Method and device for producing different metal material composite plate and strip

A metal material and production method technology, applied in the field of composite panels, can solve problems such as difficulty in realizing continuous, automated and large-scale production, difficulty in ensuring product quality, and discontinuous process flow, shortening the construction period and eliminating the need for vibration devices. and dummy device, the effect of reducing the segregation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

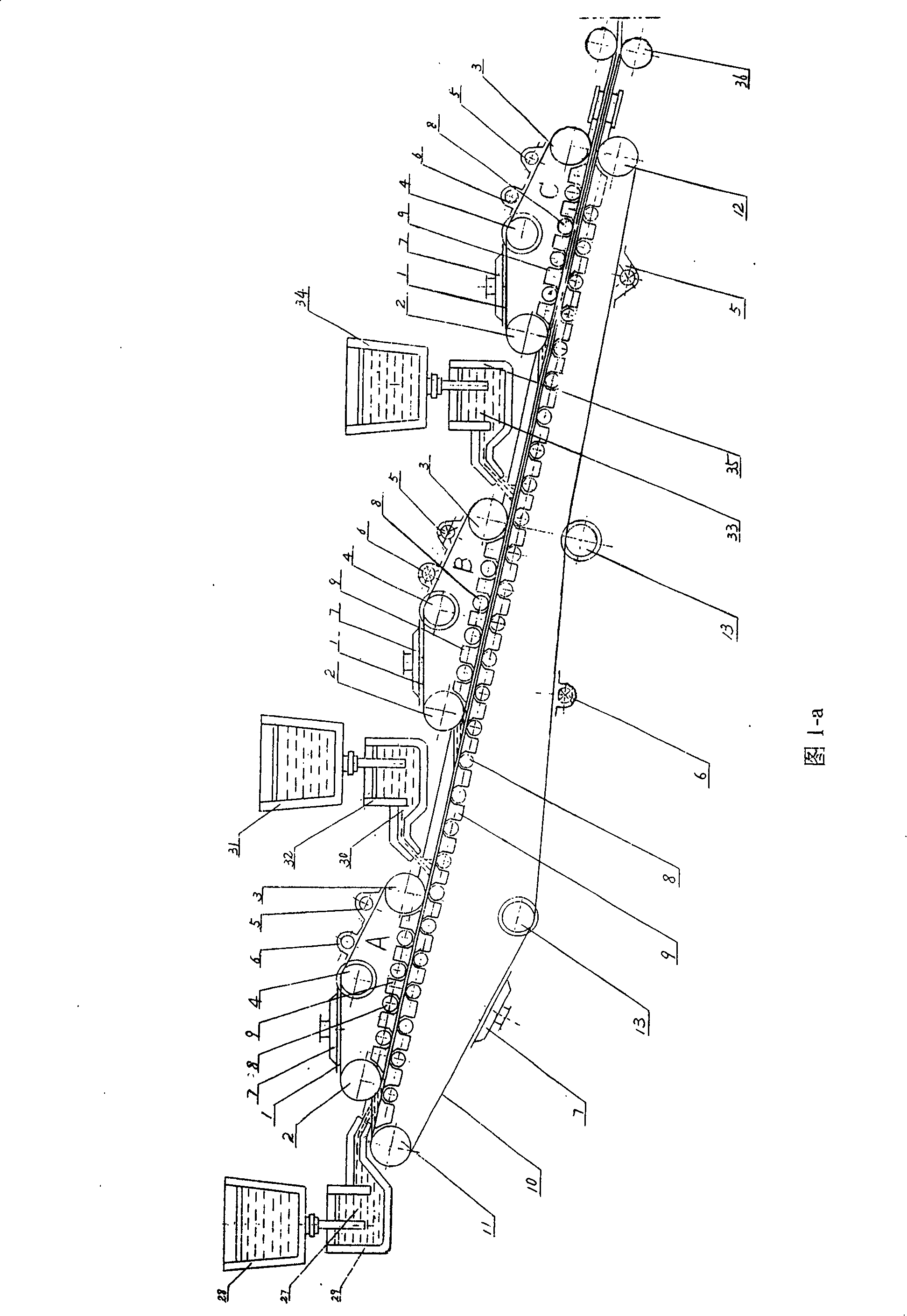

