Cerium doping zirconium tungstate negative heat expansion conductive ceramic powder and preparation method thereof

A technology of negative thermal expansion and conductive ceramics, applied in the direction of non-metallic conductors, etc., can solve the problems of low purity of zirconium tungstate-based compounds, high reaction temperature, and difficult doping, so as to avoid high-temperature sintering procedures, simplify the synthesis process, and sample The effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

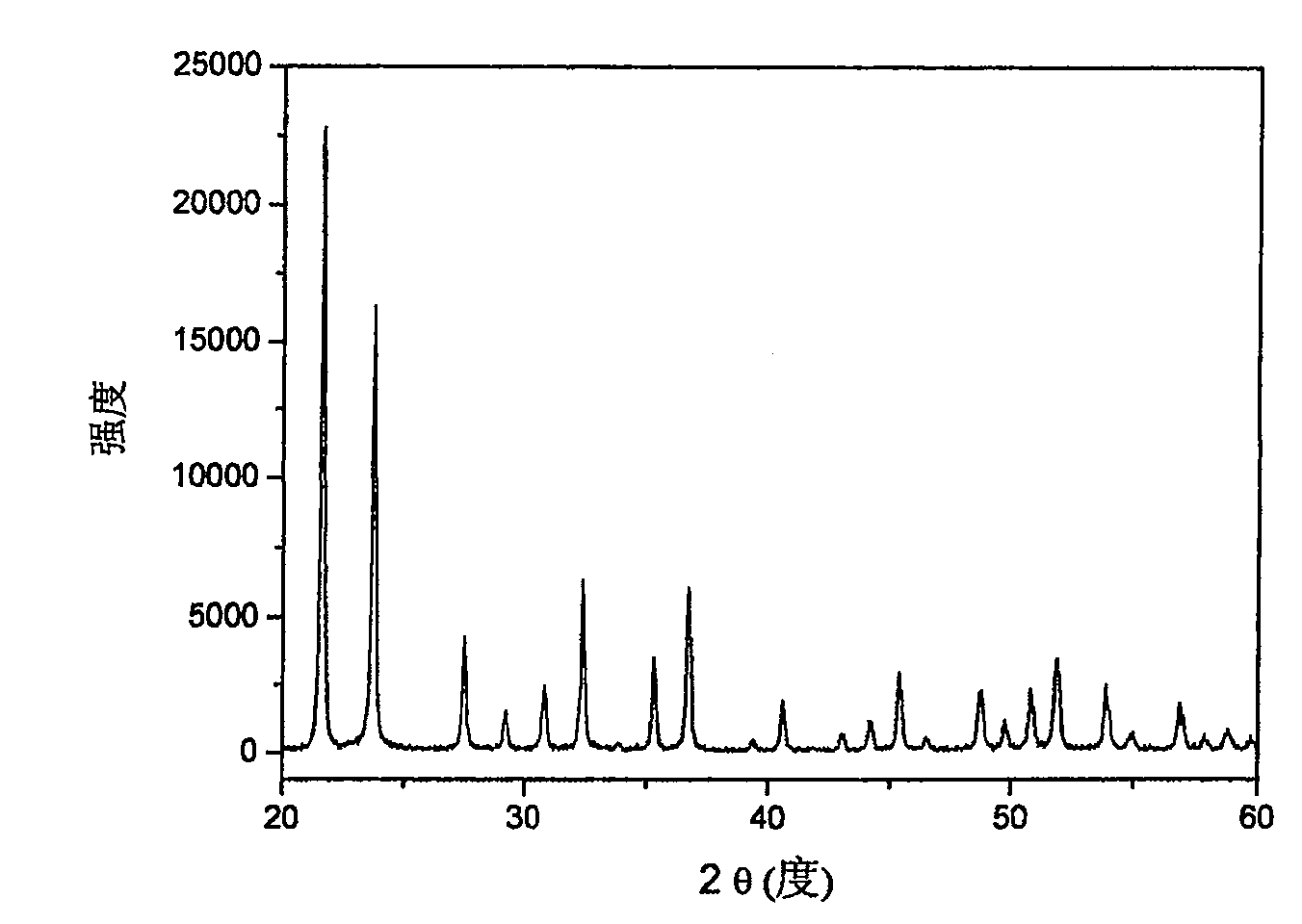

Image

Examples

Embodiment 1

[0017] Using this invention to synthesize Zr 0.99 Ce 0.01 W 2 o 8 . Weigh 2.7129 grams of ZrOCl 2 ·8H 2 O, 4.4418 g 5 (NH 4 ) 2 O·12WO 3 ·5H 2 O and 0.0468 g (NH 4 ) 2 Ce(NO 3 )6 as raw material. ZrOCl 2 ·8H 2 O and (NH4) 2 Ce(NO 3 ) 6 mixed and dissolved in deionized water to make Ce 4+ and Zr 4+ The sum of the concentrations is 0.1mol L -1 , 5(NH 4 ) 2 O·12WO 3 ·5H 2 O is also dissolved in deionized water, so that the W in the solution 6+ The concentration is also 0.1mol L -1 . Mix deionized water and concentrated hydrochloric acid to a concentration of 6mol L -1 hydrochloric acid solution for use. ZrOCl was added by double drop method 2 and (NH4) 2 Ce(NO 3 ) 6 mixed solution of 5(NH 4 ) 2 O·12WO 3 ·5H 2 The O solution was added to 25ml of deionized water, stirred while adding dropwise, and the temperature of the mixed solution was controlled at 60° C. and stirred for 4 hours. Next, raise the temperature of the mixture to 80°C, and add 6 ...

Embodiment 2

[0020] Using this invention to synthesize Zr 0.98 Ce 0.02 W 2 o 8 . Weigh 2.6855 grams of ZrOCl 2 ·8H 2 O, 4.4418 g 5 (NH 4 ) 2 O·12WO 3 ·5H 2 O and 0.0936 g (NH4) 2 Ce(NO 3 ) 6 as raw material. ZrOCl 2 ·8H 2 O and (NH4) 2 Ce(NO 3 ) 6 mixed and dissolved in deionized water to make Ce 4+ and Zr 4+ The sum of the concentration is 0.4mol L -1 , 5(NH 4 ) 2 O·12WO 3 ·5H 2 O is also dissolved in deionized water, so that the W in the solution 6+ The concentration is also 0.4mol L -1 . Mix deionized water and concentrated hydrochloric acid to prepare a concentration of 10mol L -1 hydrochloric acid solution for use. ZrOCl was added by double drop method 2 and (NH4) 2 Ce(NO 3 ) 6 mixed solution of 5(NH 4 ) 2 O·12WO 3 ·5H 2 The O solution was added to 50ml of deionized water, stirred while adding dropwise, and the temperature of the mixed solution was controlled at 80°C and stirred for 8h. Next, raise the temperature of the mixture to 90°C, and add 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com