Polymer using methyl methacrylate as main component

A technology of methyl methacrylate and polymers, applied in the field of polymers, can solve the problems of difficult production and high cost, and achieve the effects of high upper limit temperature, good thermal cracking resistance and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

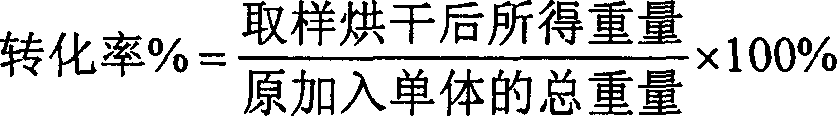

Method used

Image

Examples

Embodiment 1

[0057] Using methyl methacrylate monomer as a reactive monomer, it was purified twice by vacuum distillation, and then stored below 5°C.

[0058] Get 100 milliliters (0.93 moles) of purified methyl methacrylate monomer, 0.02 grams (0.00012 moles) of 2,2'-azobisisobutyronitrile, 2.0 grams (0.018 moles) of ε-caprolactam, and N-dodecyl mercaptan 0.05 gram (0.00025 mole), (the mol ratio=0.49:1 of above-mentioned free radical starter and mercaptan compound; The mol ratio=72 of lactam compound and mercaptan compound: 1; and the molar ratio of mercaptan compound and free radical polymerizable monomer=0.027:100), under nitrogen atmosphere, add in the glass reactor with stirring device, start timing to carry out polymerization reaction, wherein above-mentioned glass reactor has been Put it in a water tank in advance, the temperature of the water bath is 90°C, and take samples at intervals after the polymerization starts, add methanol immediately after sampling to stop the reaction, pre...

Embodiment 2

[0061] Same as in Example 1, the amount of each component used is 100 milliliters (0.93 moles) of methyl methacrylate monomer, 0.05 grams (0.00020 moles) of 2,2'-azobis(2,4-dimethylvaleronitrile) ), n-dodecyl mercaptan 0.12 gram (0.00059 mole), ε-caprolactam 5.0 gram (0.044 mole), water bath temperature is 70 ℃, the data of conversion rate and molecular weight are shown in Table 2. In addition, the glass transition temperature of the dried product with a reaction time of 60 minutes was 124°C, the temperature for 5% weight loss was 335°C, and the syndiotactic structure content was 58% by mole.

[0062] time (minutes)

Embodiment 3

[0064] Same as in Example 1, the amount of each component used is 100 milliliters (0.93 moles) of methyl methacrylate monomer, 0.03 grams (0.00020 moles) of 2,2'-azobis(2,4-dimethylvaleronitrile) ), n-dodecyl mercaptan 0.07 gram (0.00035 mole), 2-pyrrolidone 3 grams (0.035 mole), water bath temperature is 80 ℃, the data of conversion rate and molecular weight are as table 3. In addition, the glass transition temperature of the dried product with a reaction time of 70 minutes was 125° C., the temperature of 5% weight loss was 335° C., and the syndiotactic structure content was 59 mol%.

[0065] time (minutes)

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com