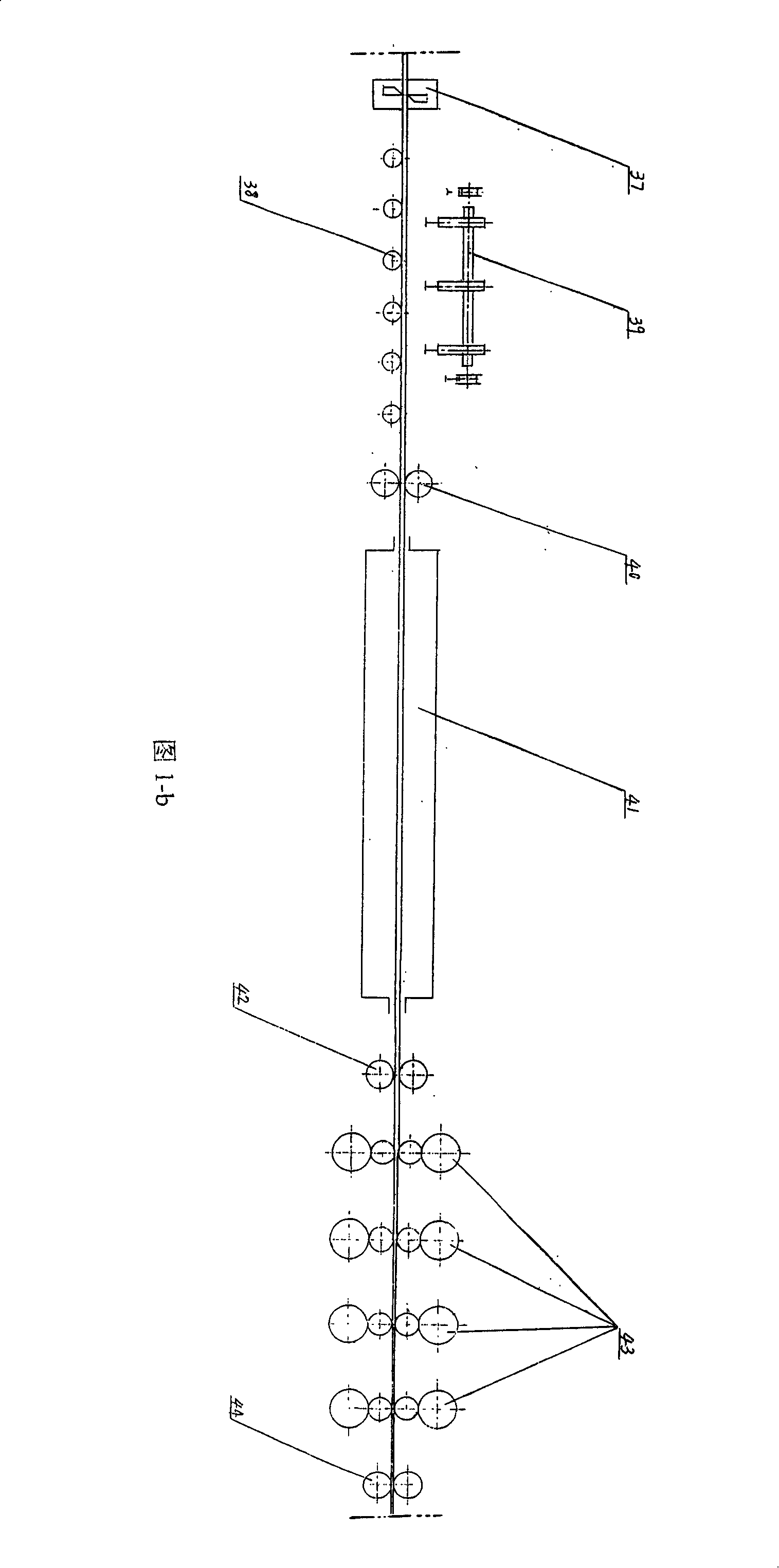

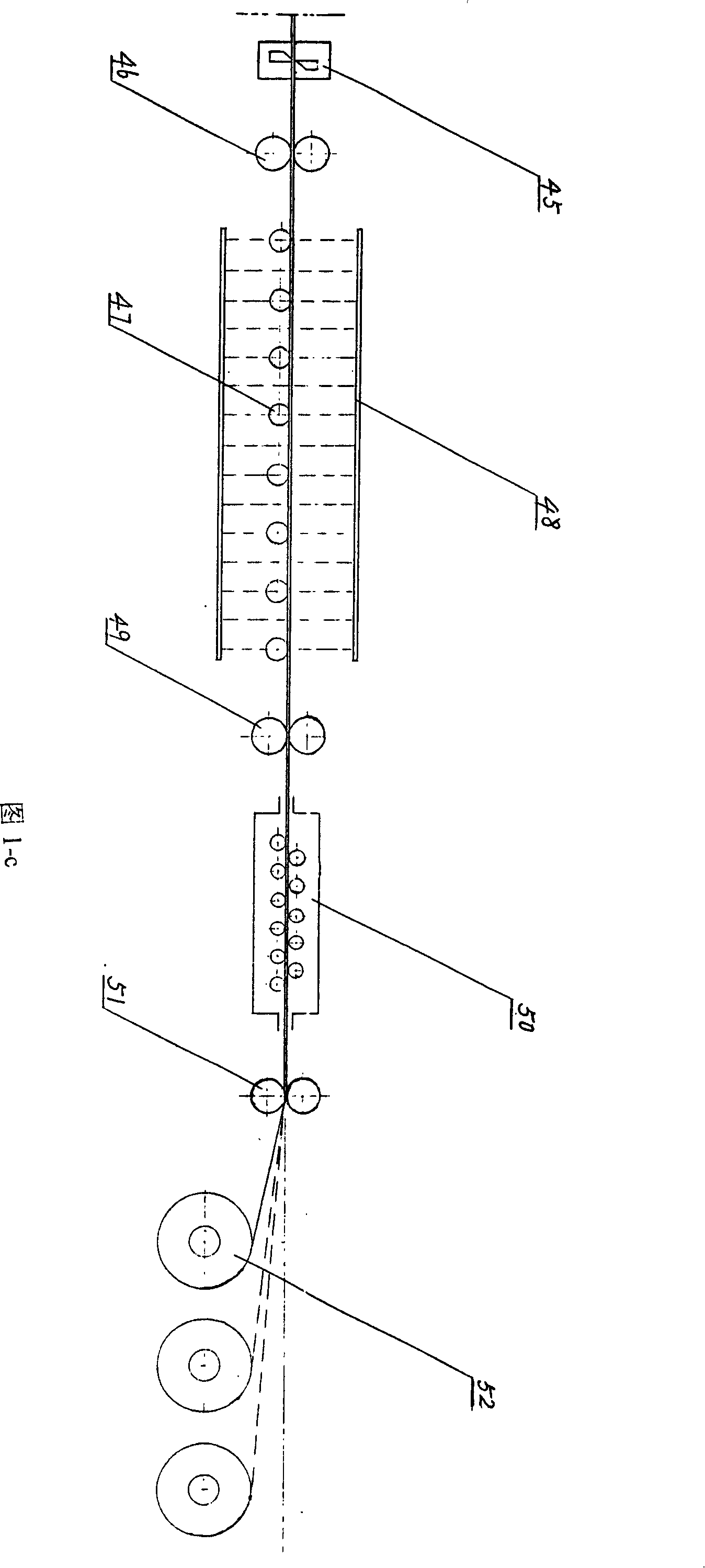

[0030] Taking the production process of stainless steel double-sided composite panels and strips as an example, see Figure 1-a , Figure 1-b , Figure 1-c The stainless steel water 27 is injected into the crystallizer A through the stainless steel water tundish 28 and the stainless steel water casting tank 29, and the stainless steel water moves with the crystallizer A and gradually cools into a stainless steel strip blank, and then the low-carbon molten steel 30 passes through the low-carbon molten steel tundish 31 and the low-carbon molten steel The casting tank 32 is injected into the crystallizer B, and the low-carbon molten steel moves with the mold B to compound on the stainless steel strip blank, and then the stainless steel water 33 of the crystallizer C is injected into the mold C through the tundish 34 of the crystallizer C and the casting tank 35 of the crystallizer C, and then With the movement of the crystallizer C, the stainless steel water 33 is compounded on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com