Thin film capacitor and method for manufacturing same

A technology of film capacitors and electrodes, applied in the field of capacitors, can solve the problems of sharp reduction and no performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The inventors of the present invention discovered that a single crystal lower electrode and a single crystal dielectric layer can be grown on a single crystal silicon substrate.

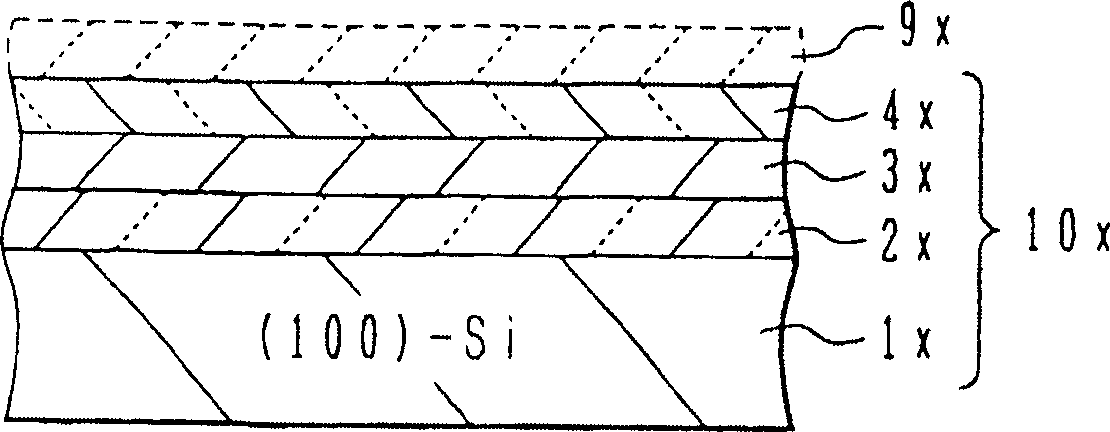

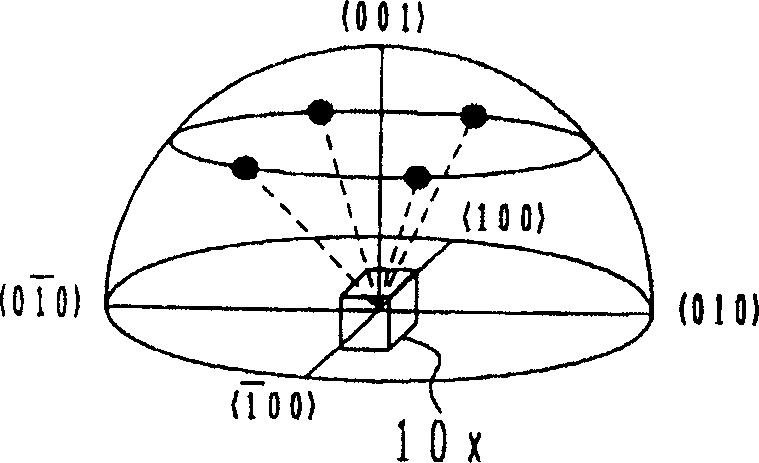

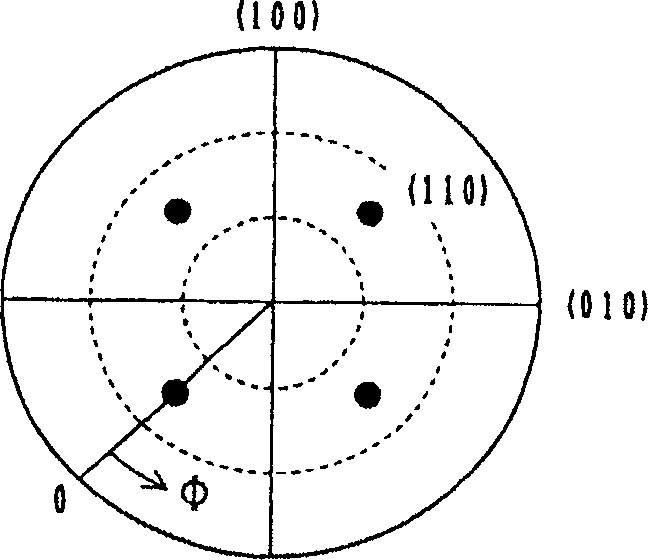

[0040] Figure 1A represents the structure of the sample. A silicon substrate 1x having a (100) plane is prepared. Using SrTiO 3 Sputtering target, containing Ar and O 2 Ar / O 2 At a substrate temperature of 800°C, RF sputtering was used to form SrTiO with a thickness of about 100 nm on the (100) surface of the silicon substrate. 3 The film 2x serves as an intermediate layer of insulating material.

[0041] The substrate temperature was set to 600° C., a Pt layer 3x with a thickness of about 500 nm was formed as a lower electrode layer on the intermediate layer 2x by DC sputtering in an Ar atmosphere, and Ar / O was passed thereon. 2Atmospheric RF sputtering forms ~50 nm thick BaSrTiO of high dielectric constant perovskite oxides 3 Layer 4x acts as a dielectric layer. The sample 10x was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com