Polyformaldehyde resin made composite fiber

A technology of composite fiber and polyoxymethylene copolymer, which is applied in the direction of fiber treatment, fiber chemical characteristics, conjugated synthetic polymer artificial filament, etc., can solve the problems of low nodule strength and difficult-to-process fibers, and achieve high nodule strength The effect of high retention rate and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

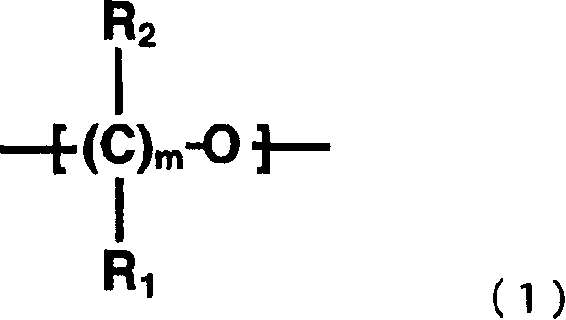

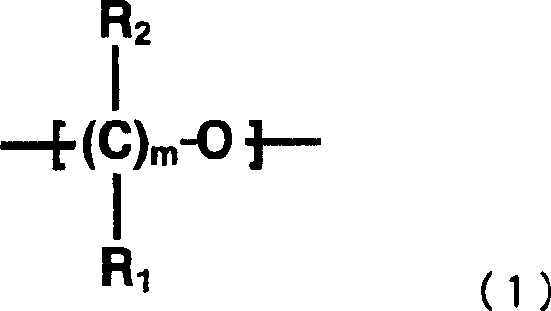

[0048] The polyoxymethylene copolymer (a) and the polyoxymethylene copolymer (b) were produced by the method described below. A continuous mixing reactor consisting of a barrel and a rotating shaft is used, wherein the barrel has a sleeve for passing a hot (cold) medium on the outside, and the section has a shape in which two circles partially overlap, and the rotating shaft has Paddle, while making the two rotating shafts with paddles rotate at 150rpm respectively, add liquid trioxane, cyclic ether or cyclic formal (1,3-dioxolane) as a comonomer ring, 1,4-butanediol formal, diethylene glycol formal), further continuously provide the formal as the molecular weight regulator to the polymerizer, and catalyst boron trifluoride 50ppm (calculated as total monomers), at the same time Bulk polymerization was carried out to prepare polymers having the amounts of comonomers (proportions of oxyalkylene monomers) shown in Table 1, respectively. The reaction product discharged from the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com