Motor and drive control device therefor

A technology of motor drive control and current control, which is used in motor generator control, AC motor control, control of electromechanical transmission devices, etc., can solve the problems of increased motor noise, vibration, and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

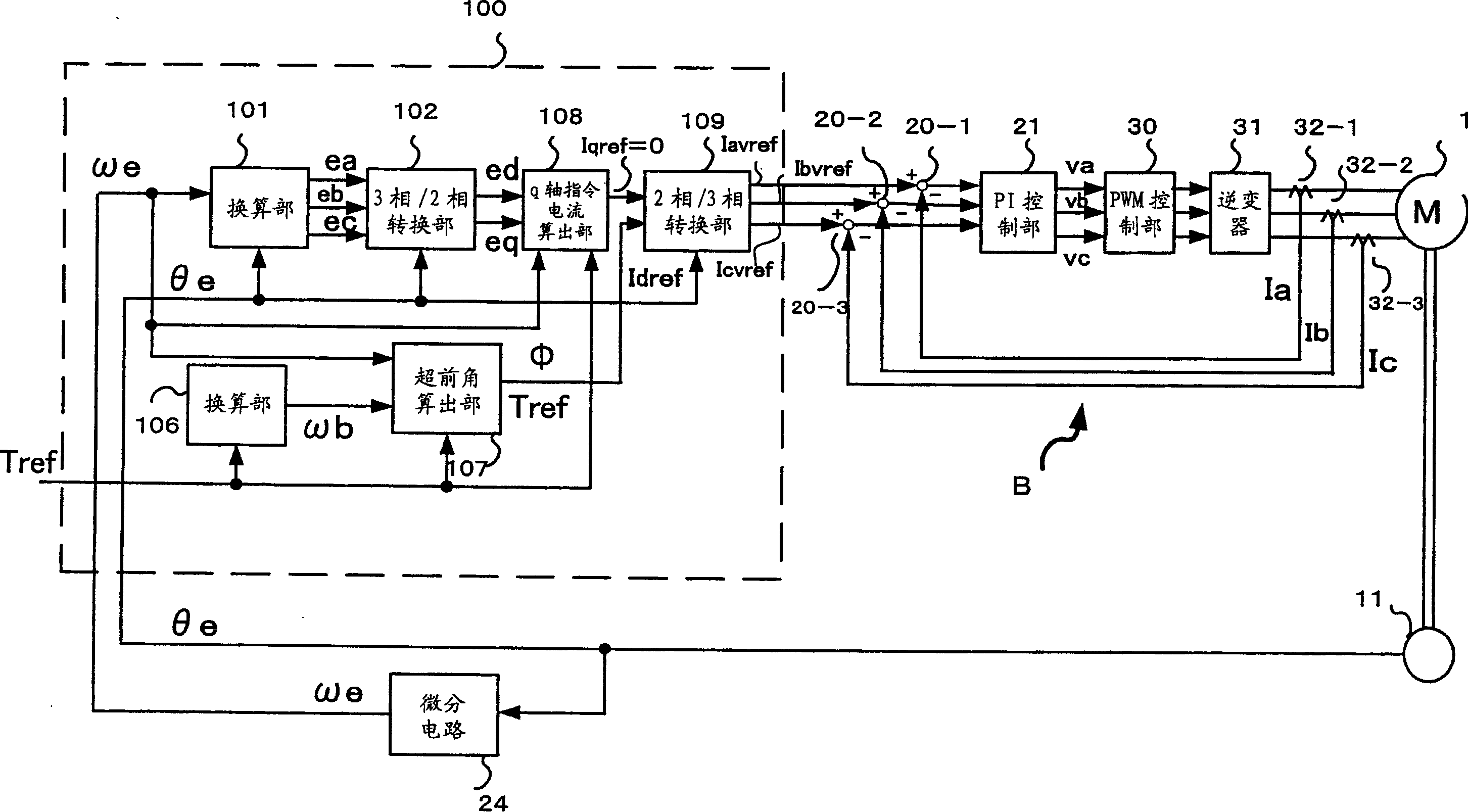

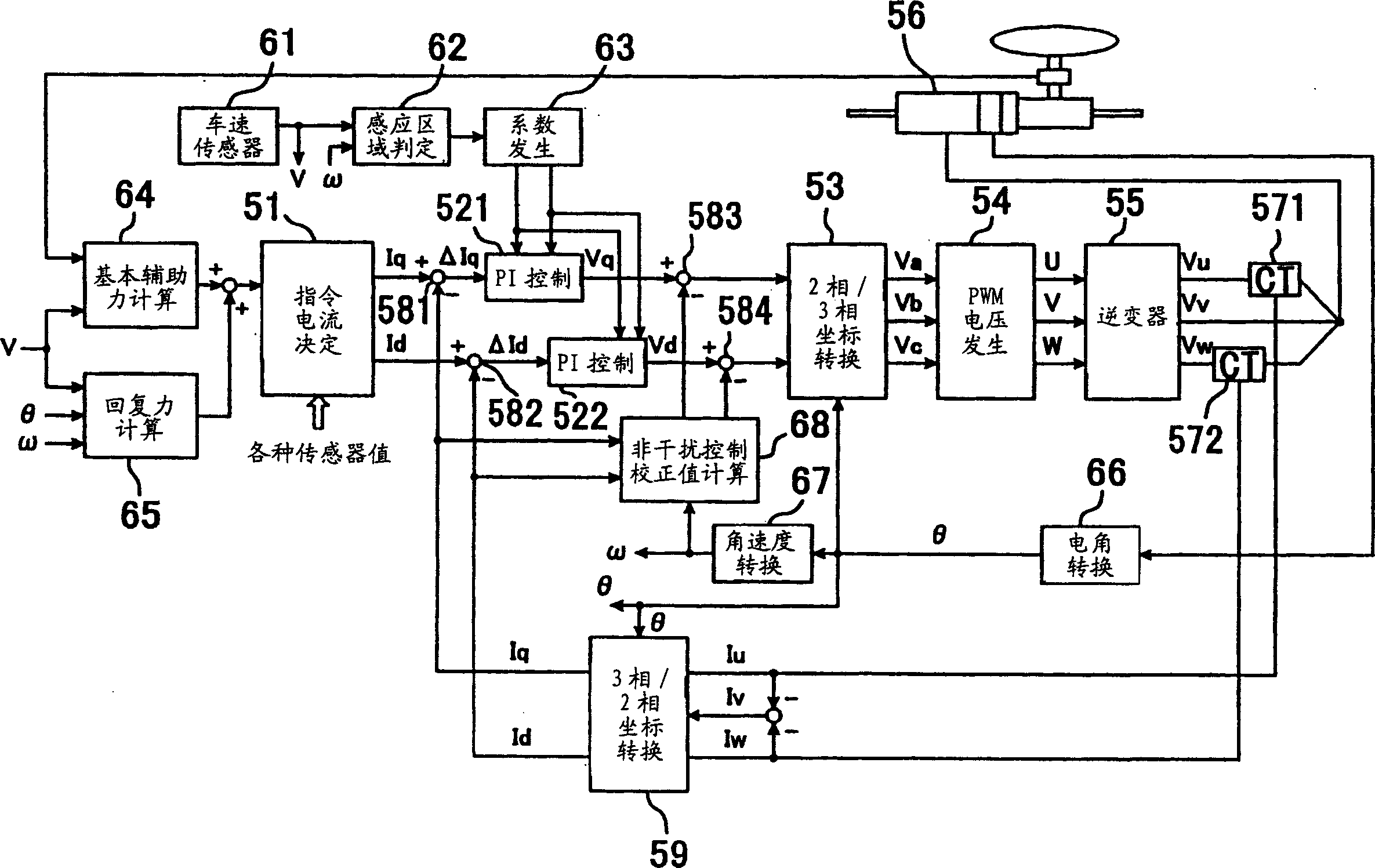

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0045] In this example, a three-phase brushless DC motor is described, but the present invention is not limited thereto, and the present invention can be similarly applied to other motors.

[0046] Such as Figure 4 As shown, the 3-phase brushless DC motor 1 of the present invention has: a cylindrical housing 2; a rotating shaft 4 arranged along the axis of the housing 2 and freely rotatably supported by bearings 3a, 3b at the upper and lower ends. The permanent magnet 5 for motor drive is fixed on the rotating shaft 4; the stator 6 is fixed on the inner peripheral surface of the casing 2 to surround the permanent magnet 5, and is wound with three-phase excitation coils 6a, 6b, 6c. The rotor 7 is constituted by the rotating shaft 4 and the permanent magnets 5 . In the vicinity of one end of the rotating shaft 4 of the rotor 7, an annular permanent magnet 8 for phase d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com