Pa, and then repeated smelting at 2800°C for 5 times to obtain a nickel-titanium-niobium negative thermal expansion alloy ingot. The nickel-titanium-niobium negative thermal expansion alloy ingot obtained above is hot-rolled at 850° C. into block shape. Cut the NiTiNb bulk alloy obtained above into plate shape by wire cutting method, put it into a vacuum heat treatment furnace for heat treatment, and the vacuum degree is 5×10 -3 Pa, after heat treatment at 850°C for 24 hours, cool in air. The alloy block was subjected to cold rolling in t...

Embodiment 2

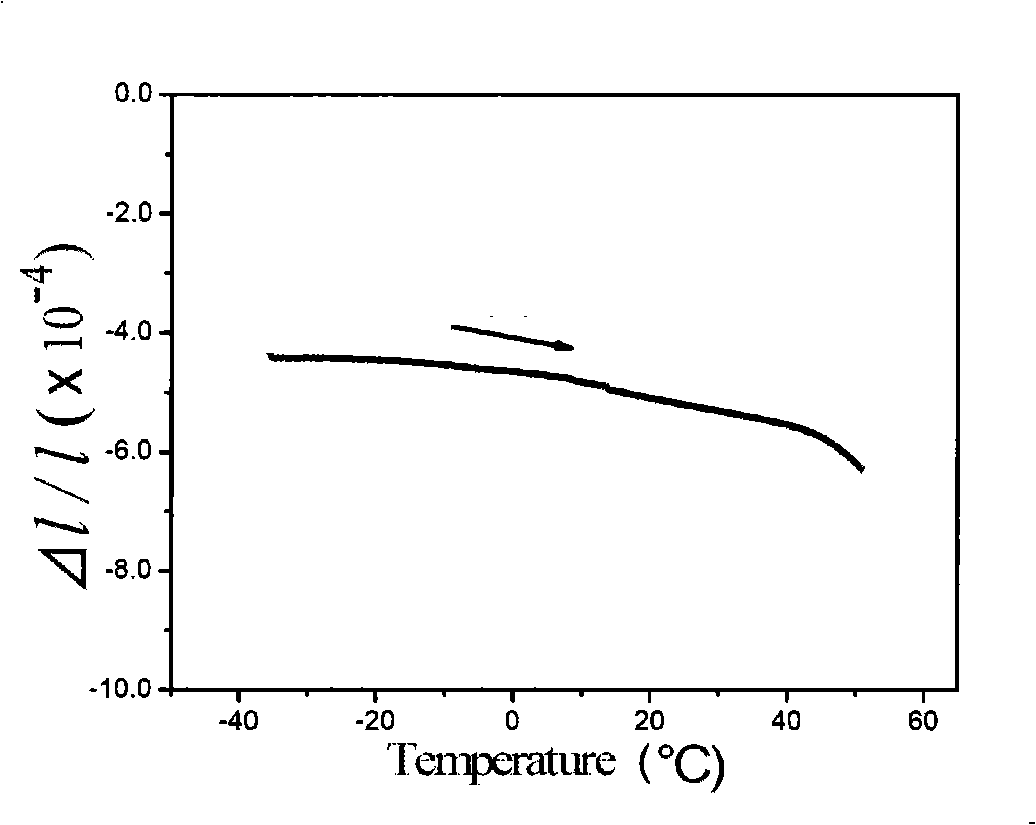

[0023] Example 2: Preparation of Ti with a reduction of 7% at liquid nitrogen temperature 44 Ni 47 Nb 9 Cold rolled block

[0024] 44% titanium with a purity of 99.9%, 47% nickel with a purity of 99.5%, and 9% niobium with a purity of 99.9% were weighed. Put the above-mentioned titanium, nickel and niobium raw materials into a non-consumable vacuum electric arc furnace, and evacuate to 3×10 -3 Pa, filled with high-purity argon to 0.6×10 5 Pa, and then repeated smelting at 2500°C for 6 times to obtain a nickel-titanium-niobium negative thermal expansion alloy ingot. The nickel-titanium-niobium negative thermal expansion alloy ingot obtained above is hot-rolled at a temperature of 950° C. into a block. Cut the NiTiNb bulk alloy obtained above into plate shape by wire cutting method, put it into a vacuum heat treatment furnace for heat treatment, and the vacuum degree is 4×10 -3 Pa, after heat treatment at 950°C for 24 hours, cool in air. The alloy block is subjected to co...

