Surface treated metal board

A surface treatment and metal plate technology, which is applied in the direction of metal layered products, metal material coating technology, and the device for coating liquid on the surface, can solve the problems of poor corrosion resistance and improve corrosion resistance and conductivity Excellent, excellent alkali resistance and degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] (5) Preparation method of resin aqueous solution and formation method of resin film

[0075] The aqueous resin liquid used in the present invention may contain diluting solvents, anti-skinning agents, leveling agents, defoamers, penetrating agents, emulsifiers, film-forming aids, coloring pigments, Thickeners and lubricants etc. The preparation method of the above-mentioned resin aqueous liquid is not particularly limited, and the above-mentioned carboxyl-containing polyurethane aqueous liquid, ethylene-unsaturated carboxylic acid copolymer aqueous dispersion, silica particles, silane coupling agent, and Necessary, wax, cross-linking agent etc. are obtained above-mentioned resin water-based liquid. Silica particles, silane coupling agent, wax, crosslinking agent, etc. can be added at any stage, but it is desirable not to heat in order to prevent crosslinking reaction and gelation after adding the crosslinking agent and silane coupling agent.

[0076] In order to form ...

Embodiment

[0081] [Evaluation method]

[0082] (1) Corrosion resistance

[0083] The obtained surface-treated metal sheet (resin-coated steel sheet) was subjected to a salt spray test on an edge-sealed flat sheet in accordance with JIS-Z2371, and the time until 1% of white rust occurred was evaluated.

[0084] (evaluation criteria)

[0085] ◎: white rust occurred greater than or equal to 240 hours

[0086] ○: White rust occurs more than or equal to 120 hours to less than 240 hours

[0087] △: White rust occurred greater than or equal to 72 hours to less than 120 hours

[0088] ×: White rust occurred in less than 72 hours

[0089] (2) Abrasion resistance

[0090] The obtained surface-treated metal sheet (resin-coated steel sheet) was subjected to a vibration test in accordance with the Packaging-Vibration Test (JIS-Z0232) standard, and the appearance of the test material after a predetermined time was evaluated based on the following criteria. As a vibration test device, a product n...

experiment example 1

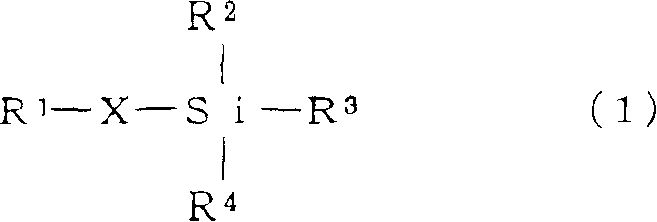

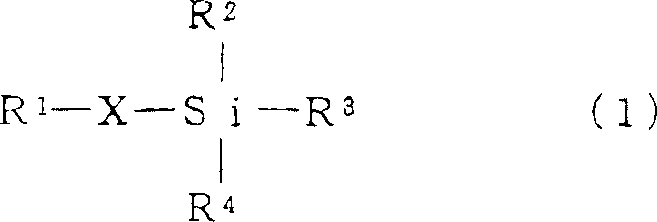

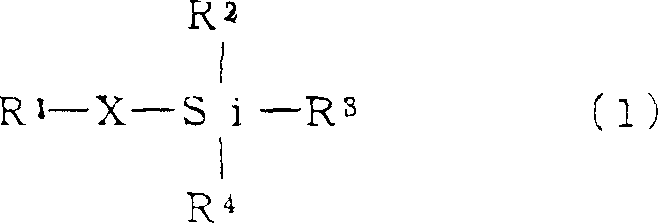

[0123] The carboxyl group-containing polyurethane resin aqueous solution obtained above, the above-mentioned ethylene-acrylic acid copolymer aqueous dispersion, and silica particles (Nissan Chemical Snow-Tex XS, average particle diameter: 4 to 6 nm) were added to 100 in terms of non-volatile components. Parts by mass were blended to achieve the blending ratio shown in Table 1. With respect to the total of 100 parts by mass, 15 parts by mass of γ-glycidoxypropyltrimethoxysilane (KBM403 manufactured by Shin-Etsu Chemical Co., Ltd.) was further added as a silane coupling agent, Made into resin water-based liquid.

[0124]Use a roller to coat the resin aqueous solution on the surface of the electroplated pure zinc steel plate, heat and dry it at a plate temperature of 90°C, and obtain an adhesion amount of 0.4g / m 2 Resin-coated metal sheets (resin-coated steel sheets). Table 1 shows the evaluation results of the obtained resin-coated steel sheets in terms of corrosion resistance,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com