Heat-insulating mortar for external wall of building

A technology for thermal insulation mortar and building exterior walls, applied in the field of thermal insulation mortar, can solve the problems of general thermal insulation performance, difficult construction, low strength, etc., and achieve the effect of good thermal insulation performance, low cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

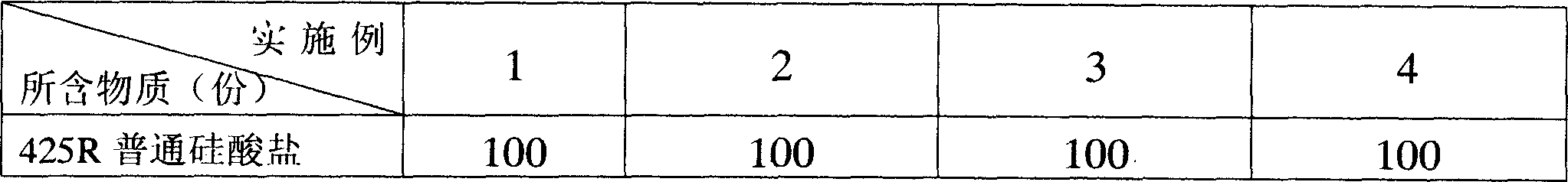

[0020] Embodiment 1: As shown in Table 1, the formula of the building exterior wall insulation mortar that adopts is (by weight): 100 parts of 425R ordinary silicate, 100 parts of primary fly ash, 1.2 parts of superplasticizer, 0.2 parts of micro-foam air-entraining agent, 20 parts of expanded perlite, 10 parts of surface fused expanded perlite, 20 parts of floating beads, 0.8 parts of alkali-resistant short glass fiber, redispersible polyethylene / polyvinyl chloride / polyethylene 8 parts of acrylate terpolymer rubber powder, 0.4 parts of cellulose ether thickener, and 1.2 parts of calcium formate strength activator, after being uniformly mixed in sections by a mechanical mixer, high-performance, low-cost, and environmentally friendly fibers can be obtained Reinforced polymer modified high fly ash content building exterior wall insulation mortar. The physical and chemical performance test results of the mortar are as follows:

[0021] project

Physical and chemical...