Embodiment 3

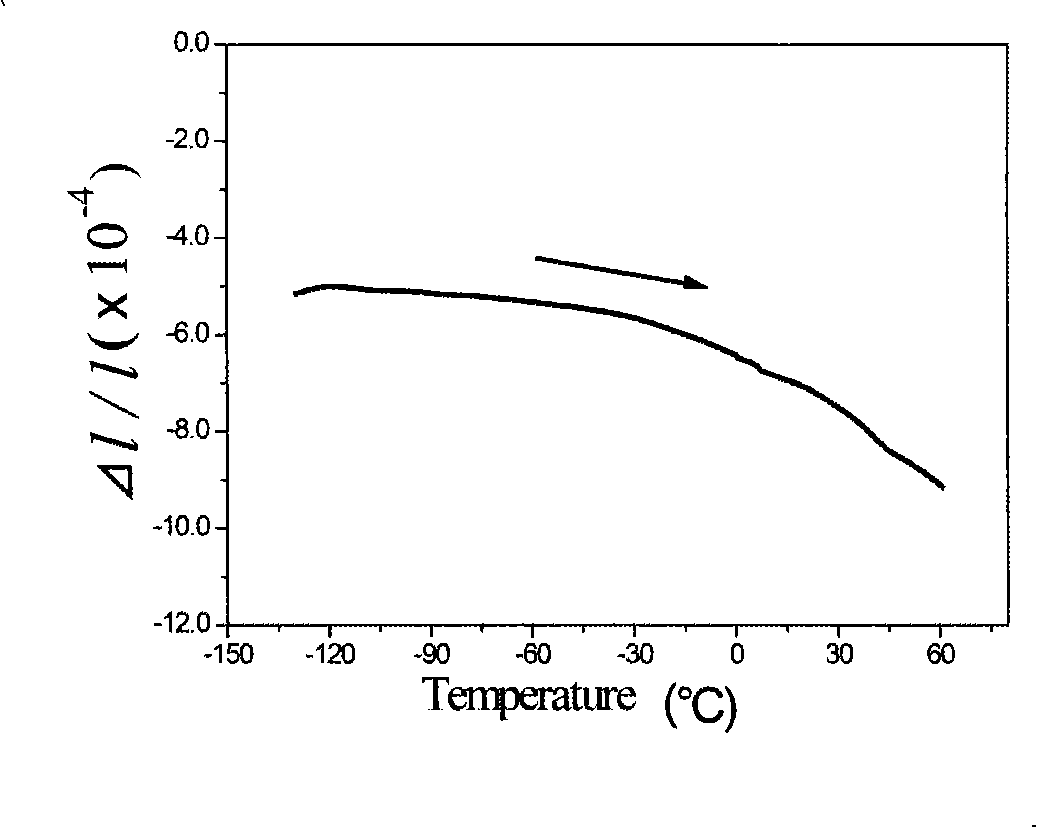

[0026] Example 3: Preparation of Ti with a reduction of 3% at room temperature 42 Ni 40 Nb 18 Cold rolled block

[0027] 42% titanium with a purity of 99.9%, 40% nickel with a purity of 99.5%, and 18% niobium with a purity of 99.9% were weighed. Put the above-mentioned titanium, nickel and niobium raw materials into a non-consumable vacuum electric arc furnace, and evacuate to 5×10 -3 Pa, filled with high-purity argon to 0.6×10 5 Pa, and then repeated smelting at 2700°C for 6 times to obtain a nickel-titanium-niobium negative thermal expansion alloy ingot. The nickel-titanium-niobium negative thermal expansion alloy ingot obtained above is hot-rolled at a temperature of 900° C. into a block. Cut the NiTiNb bulk alloy obtained above into plate shape by wire cutting method, put it into a vacuum heat treatment furnace for heat treatment, and the vacuum degree is 2×10 -3 Pa, after heat treatment at 900°C for 48 hours, cool in air. The alloy block was subjected to cold rolli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com