Technological process of making ferrous metal surface anticorrosive, antiwear, antishock and insulating

A technology of ferrous metals and process methods, which is applied in the field of surface treatment of ferrous metal surfaces, can solve problems such as leakage, abrasion, and impact, and achieve the effects of less pollution and lower costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

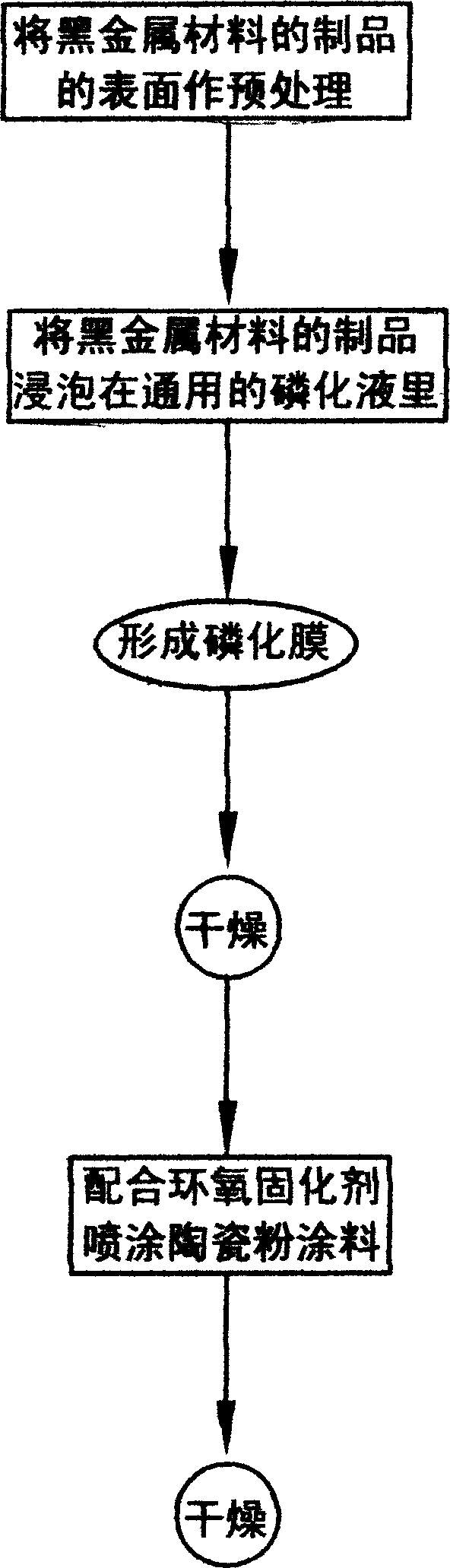

[0014] The anti-corrosion, wear-resistant, impact-resistant and insulated process method of a ferrous metal surface in this embodiment of the present invention complies with relevant technical standards; the process method of this embodiment of the present invention see figure 1 , firstly do some surface pretreatment on the products of ferrous metal materials to remove oil, burrs and rust, which can ensure the normal process of the subsequent process; soak the products of ferrous metal materials in general phosphating solution, Soak for 5 minutes to 60 minutes. In this embodiment, it can be soaked for 20 minutes at room temperature to further remove residual oil stains, burrs and rust while forming a layer of extremely strong adhesion on the surface of ferrous metal materials. Phosphating film; after natural or artificial drying, in the present embodiment, after natural drying, it can be used in conjunction with 5% to 25% epoxy curing agent to spray anti-corrosion, anti-corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com