Polishing method for inner surface of tubular brittle material and material obtained by the method

A brittle material, inner surface technology, used in grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, grinders, etc., can solve the problems of high cost, large wear, and low polishing ability of cerium oxide paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

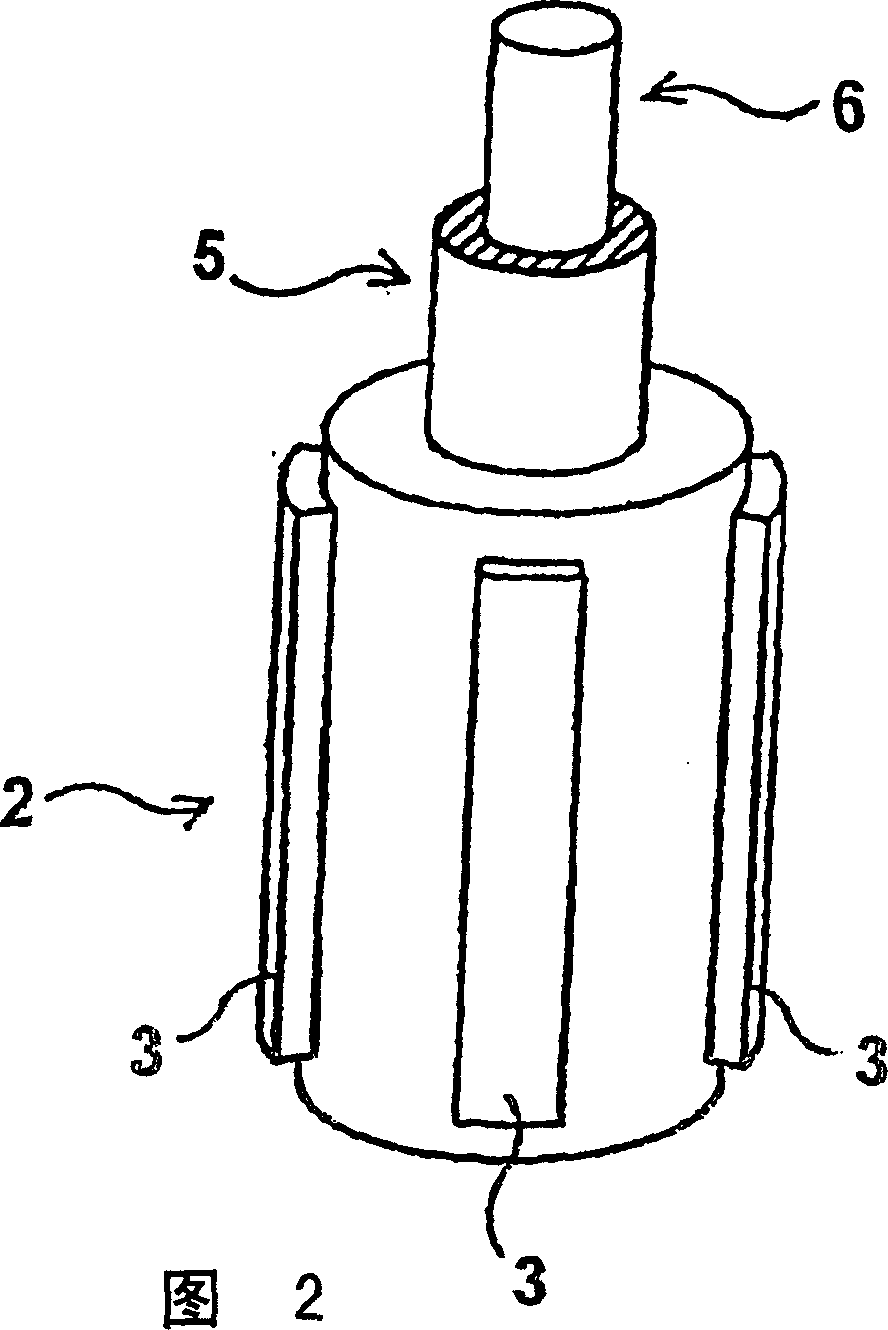

[0021] Silicon tetrachloride is vaporized, and the thus vaporized silicon tetrachloride is then subjected to flame hydrolysis in an acidic hydrogen flame, followed by deposition of fine particles of quartz glass on the surrounding area of the rotating substrate. A large-sized porous soot body is obtained according to the OVD method. The thus-prepared porous soot body was placed in an electric furnace, taking into account the refractive index of the glass mandrel and similar conditions, from He and Cl 2 The mixed gas was heated to 1100°C for dehydration, and then transformed into transparent glass by heating to 1600°C in a He atmosphere to produce a cylindrical quartz glass blank. The two ends of the cylindrical quartz glass blank thus produced are cut, and its inside is ground with a vertical honing machine having a cylindrical polishing head as shown in FIG. 2 with an enlarged portion 3 (machine honing grinding), the enlarged portion is evenly distributed around the surfac...

example 2

[0024] Polishing-finishing was performed in the same manner as in Example 1, except that the diamond paper 4 was attached only to the four enlarged portions 3 evenly distributed around the polishing head 4 (machine honing). The maximum roughness Rmax and the centerline average roughness Ra of the inner surface of the obtained quartz glass tube are approximately the same as the data of Example 1; but a spiral scratch is observed, which may be made of ground stone or quartz glass debris As a result, debris gets lodged and scratches the inner surface. Therefore, this result is acceptable only for low quality requirements, and this is not the best mode of implementing the method according to the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com