Embodiment 5

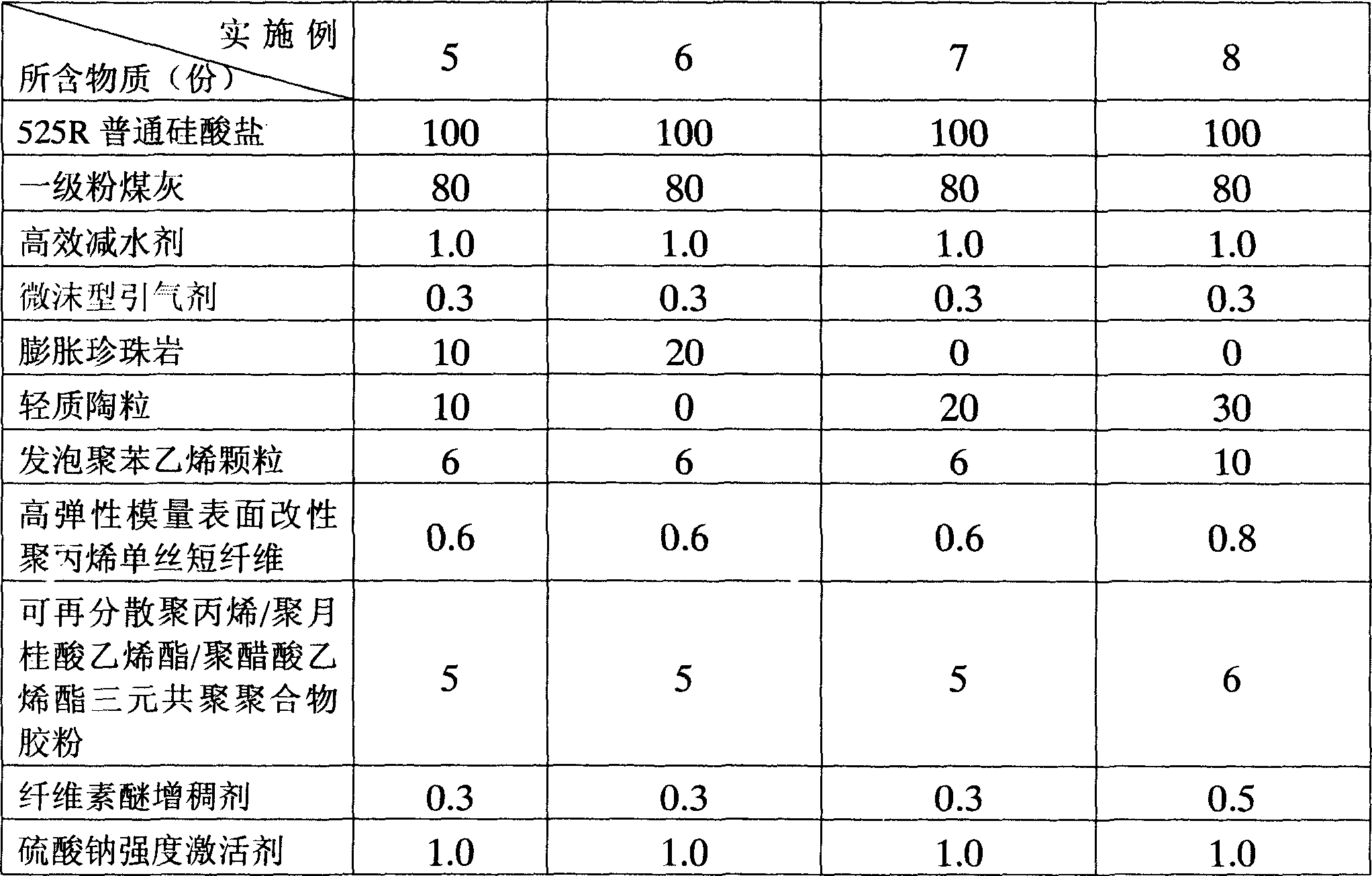

[0026] Embodiment 5: As shown in Table 3, the formula of the building exterior wall insulation mortar that adopts is (by weight): 100 parts of 525R ordinary silicate, 80 parts of primary fly ash, 1.0 part of high-efficiency water reducer, 0.3 parts of micro-foam air-entraining agent, 10 parts of expanded perlite, 10 parts of lightweight ceramsite, 6 parts of expanded polystyrene particles, 0.6 parts of high elastic modulus surface-modified polypropylene monofilament staple fiber, redispersible 5 parts of polypropylene / polyvinyl laurate / polyvinyl acetate terpolymer rubber powder, 0.3 part of cellulose ether thickener, 1.0 part of sodium sulfate strength activator, after being uniformly mixed in stages by a mechanical mixer, that is Obtain high-performance, low-cost, environment-friendly fiber-reinforced polymer modified high fly ash content building exterior wall insulation mortar. The physical and chemical performance test results of the mortar are as follows:

[0027] ...

Embodiment 6-8

[0028] Embodiment 6-8 is the same as embodiment 5.

[0029] The building exterior wall insulation system obtained by using this insulation mortar has low thermal conductivity, excellent construction performance, excellent water retention performance in summer, high early strength, low volume shrinkage, no cracking, low volume moisture absorption, and high adhesion to the wall. , the advantages of high strength in the later stage.

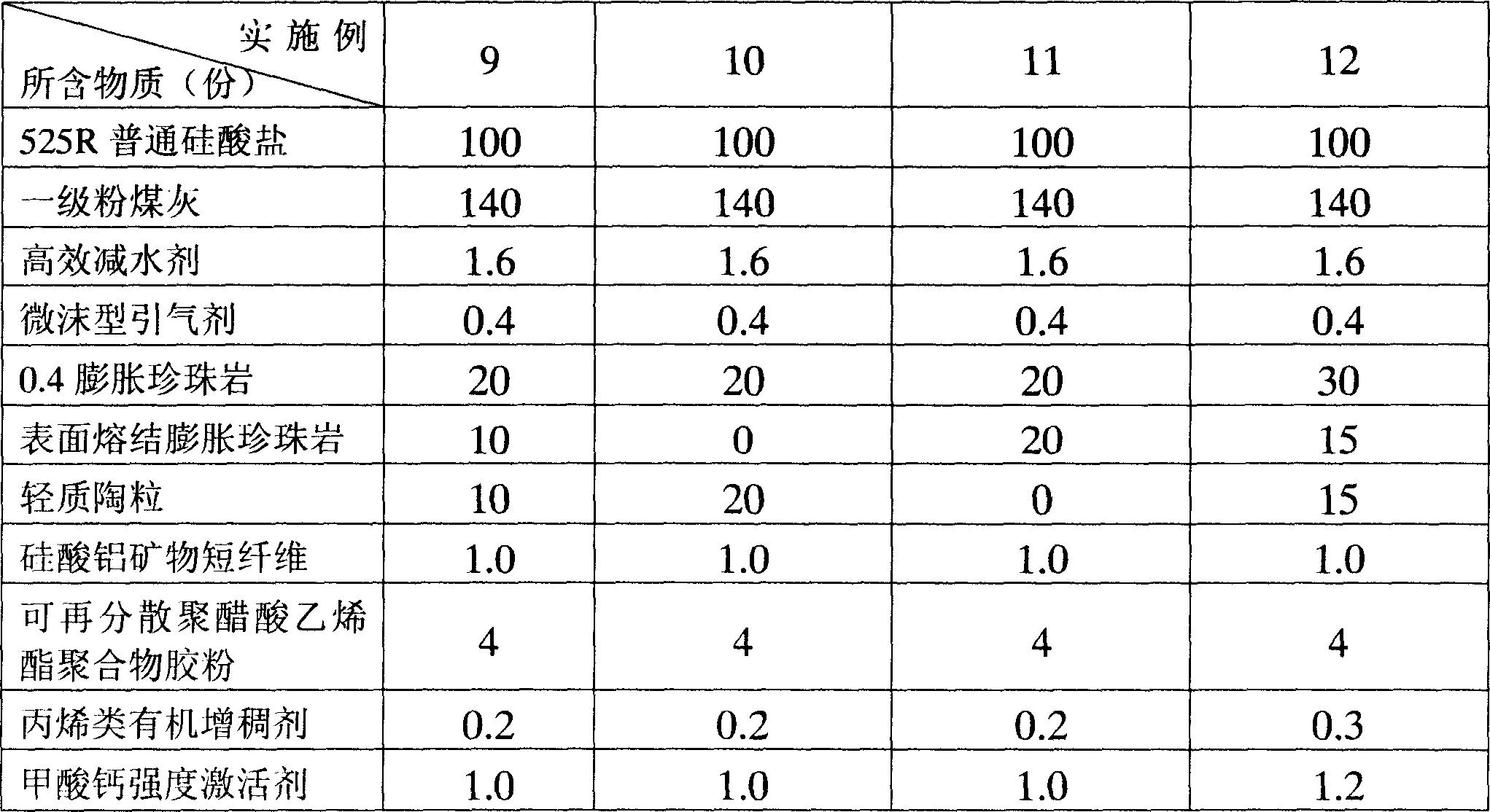

[0030] Table 5 The amount of each substance contained in the building exterior wall insulation mortar (by weight)

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com