Technical method for preparing biodiesel using reactive separation process coupling technique

A separation process, biodiesel technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, biological raw materials, etc., to avoid subsequent processing problems and improve speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

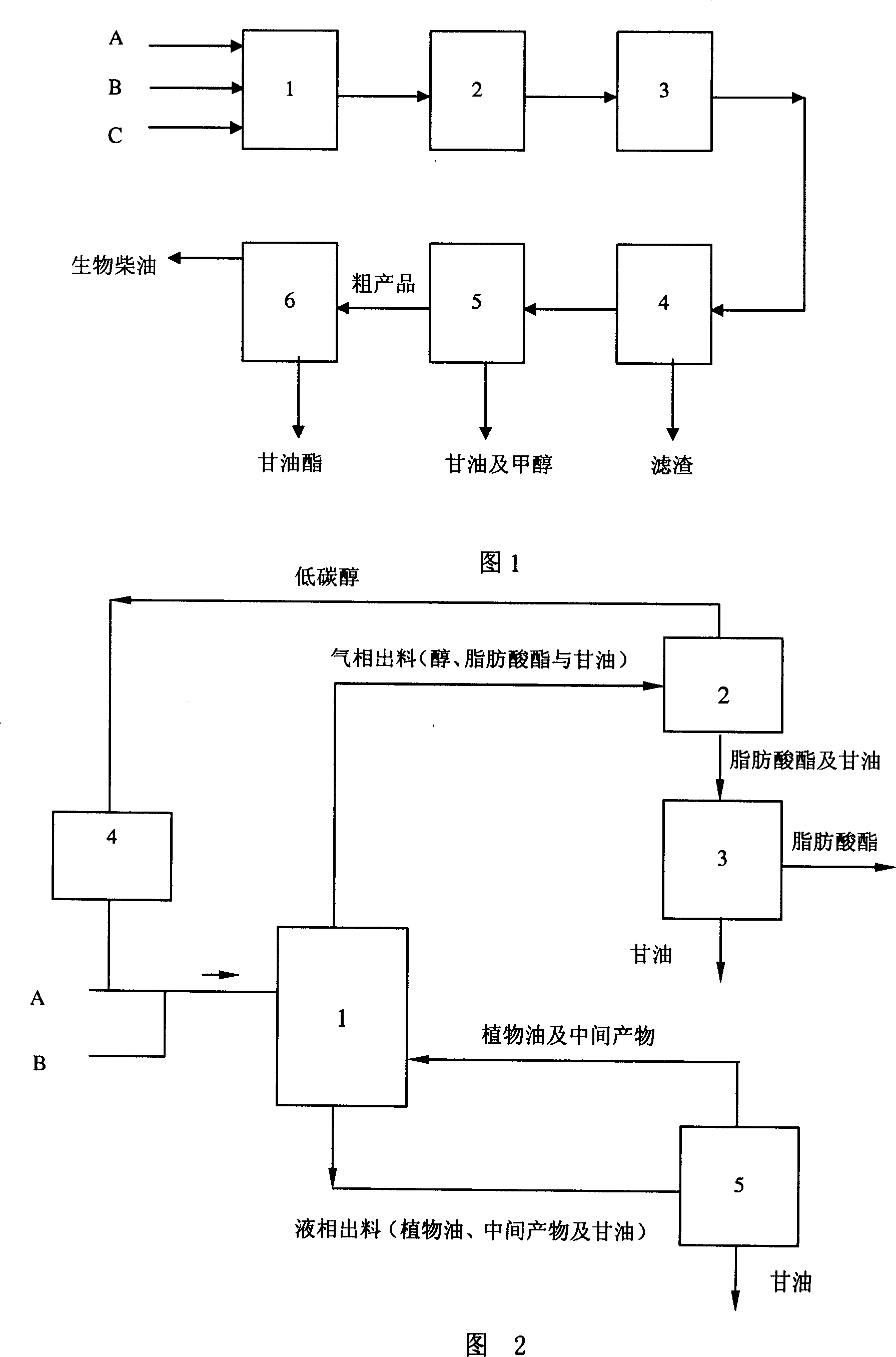

Method used

Image

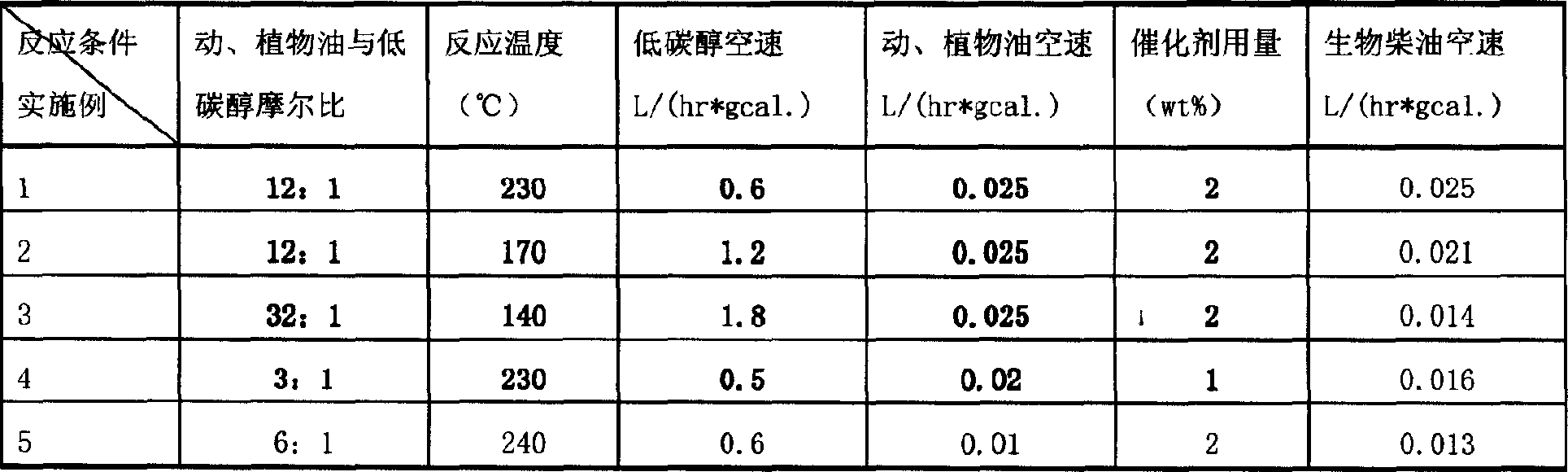

Examples

Embodiment 1

[0040] Example 1 Preparation of Biodiesel by Methanol and Cottonseed Oil Using Reaction Separation Process Coupling Technology

[0041] (1) the reaction of raw material low carbon alcohol and cottonseed oil;

[0042] The raw material low-carbon alcohol (methanol) and cottonseed oil in a molar ratio of 6:1 were fed into the reactor 1 through a pump, and the reaction was carried out under the action of a catalyst and maintained at a temperature of 230°C. At this temperature, methanol with a low boiling point is circulated at a space velocity of 0.6L / (hr*gcal.) (liquid state), and discharged as a gas through the gas phase outlet; the space velocity of the raw oil is 0.025L / (hr*gcal.) ) (liquid);

[0043] (2) the product obtained by the first step reaction is separated;

[0044] The product fatty acid methyl ester and glycerol are taken out of the reactor 1 and entered into the rectifying tower 2 while the methanol is recycled in a large amount;

[0045] The glycerol and mixed ...

Embodiment 2

[0051] Embodiment 2. Process method for preparing biodiesel by using reaction separation process coupling technology from low carbon alcohol and animal fat

[0052] (1) Reaction of raw material low-carbon alcohol and animal fat

[0053] According to the molar ratio of animal oil and low-carbon alcohol (ethanol) is 3:1, add catalyst and raw material animal oil and low-carbon alcohol (ethanol) in reactor 1, and the consumption of catalyst is 1wt% of the raw material oil in the reactor; Maintain at 170°C; the space velocity of circulating low-carbon alcohol is 0.5L / (hr*gcal.); the space velocity of raw oil is 0.02L / (hr*gcal.); carry out the reaction;

[0054] (2) the product obtained by the first step reaction is separated and separated the product of the first step transesterification reaction, so that fatty acid ester and glycerol are separated from the reaction system;

[0055] Keep the reaction temperature constant at 170°C, make the low-boiling low-carbon alcohol flow out f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com