Method for manufacturing semi-transparent semi-reflective electrode substrate, reflective element substrate, method for manufacturing same, etching composition used for the method for manufacturing th

A semi-transmissive, semi-reflective, electrode substrate technology, applied in the field of etching solution, can solve the problems of complex manufacturing process, difficult viewing, different viewing methods, etc., and achieve the effect of shortening the manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

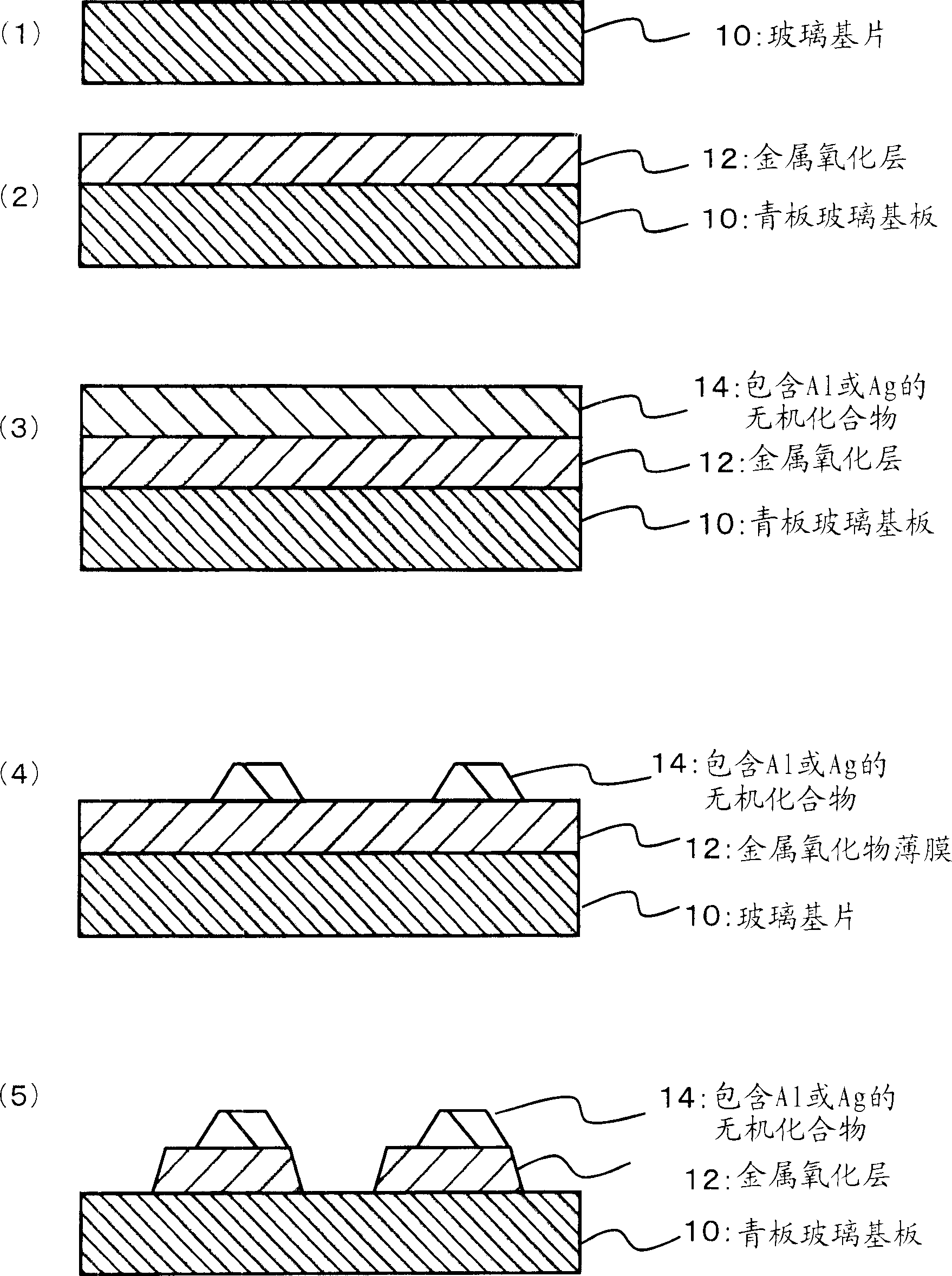

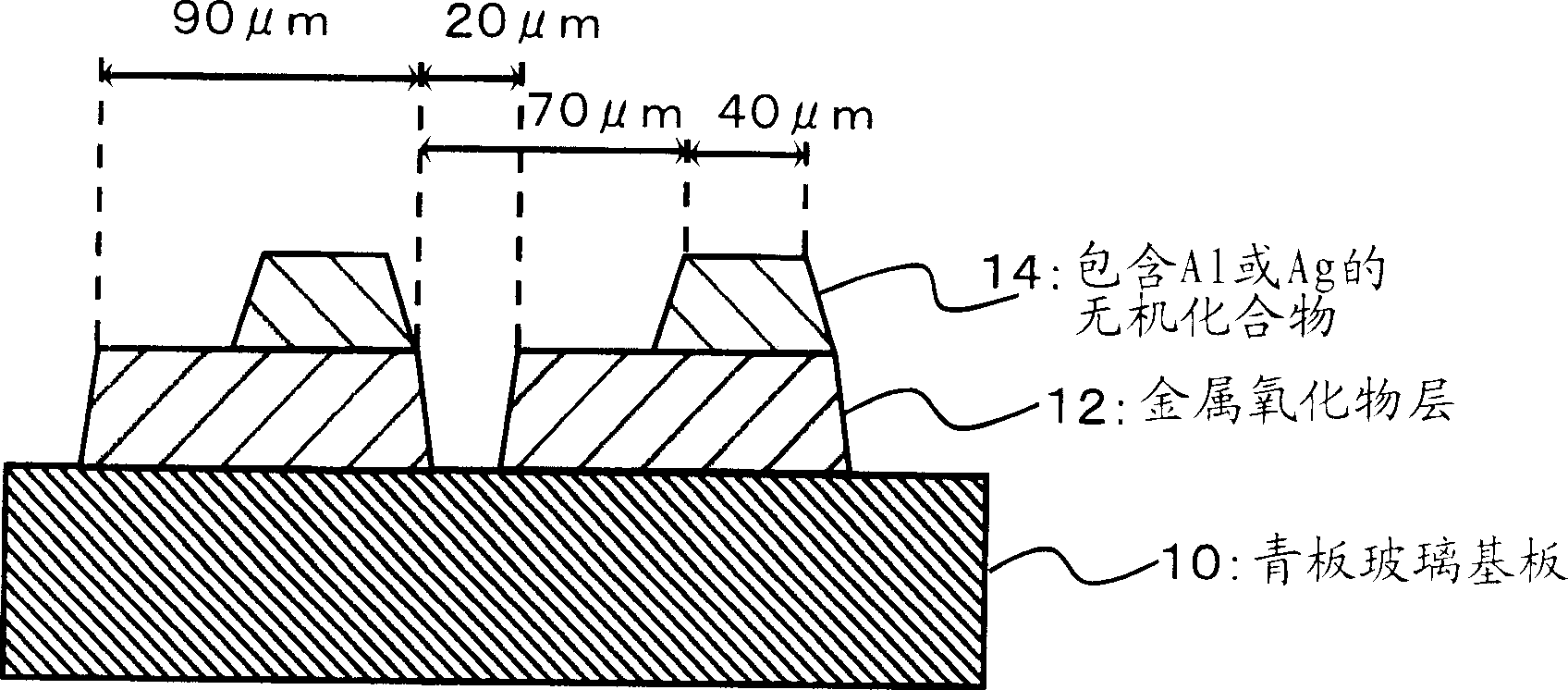

[0142] First, the metal oxide layer 12 is coated with SiO 2 The blue plate glass (soda lime glass) substrate 10 (refer to figure 1 (1)) on the film. The status is shown in figure 1 (2). In addition, in forming the metal oxide layer 12, a DC magnetron sputtering apparatus (manufactured by Shinko Seiki Co., Ltd.) was used.

[0143] In addition, the temperature of the blue glass substrate 10 at the time of film formation was 200 degreeC. In addition, the film thickness of the formed metal oxide layer 12 was 75 nm, and the resistivity was 380 μΩcm.

[0144] Next, the inorganic compound layer 14 was formed on the metal oxide layer 12 using a target Ag composed of Ag—Pd—Cu (98.5:0.5:1.0% by weight). In addition, the film thickness of the inorganic compound layer 14 was 100 nm. Its form is shown in figure 1 (3). In addition, the metal oxide layer 12 and the inorganic compound layer 14 mainly composed of Ag are referred to as an electrode layer. In addition, in Figure 1~...

Embodiment 1-2

[0157] A second target comprising indium oxide-tin oxide-cerium oxide (In / (In+Sn)=90 atomic%, Ce / (In+Sn+Ce)=4.9 atomic%) was used instead of the target used in Example 1-1. first target. In addition, Ag-Au-Ni (98.5:0.5:1.0 wt%) was used instead of Ag-Pd-Cu (98.5:0.5:1.0 wt%) used in Example 1-1. Other than that, it carried out by the same method as Example 1-1. That is, film formation of the first metal oxide layer 12 a and the inorganic compound layer 14 is performed. This form is shown in figure 2 (1) ~ (3). Furthermore, the first metal oxide layer 12a formed in the present embodiment 1-2, that is, as figure 2 The first metal oxide layer 12a shown in (2) is and figure 1 The metal oxide layer 12 shown in (2) is the same metal oxide layer.

[0158] Next, the second metal oxide layer 16 was formed using a third target containing indium oxide+zinc oxide (In / (In+Zn)=75 atomic %) as a protective film. In addition, the temperature at the time of film formation was room te...

Embodiment 1-3

[0164] A fourth target of indium oxide-tin oxide-praseodymium oxide (In / (In+Sn)=90 atomic%, Pr / (In+Sn+Pr)=4.6 atomic%) was used instead of the one used in Example 1-1 first target. Other than that, the metal oxide layer 12 and the inorganic compound layer 14 were formed in the same manner as in Example 1-1.

[0165] Next, etching was performed in the same manner as in Example 1-1 to manufacture a transflective electrode substrate. The resistivity of the metal oxide layer 12 was 450 μΩcm. This form is shown in figure 1 (1)~(5) of.

[0166] The thus obtained semi-transmissive and semi-reflective electrode substrate can achieve low resistance. In addition, when the substrate surface was observed with a scanning electron microscope, the surface roughness of the metal oxide layer 12 was not observed. In addition, almost no change was seen in the edge portion of the inorganic compound layer 14 before and after etching with oxalic acid. This means that the etchant σ of oxalic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com